TM 5-4310-275-14

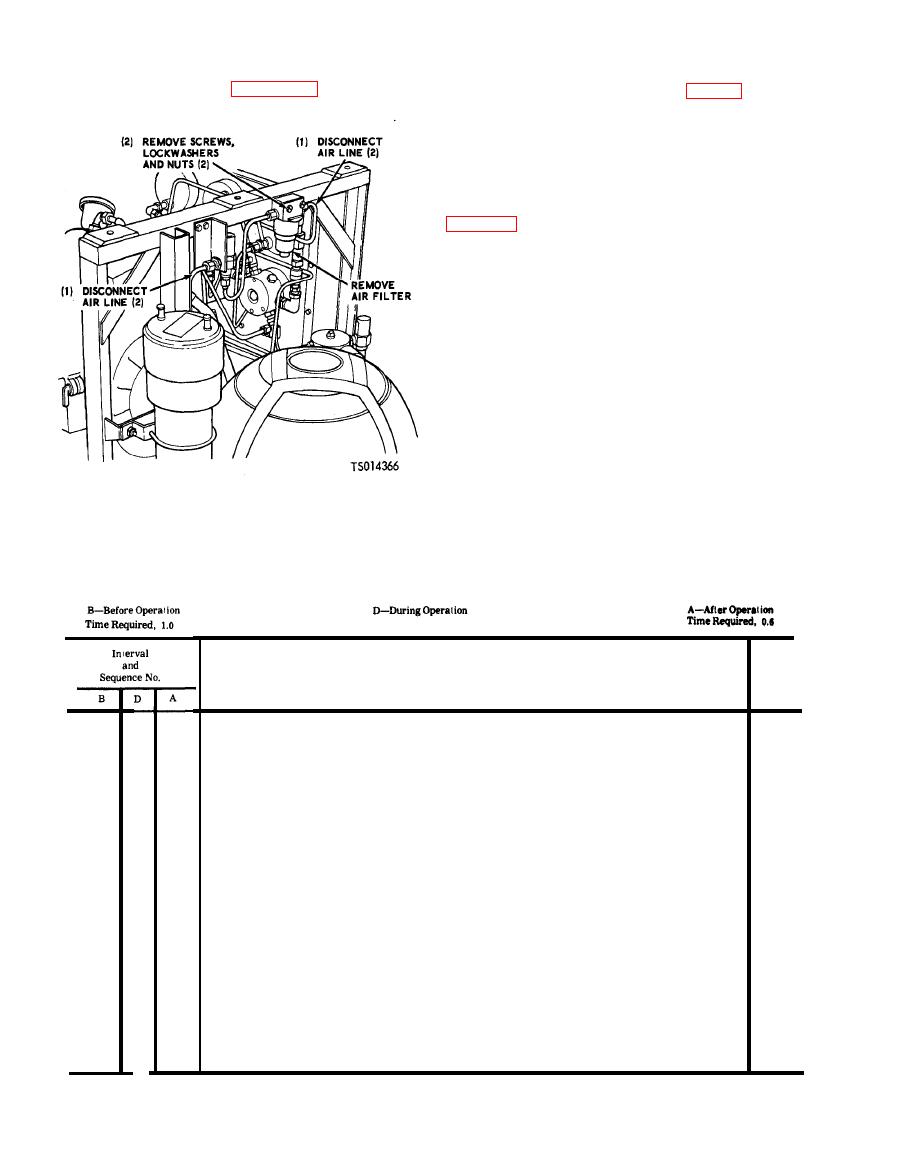

(2) Service or replace the air line filter at 100

(3) Clean or replace the compressor air in-

hour intervals. Refer to Figure 3-3.

take filter at 50 hour intervals (fig. 3-6).

This paragraph contains an illustrated tabulated

listing of preventive maintenance services which

must be performed by the operator. The item

numbers are listed consecutively and indicate the

sequence of minimum requirements. Refer to

vices.

installation.

Work

Item to be inspected

time

Procedure

(M H)

1

ENGINE FUEL FILTER

0.2

Service as required.

FUEL TANK

2

0.2

Check fuel level. Inspect for leaks. Inspect fuel tank cap for closed vent hole.

ENGINE AIR CLEANER INDICATOR

0.1

3

Check for red warning signal.

TIRES AND TUBES

0.2

4

Inspect for proper inflation, cuts breaks, and flat spots. Replace missing valve caps.

ENGINE OIL DIPSTICK

5

0.1

Check engine lubricating oil level. Add oil as required.

0.2

6

COMPRESSOR AIR INTAKE FILTER

Inspect for dirt and damage. Clean or replace as required. .

0.2

AIR COMPRESSOR

7

Clean cooling fins. Check air lines for leaks.

0.1

8

SIGHT LEVEL GAGE

Check compressor lubricating oil level. Add oil as required.

9

0.1

AIR SYSTEM

Drain the air system after daily use.

AIR RECEIVER

0.2

10

Inspect for worn harness assembly. Check for secure mounting.