TM 5-4310-227-15

(7) Replace a defective mounting gasket

and magneto.

c. Installation and Timing.

(1) Secure the vent screen and vent cover

(38) to the side of the magneto (25)

with the lockwasher and screw (37).

Install the vent screen and vent cov-

er on the opposite side of the magneto

in a similar manner.

(2) Secure the ignition shield (13) and

m e t a l gasket (39) to the magneto

with the four lockwashers (11) and

screws (12).

Note.

If the crankshaft was rotated

after remova of the magneto, it will be

necessary to rest the engine timing gears

to properly engage the magneto drive

gear. If the crankshaft has not been dis-

turbed, the magneto may be installed as

described in (6) through (10) below.

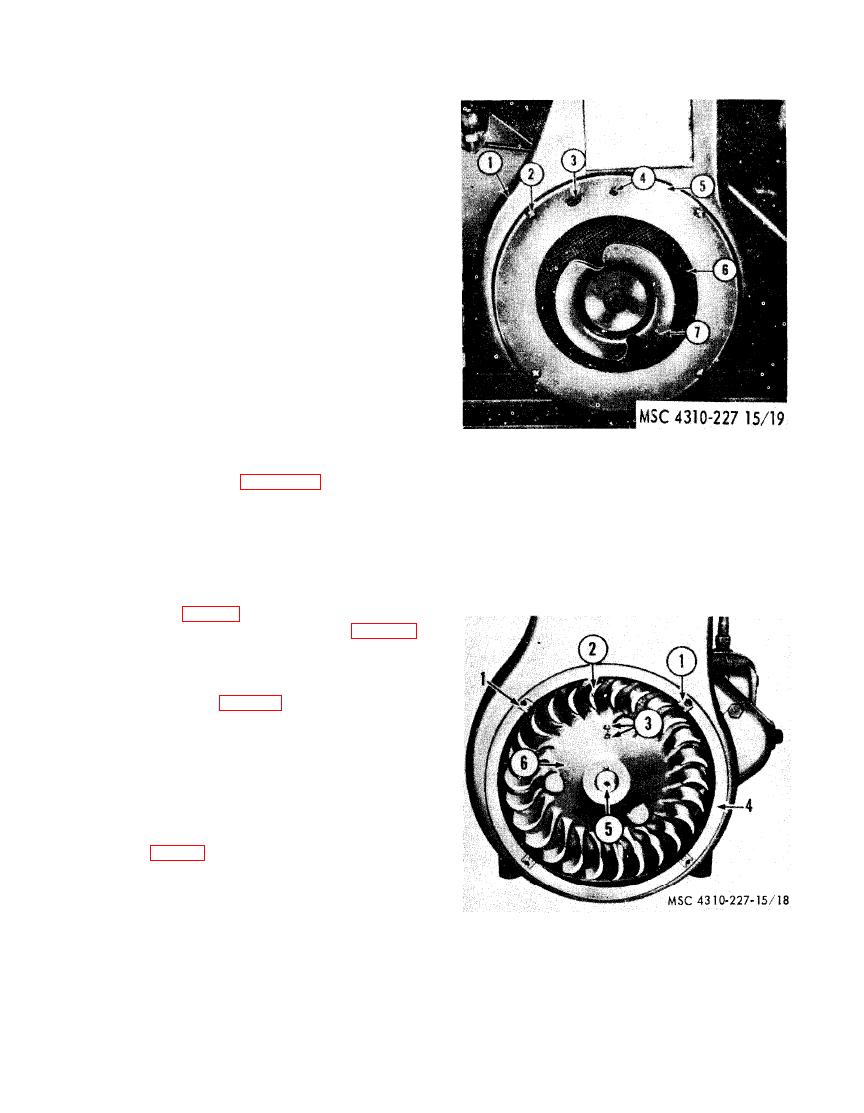

1 Air shroud

(3) Reset the timing by first removing the

Screw, machine, 1/4-20 X 1/2 in. (4 rqr)

2

spark plug (para 3-31).

20 timing hole

3

Top center inspection hole

4

(4) Place a thumb over the spark plug

5

Rim

hole and slowly rotate the engine un-

Screen

6

til the piston is on the compression

7

Starting pulley assembly

stroke and pressure begins to build

up under the thumb.

(5) Look through the air shroud screen

(6, fig. 3-11) and position the fly-

wheel timing mark D-C (3, fig. 3-12)

at the top. The flywheel air vane tim-

ing mark X (2) should then appear

centered in the top center inspection

hole (4, fig. 3-11) in the air shroud

rim (5).

Note. The flywheel timing mark D-C

indicates when the piston is sit top dead

center of the compression stroke. The air

vane timing mark may be in the form of

white paint, or a stamped X, or both.

(6) Position the magneto drive gear (27,

the timing mark (X) (26) will appear

in the gear housing inspection hole.

P o s i t i o n the magneto (25) on the

cylinder and crankcase assembly (18)

with the timing mark centered in the

1

Nut, sheet, spring, No. 14A (4 rqr) 4 Air shroud

Flywheel air vane timing mark (X) 5 Crankshaft

2

inspection hole.

6 Flywheel

Flywheel timing mark (D-C)

3

(7) Secure the magneto (25) to the top

side of the cylinder and crankcase as-

3-36