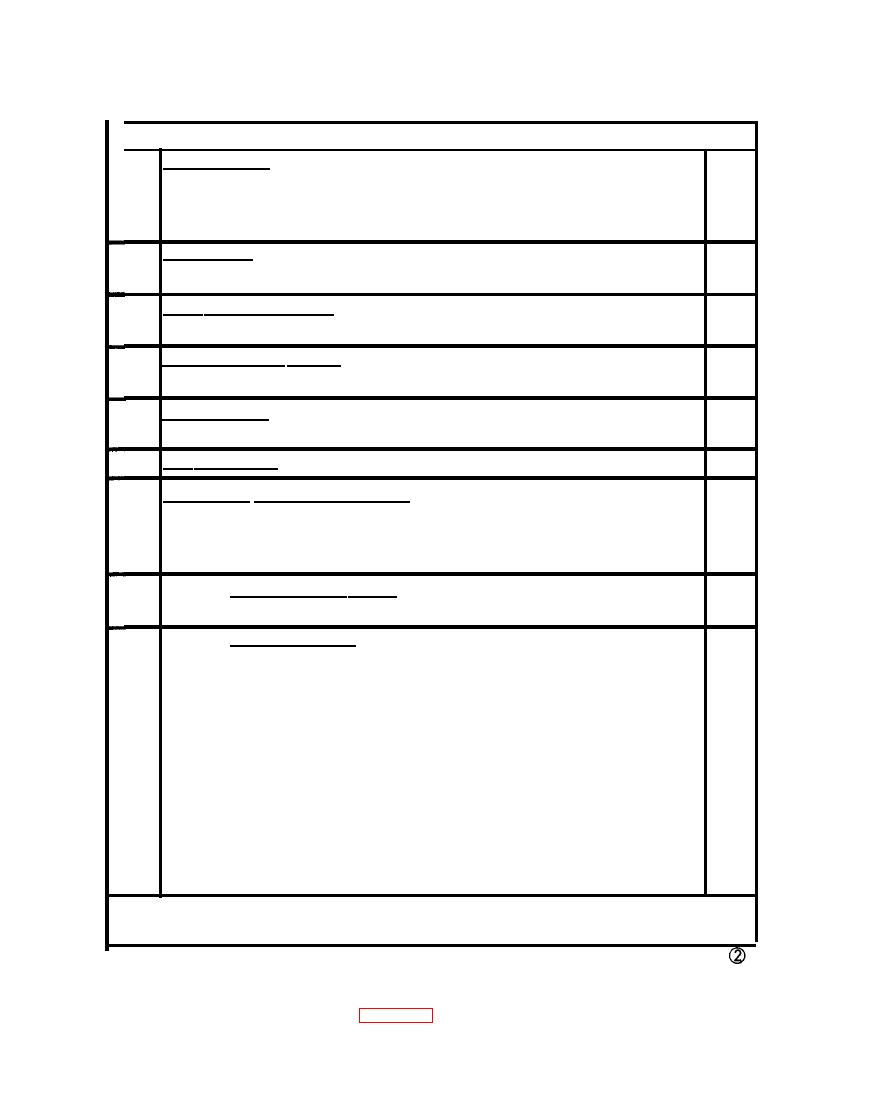

TM 5-4310-227-15

ITEM

PAR RFF

8

S P A R K PLUG. Replace a spark plug that has a cracked insulator or burned

3-44

e l e c t r o d e . Clean and adjust spark plug gap to 0.30 inch. Torque spark plug

to 25 foot-pounds. Replace a lead that is frayed or broken. Clean and

t i g h t e n lead connections.

M A G N E T O . Replace pitted or burned magneto points. Proper gap adjust-

3-46

9

ment is 0.015 inch. (Check adjustment every 500 hours).

10

2-36

F I R E E X T I N G U I S H E R . Inspect for broken seal. Inspect for full charge by

shaking for sound or weight .

11

2-24

S A F E T Y RELIEF V A L V E Inspect for insecure mounting and proper

operation. Maximum pressure is 185 psi.

12

D R A I N C O C K . Inspect for leaks. Make sure it is open before starting eng-

3-90

ine. Replace a defective draincock.

13

3-88

A I R R E C E I V E R Inspect for leaks and damage. Drain condensate.

14

2-13

C O N T R O L S A N D I N S T R U M E N T S : Inspect for damage and loose mounting.

With unit operating, check for proper operation. Normal operating read.

ings for instruments are as follows:

Pressure Gage

140-175

NOTE 1. O P E R A T I O N A L T E S T . During operation observe for any unusual

noise or vibrations.

NOTE 2. A D J U S T M E N T S . Make all necessory adjustments during

operationaI tests.

MEC

4310-227-15/3-5

Figure 3-5-- Continued.

3-14