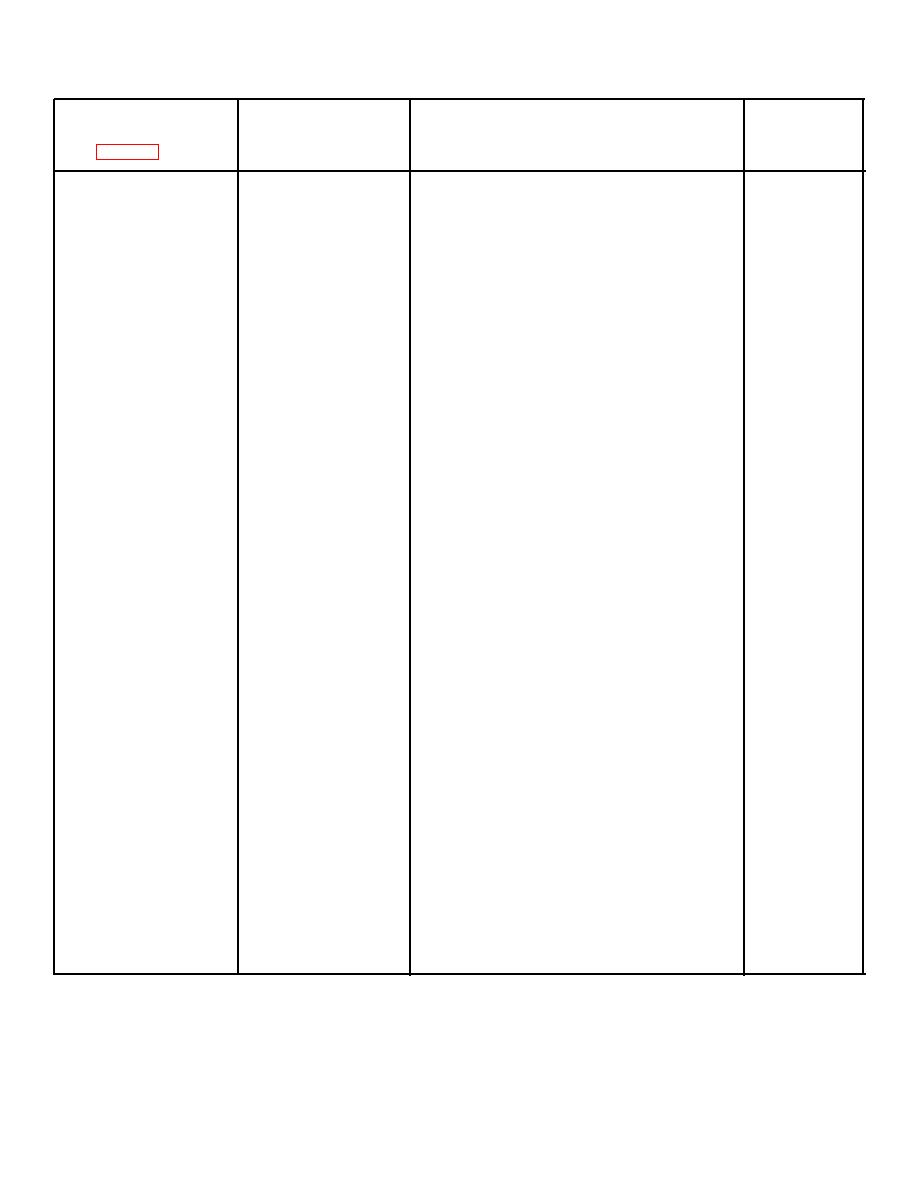

TABLE II. INSPECTION

Part Name &

Index No.

Type of

Acceptable

Inspection

Inspection Procedure

Defects

Noise Filter (1)

Electrical

Check for continuity between the

None

two terminals. Check that there is

no continuity between either

terminal and the case.

Fan (8)

Visual

Examine blades for cracks, nicks,

None

dents or bends.

Brushes (11)

Visual

Inspect for chipped or cracked

None

carbon. See that leads are riveted

tightly to brush, and are not

frayed or broken. Replace brush

if less than 0.49 inch long.

Bearings (33, 44)

Visual

Inspect for roughness, binding

None

or lack of lubrication.

Armature (42)

Visual

Examine for rough or pitted

None

commutator, and dark or burned

commutator bars.

Dielectric

Using 500 volts AC, test for a

None

Test

ground between each commutator

bar and armature shaft (not at

bearing surfaces); must not show

continuity. Test for a short

circuit or open windings with a

standard growler.

Stator Assembly

Visual

Inspect field windings (49 and 51)

None

(47 through 53)

for burned or damaged insulation,

for loose or open connections.

Dielectric

Using 500 volts AC, test for a

None

Test

ground between positive field

terminal and housing; must not

show continuity. This test must

be made with the radio noise

filter electrically insulated from

the motor frame, or prior to

installation of radio noise

filter.

Brush Rigging

Visual

Check for cracks, defective spring,

None

Assembly

brush box or other obvious defects.

(14 through 29)

A-5