TM 5-4310-335-14

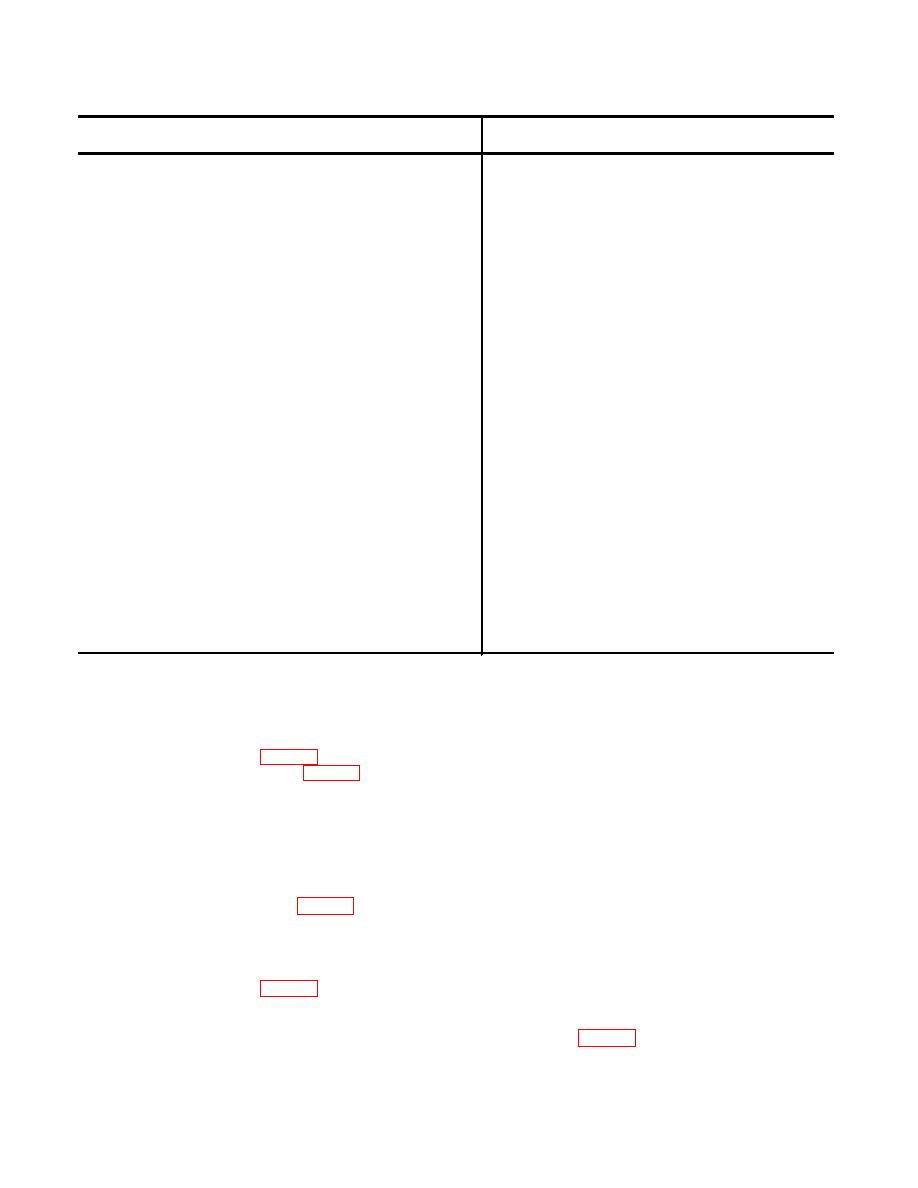

Table 5-2. Recommended Wrench Torques and Tolerances

Torque Value

Torque Value

Component

inch-pounds

Component

inch-pounds

Moisture Separator:

Bolts, Compressor Mounting

Cylinder

50 ( .5809 kg-m)

Adapter

40 ( .4702 kg-m)

Cap, Safety

1200 ( 13.83 kg-m)

65 ( .7607 kg-m)

(retorque after

Plug, Piston Pin Assembly

200 ( 2.3234 kg-m)

