TM 5-4310-356-14

LUBRICATION ORDER

LO5-4310-356-12

COMPRESSOR, AIR, TANK MOUNTED, ELECTRIC MOTOR DRIVEN,

5 CFM AT 175 PSI CHAMPION MODEL NO. HR2-6M-1

Clean fittings before lubricating. Relubricate all areas

Intervals and related task-hour times are based on

exposed to water after amphibious operation.

normal hours of operation. The task-hour time specified

Lubricate points indicated by dotted arrow shaft on both

is the time you need to do all the services prescribed for

sides of equipment. Clean parts with SOLVENT, dry

a particular interval.

Change the interval if your

cleaning, or with OIL, fuel, diesel.

Dry before

lubricants are contaminated or if you are operating the

lubricating. Drain crankcases when HOT. Fill and

equipment under adverse operating conditions,

check level.

The lowest level of maintenance

including longer-than-usual operating hours.

authorized to lubricate a point is indicated by one of the

following: (c) operator/crew, or (O) organizational

You may extend the interval during periods of low

maintenance.

activity, but you must take adequate preservation

You can improve this publication by calling attention to

precautions.

errors and by recommending improvements and by

stating your reasons for the recommendations. Your

letter or DA Form 2028 (Recommended Changes to

Publications and Forms) should be mailed directly to

Commander, U.S. Army Troop Support and Aviation

Material Readiness Command, ATTN: DRSTS-MTPS,

4300 Goodfellow Blvd., St. Louis, MO 63120. A reply

will be furnished directly to you.

*The time specified is the time required to perform all

services at the particular interval.

LUBRICANT INTERVAL

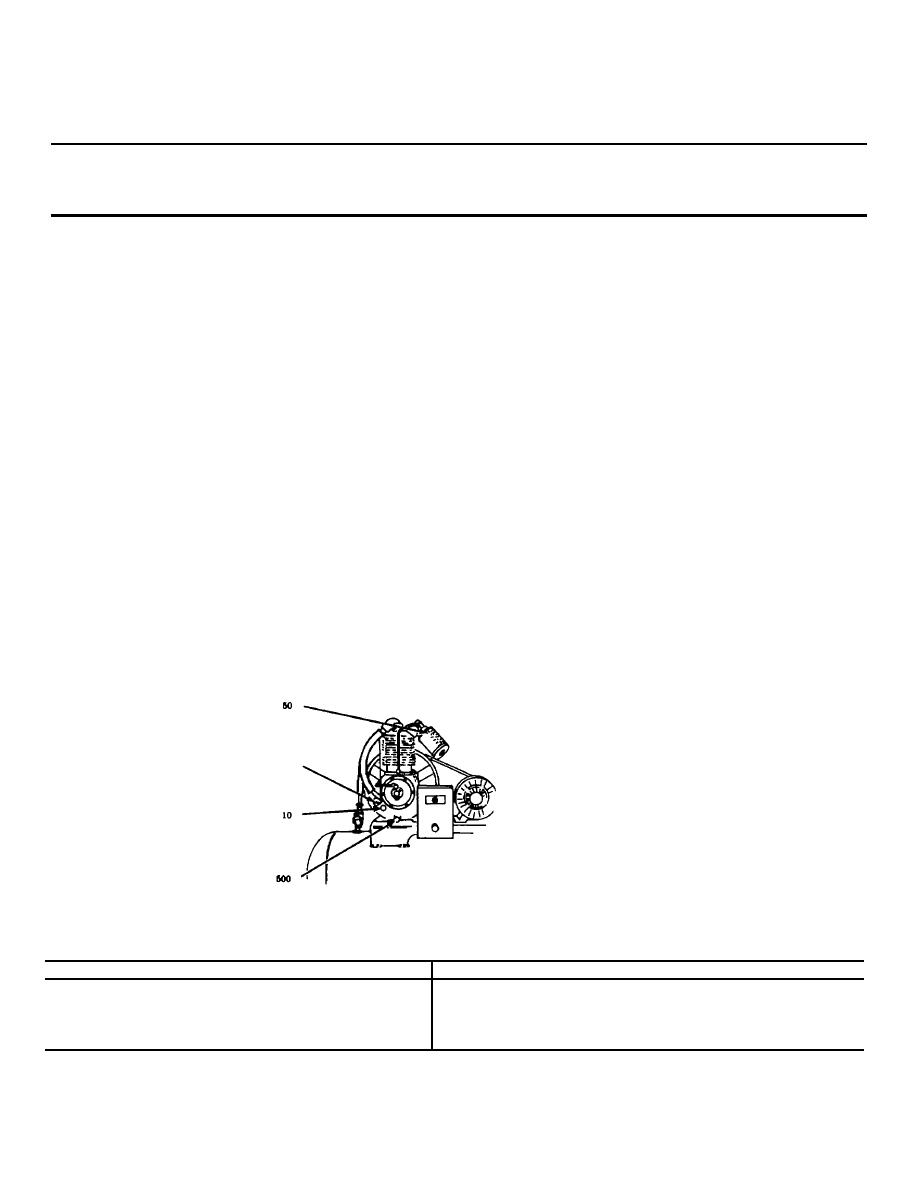

Air Intake Muffler

Disassemble, Clean

and Reassemble

Oil Filler Cap

OE/HDO

(See Key)

Oil level Sight

Gage (Check Level

and add oil

to full mark)

Oil Drain Cap

(Drain and Refill)

(See Note 1)

TOTAL TASK HOURS

*TOTAL TASK HOURS

INTERVAL

TASK-HOURS

INTERVAL

TASK-HOURS

10

0.1

50

0.25

500

0.5

Figure 3-1. Lubrication Order (Sheet 1 of 2).

3-2