c. In the shortest time possible, place

4. Install insert (41) and press pin (40) until it

stator (lead end up) in an oven and

bottoms into end bell (39), if they were

bring parts to 290 - 325F (143.3 -

removed.

162.8 C).

5. Insert the assembled armature into the

d. Repeat above step (b).

assembled end bell. Then install the end

bell on housing (53).

e. In the shortest time possible, place

stator (lead end up) in oven at 290

6. Insert rod assemblies (38) with washers

- 325F (143.3 - 162.8C). The

(37) through end bell assembly, then

stator temperature must reach 290

install insulators (36).

- 300F (143.3 - 148.9C) for 1-3/4

to 2 hours.

7. Align the scribe mark on end bell (30) with

scribe mark on housing (53). Tap end bell

5. Ground test using 500 volts AC.

into place with rawhide mallet. Push rod

assemblies (38) through end bell (30) and

C. Lubrication.

install nuts (34) and washers (35). Torque

nuts (34) to 12-15 inch-pounds.

No lubrication required.

Ball bearings are

8. Install bearing (33), retainer (32) and

sealed units, lubricated at the factory and

screws (31) torqued to 20-25 inch-pounds.

cannot be relubricated.

Use sealing compound primer and sealant

on threads.

9. Install inserts (29) into terminal (28) if they

were removed, then with brush holder

(27), washer (26) and screw (25), fasten

the terminal to insulator ring (16) with the

deep chamfer on the I.D. of the insulator

on the same side as the holder (27).

Across the insulator 180, repeat these

instructions and install another terminal

(28) and holder (27). These are positive

brush holders.

10. Install brush holder (24), screw (23),

washer (22) and nut (21). Install the

remaining brush holder in a like manner,

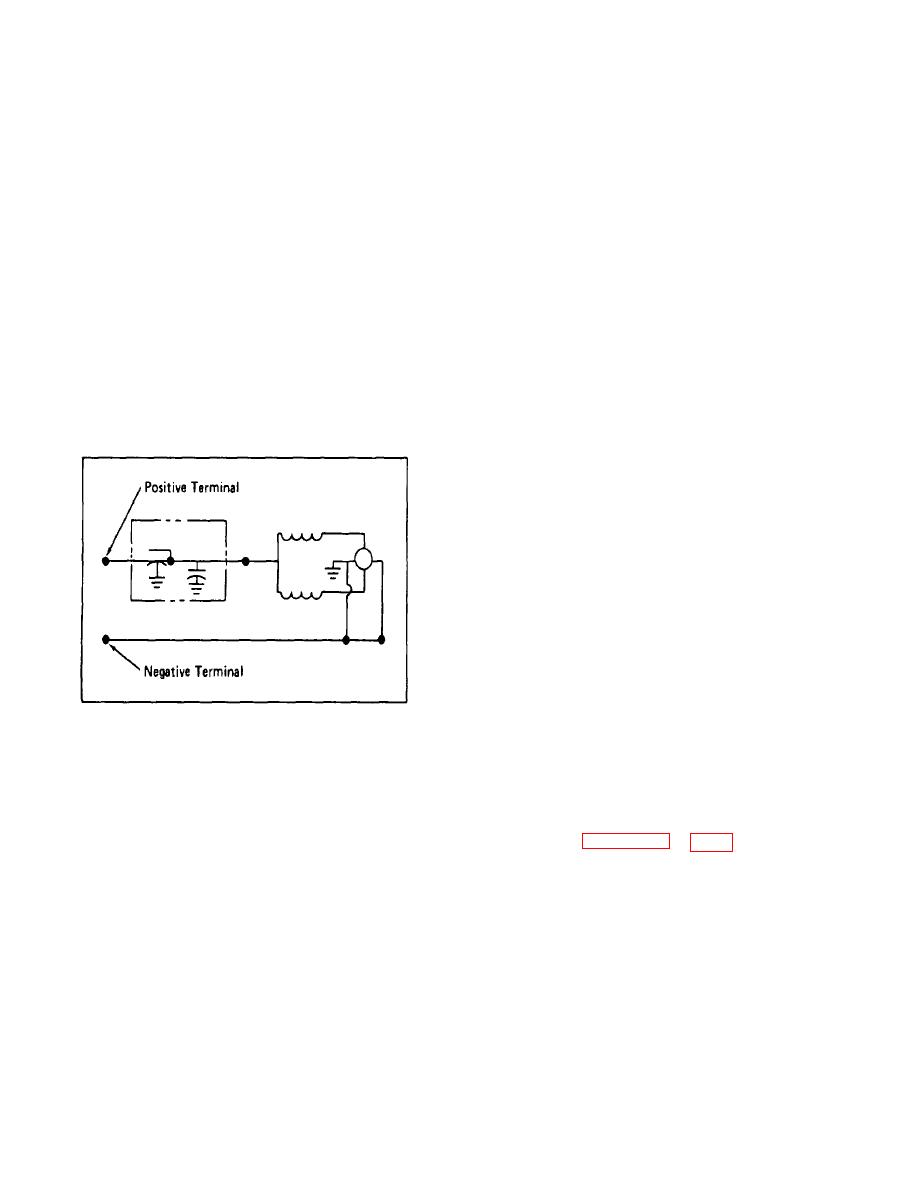

Figure A-2 . Electrical Wiring Schematic

180 across insulator ring (16). These are

negative brush holders.

A-6.

REASSEMBLY.

11. Install two springs (20) on spring holder

A. General.

(19) and insert holder through insulator

ring (16). Install washer (18) and nut (17),

Reassemble the motor (Fig. A) generally in the

reverse order of the index numbers which

springs and spring holders.

represent the order of disassembly.

12. Torque nuts (21) and (17) to 25-29 inch-

1. Assembly of fields into the stator housing

pounds Torque screws (25) to 40-46 inch-

was accomplished during repair and

pounds.

replacement.

13. Align the assembly with one positive

2. Set housing (53) in base (46) and install

brush holder centerline rotator 45

screws (45) torqued to 80 to 100 inch-

clockwise from the scribe mark on the

pounds.

side of end bell (30). Install washers (15)

and screws (14) torqued to 20-25 inch-

3. Install insert (43) if it was removed. Press

pounds.

bearing (44) on armature (42).

14. Install screws (12), washers (13) and

A-6