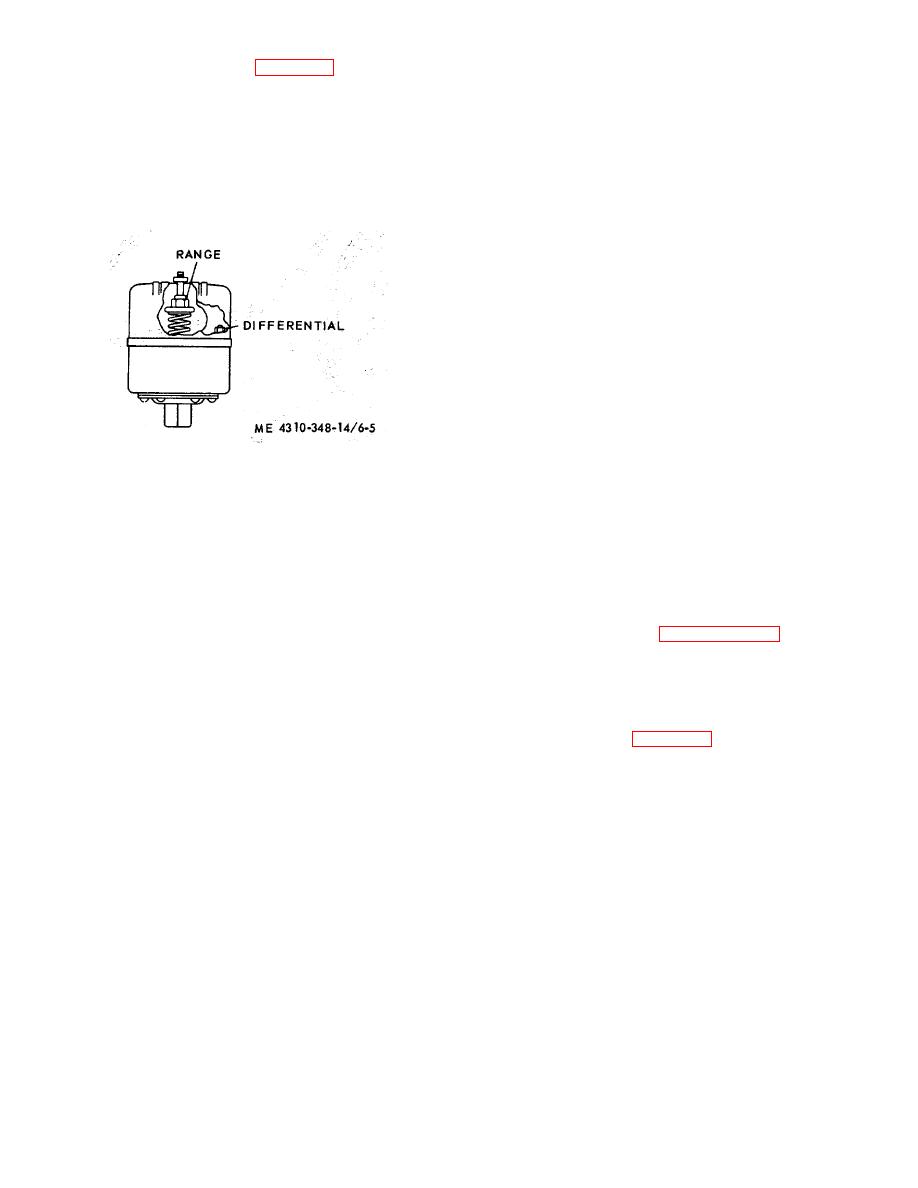

There is interaction between these two adjustments.

b. Installation. Refer to figure 6-4 and reverse the

If the cut-out is increased, so will the differential

removal procedures to install the pressure switch.

increase. Or, if the differential is reduced, the cutout

will be reduced. This factor must be considered, and

c. Adjustment. The pressure switch has a cut-out

compensated for when adjusting.

adjustment and a differential adjustment. The cut- out is

the pressure at which the switch contacts open, and the

(1) Increase the cut-out point by turning the

differential is the span between the cut-in and cut-out

range nut (fig. 6-5) clockwise.

settings.

(2) Decrease the cut-out point by turning the

range nut counterclockwise.

(3) Note the pressure gage readings at which

the motor starts or stops. Re-establish the differential

setting if necessary.

(4) Increase the differential by turning the

differential (fig. 6-5) nut clockwise. Turning the nut

counterclockwise decreases the span.

NOTE

It is advisable to have as wide a

differential as possible to avoid

frequent starting and stopping of the

NOTE

compressor.

Section II. AIR COMPRESSOR

ease in starting, and to minimize wear on bearings and

6-5. General

shaft of the drive motor.

The air compressor is a 2-cylinder, 2-stage air cooled

compressor. It has a capacity of 5 cfm at 610 rpm, and

6-6. Air Compressor

the electric motor drive cuts-in at 175 psi.

The

compressor stops when the air pressure gage indicates

a. Removal Refer to paragraph 4-10 and remove

200 psi, plus or minus 5 psi. The compressed air is

the air compressor.

cooled by a finned inter-cooler tube between the first

stage cylinder and the second stage cylinder. The second

b. Disassembly.

stage compression is cooled by an aftercooler tube on its

way to the air receiver. These tubes remove most of the

heat of compression before the air reaches the receiver.

(1) Refer to figure 6-6 and remove fanwheel,

The compressor is equipped wiih a centrifugal unloader

aftercooler, and the intercooler in numerical sequence.

and pilot valve system, to unload/ internal pressure for

6-7