TM 5-4310-349-14

b. Installation.

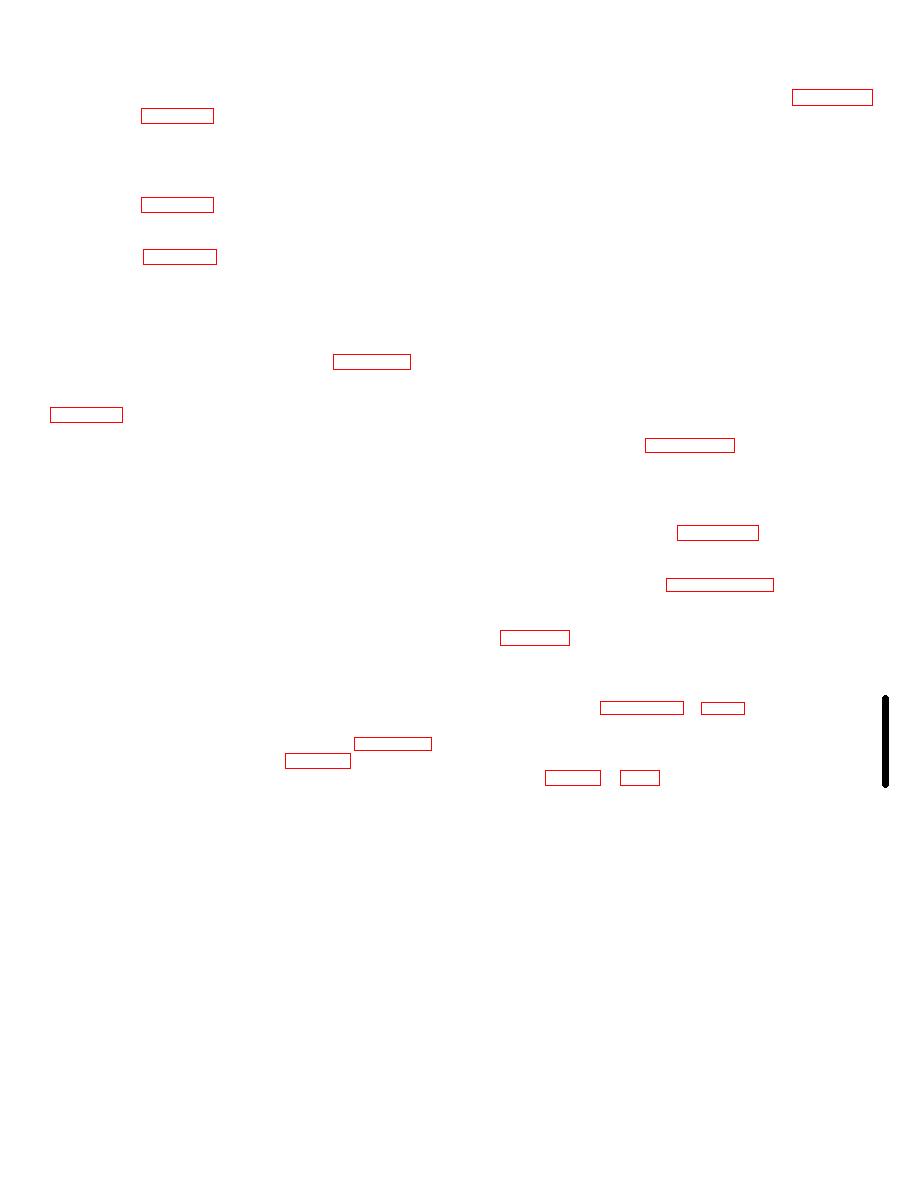

Install the electric motor as

and disassemble release valve assembly as shown.

instructed on figure 4-4.

b. Cleaning, Inspection, and Repair.

4-12.

Compressor Assembly

(1) Clean all parts and wipe dry with a lint

free cloth.

instructed on figure 4-4.

(2) Check the spring (2) for disfiguration or

less of tension. Replace a defective spring.

instructed on figure 4-4.

(3) Check ball (3), body (4), plunger sleeve

4-13.

V-belts

(6), and plunger (7) for excessive wear, burred threads,

and general condition. Replace damaged or defective

a. Removal.

parts as necessary.

(1) Remove V-belt drive guard, figure 4-5.

(4) Replace deteriorated gaskets.

(2) Remove the V-belts as instructed on

c. Reassembly and Installation.

(1) Refer to figure 4-6 and reverse the

b. Cleaning.

disassembly procedures.

(1) Use a cloth dampened in cleaning

4-15.

Air Intake Mufflers

solvent, Fed. Spec. P-D-680, to remove oil and dust

film. If the belts appear to have been saturated, and the

heat has glazed the surfaces of the vee's, proceed as

intake mufflers as shown.

follows:

(2) Use a medium grade of grit paper (not

emery cloth) and rough up the surfaces with strokes of

c. Installation. Reverse removal procedure shown

uneven direction.

in figure 4-5.

(3) Wipe off all grit particles. When surface

4-16.

Air Receiver Repair

has been deglazed, install the belts on pulleys.

c. Installation.

defective components in numerical sequence.

(1) Install V-belts as instructed on figure 4-5,

b. The check valve (5) can be disassembled for

and adjust tension as described (b, para 3-7).

(2) Install V-belt drive guard.

c. Replace defective or damaged components in

reverse order of their removal.

4-14.

Release Valve Assembly Replacement

Change 2 4-7