TM 5-4310-349-14

Section II. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

4-6.

Special Tools and Equipment

4-7.

Maintenance Repair Parts

There are no special tools or equipment required to

Repair parts and equipment are listed and illustrated

perform maintenance on the air compressor.

in Appendix C of this manual.

Section III. LUBRICATION INSTRUCTIONS

Refer to Paragraph 3-2 for lubrication instruction for this air compressor.

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Because all required inspections must be made daily,

personnel will refer to table 4-1, for procedures to be

or more frequently, organizational maintenance

followed during their periodic inspection.

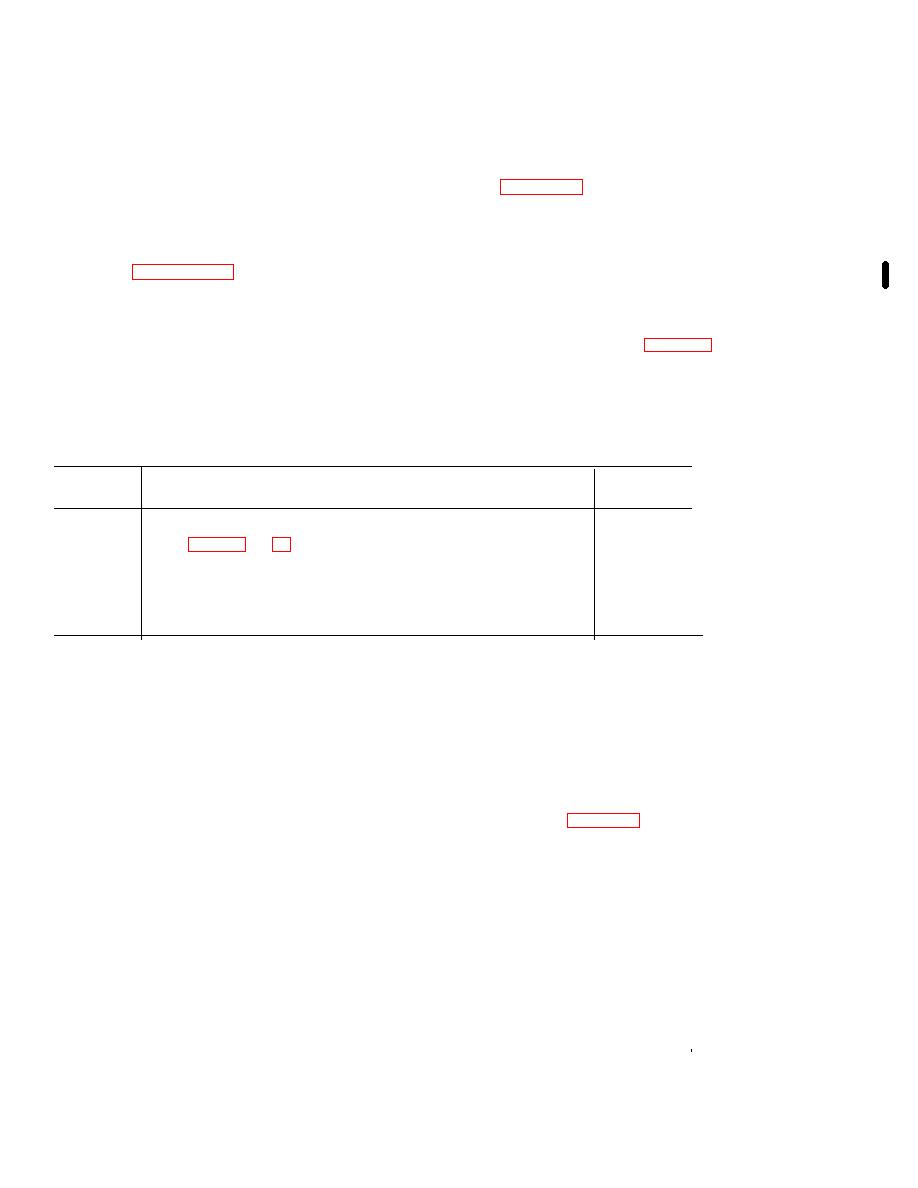

Table 4-1. Organizational Preventive Maintenance

Checks and Services

Q--Quarterly

Total man-hours required: 3.0

Sequence

Item to be inspected

Work time

Number

procedure

(M/H)

NOTE

Use Tables 3-1 and 3-2 for preventive maintenance checks and service,

then return to this Table for expansion of checks and services

1

COMPRESSOR FRAME OIL

Refer to LO 5-10-84912 for type, then drain and change ail.

Check that all capscrew, screws, and bolts are tight

2

CAPSCREWS, SCREWS, AND BOLTS

Check that all capscrews, screws, and bolts are tight.

0.3

Section V. TROUBLESHOOTING

b. This manual cannot list all malfunctions that

4-8.

General

may occur, nor all tests or inspections and corrective

actions. If a malfunction is not listed or is not corrected

a. This

section

contains

troubleshooting

by listed corrective action, notify your supervisor.

information for locating and correcting most of the

trouble that may develop in the air compressor Each

4-9.

Troubleshooting

malfunction for an individual component is followed by a

list of tests or inspections which will help you to

determine probable causes and corrective actions to

Refer to Table 4-2 below for malfunctions, tests, or

take. You should perform the tests/inspections and

inspections, and corrective actions.

corrective actions in the order listed.

Change 2 4-5