TM 5-4310-360-14

1-12. Direct and General Support

Maintenance Data - continued.

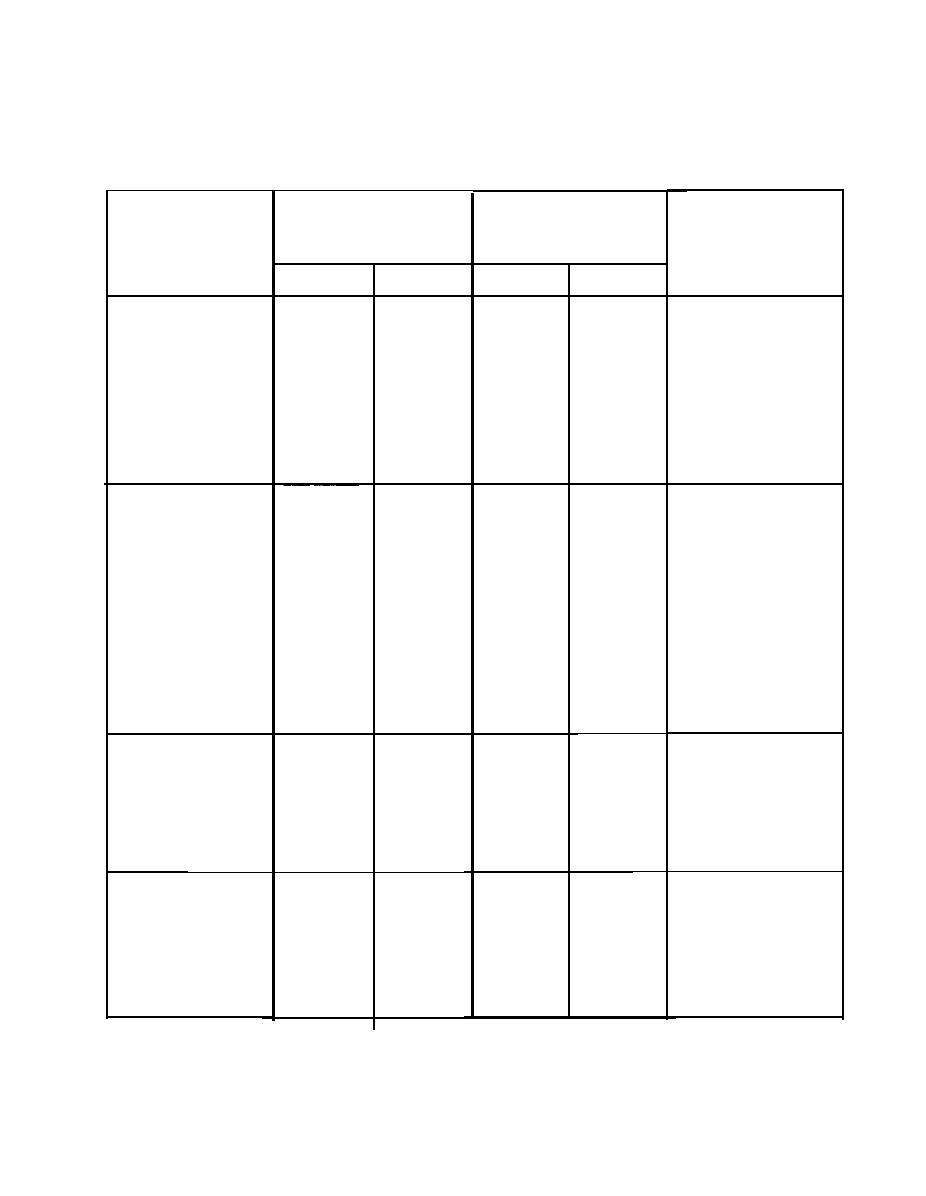

Table 1-1. Compressor Repair and Replacement Standards

Mfr's Dimensions and

Maximum Allowable

Tolerances in

Wear and Clearance

Desired Clearance

Inches (cm)

Components

in Inches (cm)

in Inches (cm)

Maximum

Minimun

Minimum

Maximum

Cylinders:

Bore, low pressure

3 .0000

3.0010

3.0030

0.0060

0.0045

(7.6200)

(7.6230)

(0.0150)

(0.0114)

(7.6280)

1.5000

Bore, high pressure

0.0022

1.5008

1.5028

0.0009

(3.8100)

(3.8 120)

(0.0056)

(0.0023)

(3.8171)

Bores, out-of-round

0.0010

(0.0030)

Crankshatt:

Journal (rod) size

0.8746

0.8736

0.0019

0.0011

0.8750

(2.2215)

(2.2189)

(0.0048)

(2.2225)

(0.0028)

0.0010

Taper

(0.0030)

0.0010

Out of round

(0.003)

End play

0.0020

0.0020

0.0000

(0.0050)

(0.0050)

Piston to Cylinder:

Low, pressure, skirt

0.0060

2.9955

2.9950

2.9930

0.0045

(0.0150)

(7.6086)

(7.6073)

(7.6020)

(0.0114)

High pressure, skirt

0.0022

1.4991

1.4966

0.0009

1.4986

(3.8077)

(3.8014)

(0.0056)

(0.0023)

(3.8064)

-___-_-

Piston Ring Gap:

Low pressure

0.0250

0.0100

0.0150

0.0100

0.0150

(0.0254)

(0.0635)

(0.0381)

(0.0381)

(0.0254)

0.0070

High pressure

0.0220

0.0120

0.0120

0.0070

(0.0559)

(0.0305)

(0.0180)

(0.0305)

(0.0180)

1-5