24 hours)

250 ( 2.7660 kg-m)

Seat

50 ( .5809 kg-m)

Compressor/Cooler Assembly:

65 ( .7607 kg-m)

Nut, Fan

150 ( 1.7288 kg-m)

Locknut

500 ( 5.78 kg-m)

170 ( 1.1964 kg-m)

Nuts, Bulkhead

65 ( .7607 kg-m)

Nuts, 1st Intercooler

190 ( 2.1851 kg-m)

80 ( .9404 kg-m)

210 ( 2.6969 kg-m)

Sphere:

Nuts, 2nd Intercooler

135 ( 1.5328 kg-m)

Plug

375 ( 4.33 kg-m)

150 ( 1.7288 kg-m)

Safety Plug

275 ( 3.17 kg-m)

Nuts, 3rd Intercooler

135 ( 1.5328 kg-m)

(retorque after

150 ( 1.7288 kg-m)

24 hours)

Nuts, Aftercooler Tube

135 ( 1.5328 kg-m)

Basic Compressor:

150 ( 1.7288 kg-m)

Screw, Protective Cap

17 ( .2075 kg-m)

Bolts, Compressor

22 ( .2766 kg-m)

to Engine Mounting

60 ( .6915 kg-m)

Screw, 1st head

30 ( .3596 kg-m)

80 ( .9404 kg-m)

35 ( .4011 kg-m)

Cart, Frame Assembly:

Screw, 2nd head

60 ( .6915 kg-m)

Bolts, Engine Mounts to Engine 60 ( .6915 kg-m)

65 ( .7607 kg-m)

80 ( .9404 kg-m)

Screw, 3rd head

30 ( .3596 kg-m)

Bolts, Engine Mounts to Frame 0 ( . 6915 kg-m)

40 ( .4702 kg-m)

80 ( .9404 kg-m)

Nuts, Sphere Mount Plate

120 ( 1.3830 kg-m)

Screw, 4th head

60 ( .6915 kg-m)

Nuts, Front and Rear Support

65 ( .7607 kg-m)

Brackets to Frame

120 ( 1.3830 kg-m)

Screw, Oil Pump Housing

25 ( .2904 kg-m)

Nuts, Control Oil Supply Tubing

35 ( .4011 kg-m)

Connectors

11 ( .1259 kg-m)

Screw, Adapter Splined Crankshaft

235 ( 2.7245 kg-m)

13 ( .1521 kg-m)

Section IV. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS AND ASSEMBLIES

5-8 Roof Assembly

a Removal.

(1) Disconnect all lines and fittings, (air, fuel and oil), connected to the roof assembly and its

components (fig. 5-5).

(2) Remove locknuts (1, fig. 5-1), flat- washers (2 and 3) and capscrews (4) securing roof assembly to

the frame and axle assembly.

(3) Remove locknuts (5), flatwashers (6 and 7) and capscrews (8) securing roof assembly (9) to the

frame and axle assembly.

b Inspection. Inspect metal parts for dents, breaks and cracks, burrs, rough edges or other damage.

Repair any damage or replace parts which obstruct moving parts or could cause damage to the

equipment.

c Installation

(1) Install locknuts (5, fig. 5-1), flat- washers (6 and 7) and capscrews (8) securing roof assembly (9)

to the frame and axle assembly.

(2) Install locknuts (1), flatwashers (2 and 3) and capscrews (4) securing roof assembly (9) to the

frame and axle assembly.

(3) Connect all lines and fittings, (air, fuel and oil), connected to the roof assembly and its

components (fig. 5-5).

5-9 Dehydrator

a Removal.

(1) Disconnect pipe elbows, dehydrator inlet and outlet (1 and 2, fig. 5-2).

(2) Remove locknuts (3), flatwashers (4), spacers (5), flatwashers (6), bolts (7), and bracket (8).

(3) Remove locknuts (9), flatwashers (10 and 11), bolts (12) and bracket (13).

(4) Remove nuts (14), flatwashers (15) and U-bolt (16) freeing dehydrator (17) from frame and axle

assembly.

5-9