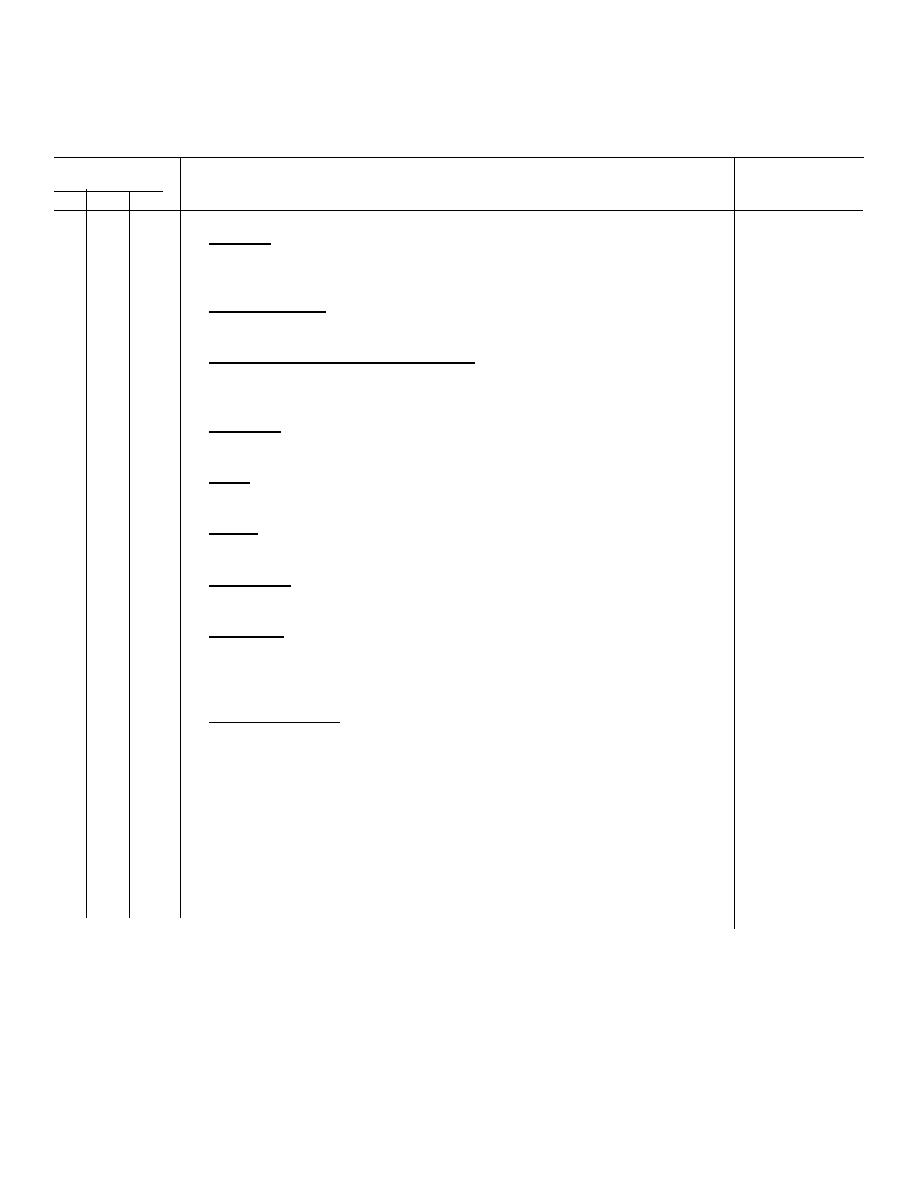

Table C-1. Operator/Crew Preventive Maintenance

checks and Services

B-Before Operation

D- During Operation

A-After Operation

Time required; 1.9

Time required: 0.8

Table 3-2.

Interval and

Work

Sequence no.

Item to be Inspected

Time

B

D

A

Procedure

(M/H)

1

1

Air Hose. Inspect for wear, brittleness, breaks,

0.1

and improper connection. Check for leaks during

operation.

2

Electrical Conduit. Inspect for wear, breaks, and

0.1

improper connections.

3

1

Compressor Crankcase 0il Level Gage. Inspect for

0.1

broken glass. Add oil as required. Refer to

lubrication chart for capacity.

4

Belt Guard. Inspect for dents, breaks, and loose

0.1

mounting.

5

2

V-Belt. Inspect for worn, frayed, or cracked belts

0.1

During operation, check for slipping.

6

Pulley. Inspect for wear, broken edges and loose

0.1

mounting.

7

3

Globe Valve. Inspect for a bent or broken handle

0.1

Check for Improper operation and air leaks.

8

4

2

Drain Cock. Inspect for a bent or broken handle

0.1

Check for Improper operation and air leaks. Be

certain drain cock drains any water from air

receiver.

9

5

3

Air Pressure Gages. Inspect for broken glass and

0.1

loose mounting. Check for improper operation.

10

6

Safety Relief Valve Inspect for a bent valve,

0.1

loose mounting, and loss of ring on end. Check for

improper operation by pulling ring on end of valve.

11

4

Air Intake Muffler Inspect for dents, breaks,

0.1

and loose mounting. Check for dirt and foreign mat-

erial, clogging muffler. Lubricate as required. Refer

to lubrication chart for lubricating instructions.

C-2