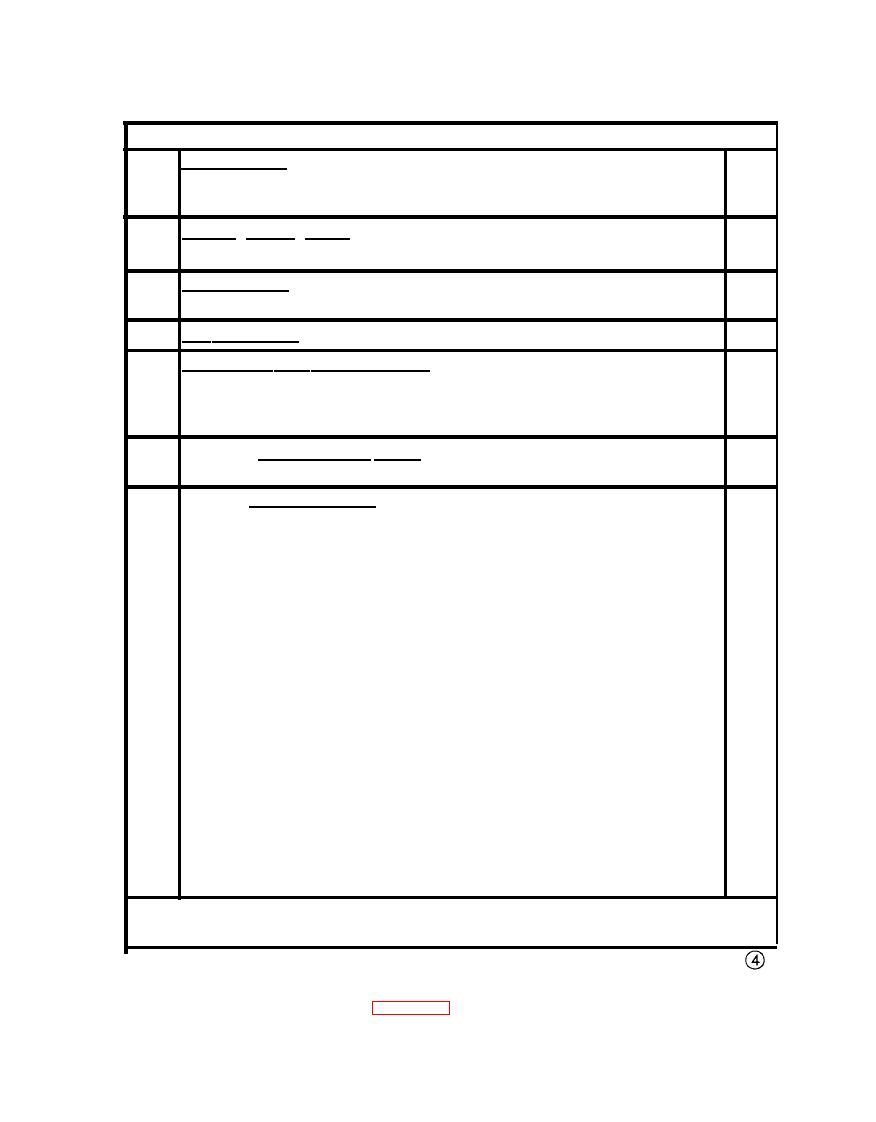

TM 5-4310-227-15

ITEM

PAR REF

8

F U E L T A N K . Add fuel as required. Tighten loose mounting. Re-

3-35

place leaking fuel tank. Replace defective cap gasket. Clean

cup vent.

9

SAFETY RELIEF VALVE Inspect for insecure mounting and proper operation.

2-24

Maximum pressure is 185 psi.

10

D R A I N C O C K . Inspect for leaks. Make sure it is open be for starting eng -

3-90

i n c . Replace a defective draincock.

11

A I R R E C E I V E R . Inspect for leaks and damage. Drain condensate.

3-88

12

2-13

C O N T R O L S A N D I N S T R U M E N T S : Inspect for damage and loose mounting.

With unit operating, check for proper operation. Normal operating read

ings for Instruments are as follows;

140-175

Pressure Gage

O P E R A T I O N A L T E S T . During operation observe for any unusual

NOTE 1.

noise or vibrations.

NOTE 2. A D J U S T M E N T S . Make all necessary adjustments during opera-

tional tests.

MEC 4310-227-15/3-5

Figure 3-5--Continued.

3-16