TM 5-4310-349-14

CHAPTER 3

OPERATOR/CREW MAINTENANCE INSTRUCTIONS

Section I. LUBRICATION INSTRUCTIONS

containers and store in a clean dry place away from

3-1.

General Instructions

external heat. Allow no dust, dirt, or other foreign

a. The motor issued with this air compressor has

material to mix with equipment. Keep all lubrication

been factory lubricated for its lifetime.

equipment clean.

b. Cleaning. Wipe lubricating points free of dirt.

frequently, since excessive oil consumption is the

Clean lubrication points after lubricating to prevent

principal method of determining the compressor's need

accumulation of foreign matter.

for repairs.

c. Service. Service lubrication points at proper

intervals as shown in LO 54810-849-12.

3-2.

Lubrication instructions

a. General.

Keep all lubricants in closed

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Because all required inspections must be made daily, or

more frequently, operator/crew personnel will refer to

their periodic inspection.

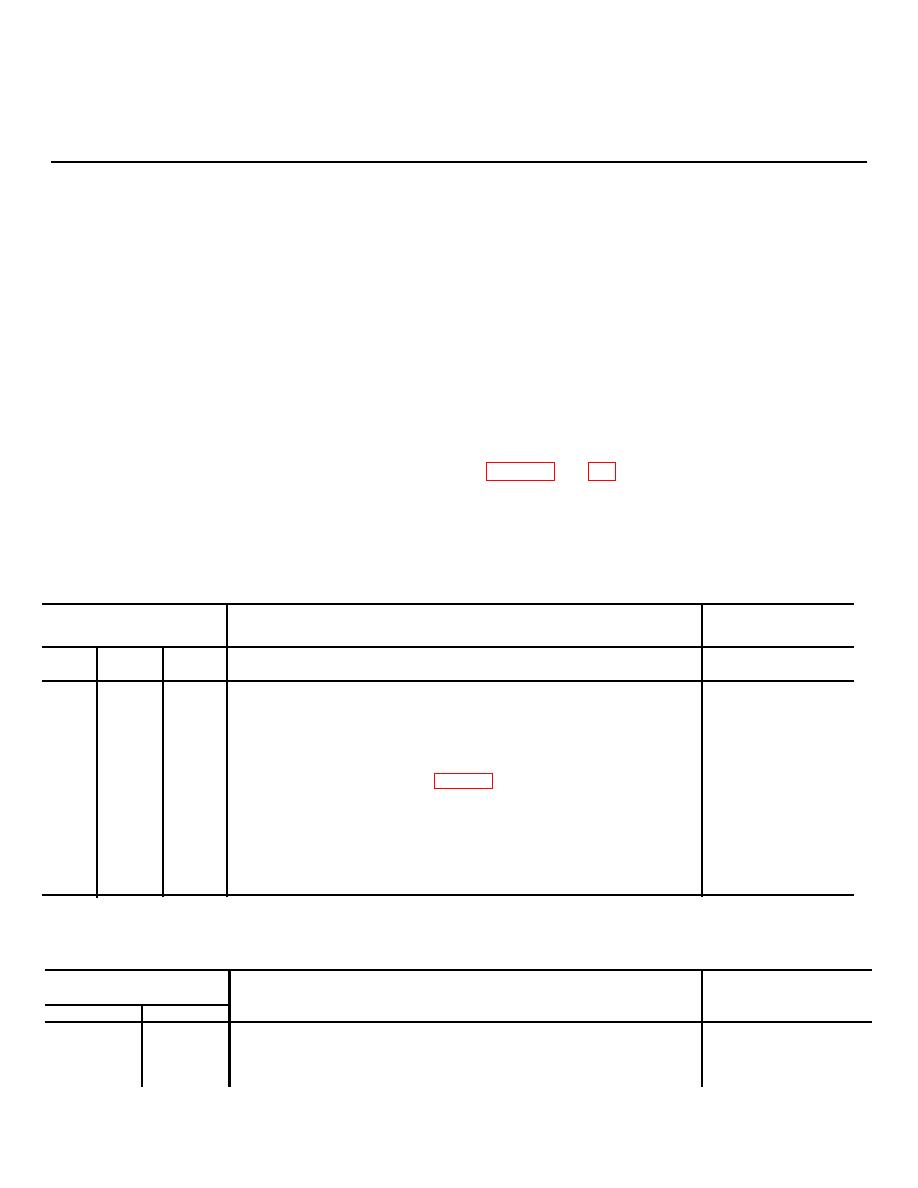

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services

B-Before Operation

D-During Operation

A-After Operation

Time Required:0.1

Time Required:

Item to be Inspected

Work Time

Interval

Procedure

(man-hour)

B

D

A

NOTE

Visually inspect for evidence of lubricant leak

concurrently with daily service checks

1

INSPECT OIL LEVEL IN COMPRESSOR FRAME

Remove fill plug in crankcase (fig. ,1-1), (LO 5-4310-49-12)

1

OBSERVE PRESSURE GAGE OPERATION

Watch pressure gage reading when the motor starts and stops. Motor

should start when gage reads 140 psi. Motor should stop when gage

reads 175 psi. When gage operation is improper, notify organizational

maintenance.

Table 3-2. Operator/Crew Preventive Maintenance Checks and Services

D - Daily

W - Weekly

Time required: 0.2

Time required: 0.4

Interval and

Item to be Inspected procedure

Work time

Sequence No.

(M/H)

D

W

1

CLEANLINESS OF EQUIPMENT

Inspect the exterior of the air compressor. The belt guard, motor, V-belts,

compressor, and the receiver should be clean and free of dust, dirt or oil.

3-1