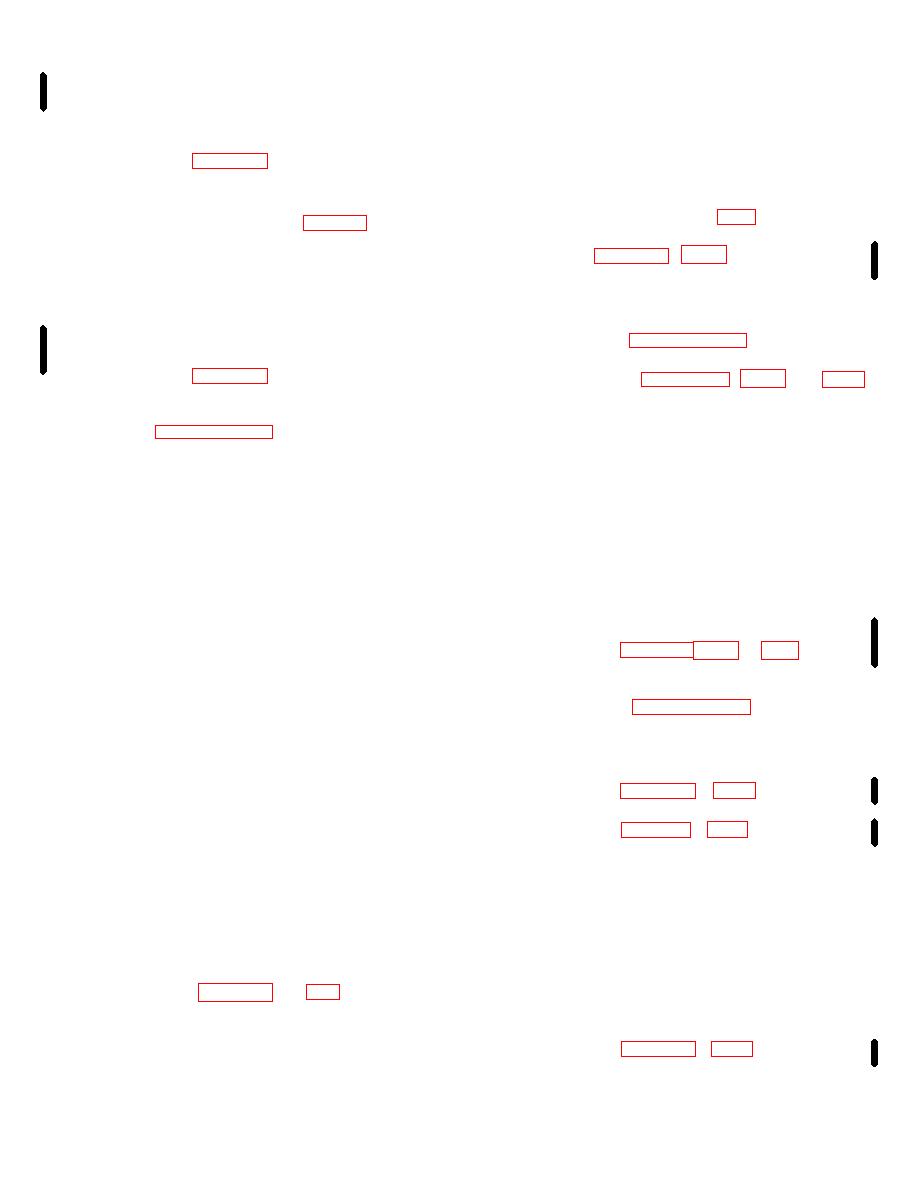

TM 5-4310-349-14

(b) Press bearing cup in the unloader

5-5.

Crankshaft and Crankcase (Model HR108M-1

housing.

and Model 20-277M)

(c) Install new gasket on the unloader

a. Removal and Disassembly.

housing.

(1) Refer to figure 5-1 and remove the unloader

c.1. Reassembling and Installation (Model HR10-

assembly.

8M4)

(2) Remove the handhole plate and flywheel.

(1) Refer to figures 5-1.1 and 5-3.1 reassemble and

(3) Remove bearing caps (fig. 5-3) and push

install crankcase using the above procedures:

connecting rods and pistons up to the top of the cylinder

(2) Refer to figure 5-4 or 5-4.1, depending on model

bore.

Remove the capscrews that secure unloader

of compressor, and disassemble electric motor.

housing to crankcase.

5-6.

Electric Motor

(4) Drive the crankshaft, bearings, and unloader

housing from the crankcase.

a. Removal and Disassembly.

a.1. Removal and Disassembly (Model HR10-

(1) Refer to paragraph 4-11 and remove the

8M4)

electric motor.

(1) Refer to figure 5-1 and remove the unloader

(2) Refer to figure 5-4, 5-4.1, or 5-4.2,

assembly.

depending on model of compressor, reversing the

procedures and reassemble the electric motor as shown.

(2) Remove piston and connecting rod assemblies

as described in paragraph 5-4.1.

b. Cleaning Inspection and Repair.

(3) Remove the capscrews that secure unloader

(1) Clean all parts except rotor, bearings, and

housing to crankcase.

stator in cleaning solvent and wipe dry with a lint free

cloth.

(4) Drive the crankshaft, bearings, and unloader

housing from the crankcase.

(2) Use compressed air to clean dust and dirt off

rotor, bearings, and stator, then wipe with a cloth

CAUTION

dampened in cleaning solvent.

Before driving the crankshaft from the

(3) Inspect bearings and rotor shaft for

crankcase, be sure the connecting rod

excessive wear, and rough or scored surfaces. Replace

journals are in an upright position.

defective bearings. Replace a defective rotor shaft.

(5) Using suitable puller remove the unloader

c. Reassembly and Installation.

housing and bearing from the shaft.

(1) Refer to figure 5-4, 5-4.1, or 5-4.2 reversing

(6) Remove the oil seal from the crankcase.

the procedures and reassemble the electric motor as

NOTE

shown.

Do not remove the oil level gage from

(2) Refer to paragraph 4-11 and install the

the crankcase unless the gage is

electric motor.

leaking or defective.

5-7.

Magnetic Starter

b. Cleaning, Inspection, and Repair.

a. Removal and Disassembly.

(1) Clean all parts in cleaning solvent and dry

(1) Refer to figure 5-5 or 5-5.1 and remove the

thoroughly.

magnetic starter as shown.

(2) Inspect the crankshaft for cracks, scores, and

(2) Refer to figure 5-6 or 5-6.1 and disassemble

distortion. Measure the crankshaft journals for wear. If

starter as shown.

the connecting rod journals measure 0.0005 inch out-of-

b. Cleaning, Inspection and Repair.

round, replace the crankshaft.

(3) Inspect the crankshaft bearings for rough,

(1) Use compressed air and remove all dust or

pitted, or scored rollers. Replace a defective bearing.

dirt from magnetic starter components.

(4) Inspect the crankcase for cracks, breaks, or

(2) Check continuity of heater coil, operating

other defects. Replace the crankcase if defective.

coil, relay overload contact carrier and interlock

assembly. Replace defective parts.

c. Reassembly and Installation.

(3) Check on-off switch continuity and stem

(1) Refer to figures 5-1 and 5-3 reassemble and

action. Replace a defective on-off switch.

install crankshaft in crankcase using the following

c. Reassembly and installation.

procedures:

(a) Always install new oil seal in

(1) Refer to figure 5-6 or 5-6.1 and reassemble

starter.

crankcase.

Change 2 5-5