TM 5-4310-370-14

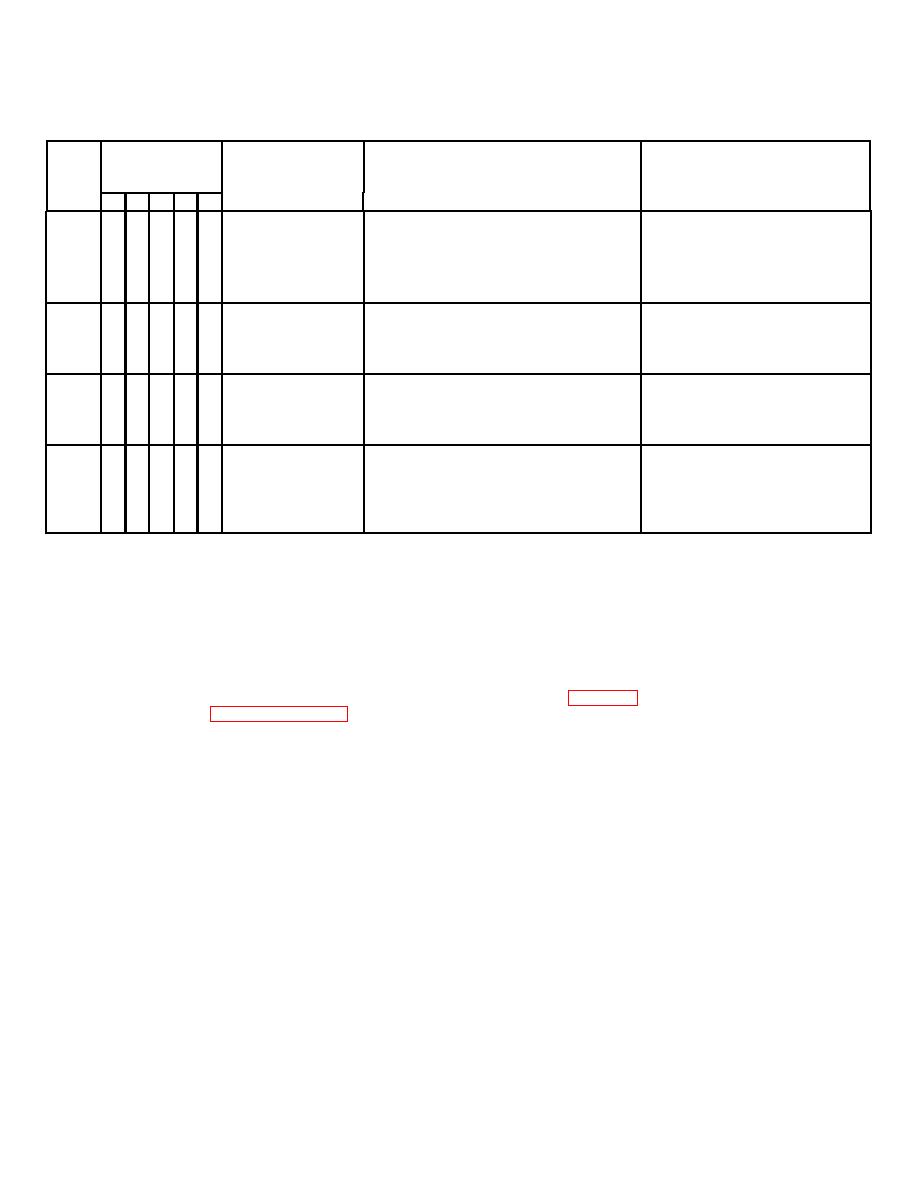

TABLE 2-1. OPERATOR/CREW PREVENTIVE CHECKS AND SERVICES (Cont'd)

INTERVAL

Procedures: Check for and

For readiness reporting

Item

Item to be

have repaired or adjusted,

equipment is not ready/

BDAWM

Inspected

as necessary

available if:

7

Inflator

Check for damage to

If damage is such

Gage

inflator gage.

that it interferes

with the proper

working or measuring

of air.

8

Pressure

Check air pressure.

Pressure exceeds

Gage

Pressure should not

195 PSI (1350 KPa).

exceed 195 PSI (1350 KPa).

9

Air

Check to make sure air

Air receiver drain

Receiver

receiver drain is tightly

is missing.

Drain

closed.

10

Visible

Check to see that oil has

Oil is below proper

Sight Oil

been filled to level shown

level.

Level Gage

on visible sight oil level

gage.

Section III. OPERATION UNDER USUAL CONDITIONS

2-4.

INSPECTION AND SERVICING PRIOR TO OPERATION.

a. Inspection. You should inspect the entire compressor unit for signs of damage, missing or loose hardware, or any

faults that may have occurred during shipment. Report all faults to your supervisor.

b. Servicing. Perform all the preventive maintenance services listed in Table 2-1 and fill compressor pump with oil

as described in Chapter 3, Section I.

c. Check oil level in compressor pump at visible sight oil level gage to make sure compressor pump will have proper

lubrication during operation.

d. Test all inflator gage hose connections to prevent air leaks during operation.

e. Check all pipe connections by twisting and shaking with hands to check for any looseness which could cause air

leaks.

f. Check for any loose screws, nuts, or bolts, as they may present hazards during operation.

2-4