TM 5-4310-278-15

TROUBLE SHOOTlNG

Section V.

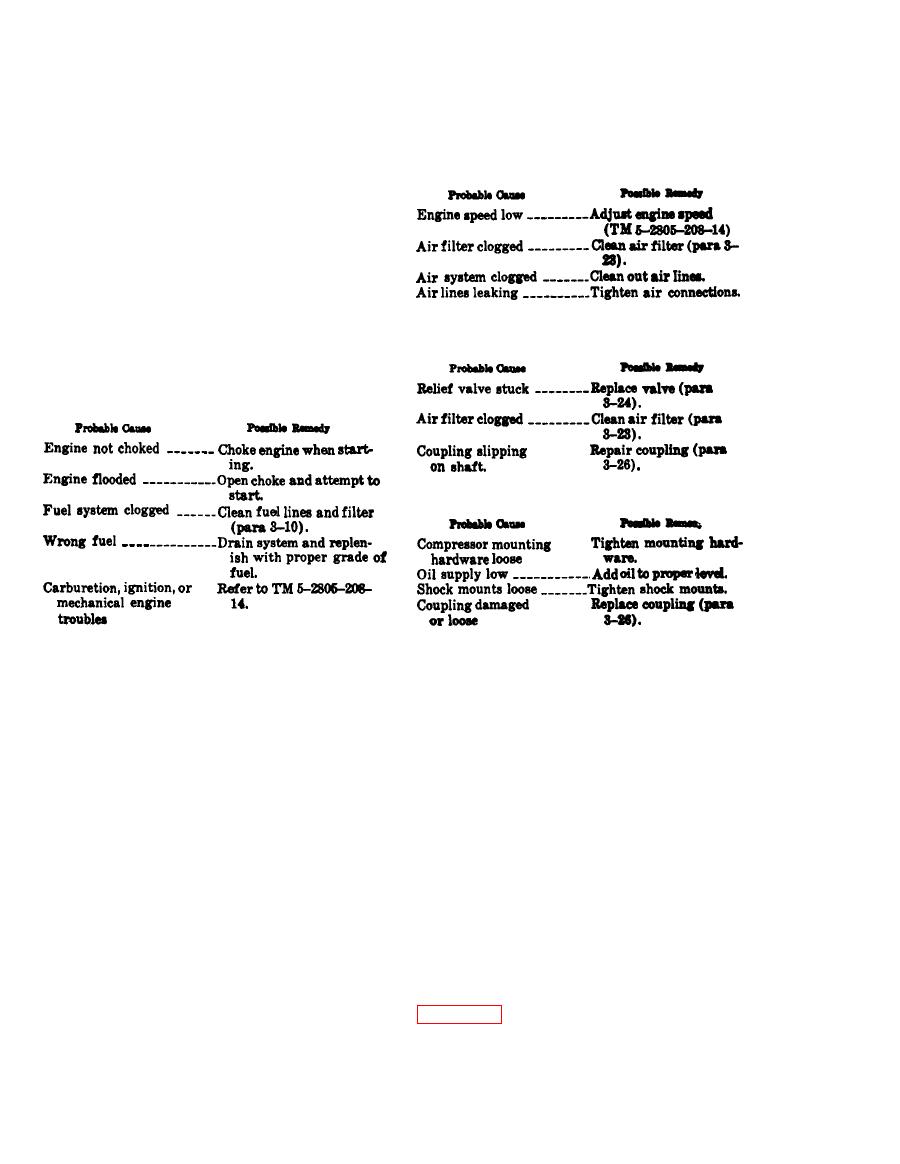

3-12. General

Rated Capacity

This section provides information useful in

diagnosing and correcting unsatisfactory oper-

action or failure of the rotary compressor and its

components. Each trouble system stated is

followed by a list of probable causes of the

trouble. The possible remedy recommended is

described opposite the probable cause. Any

trouble beyond the scope of organizational

maintenance shall be reported to direct sup-

Output

port maintenance. Refer to TM 6-2805-208-

14 for engine troubleshooting.

Section VI. RADIO INTERFERENCE SUPPRESSION

Proper Suppression

Components

Essentially, suppression is attained by provid-

Radio interference suppression components are

ing a low resistance path to ground for the

provided on the engine only. Refer to TM 5-

stray currents. The methods used include

2805-208-14 for description and replacement

shielding the ignition and high-frequency wires,

procedures. Bond strap supplied on frame

grounding the frame with bonding straps, and

using capacitors and resistors.

grounds engine to frame.

Section VII. FUEL SYSTEM

3-19. General

This section contains the maintenance in-

a. Removal

structions for the engine fuel system compo-

(1) Remove fuel tank as illustrated in

nents which are not described in TM 5-2805-

208-14. It includes coverage of the fuel tank,

fuel filter, and fuel lines and fittings.

(2) Remove fuel tank cap and strainer.