TM 5-4310-370-14

b. This manual cannot list all possible items to be checked. If any other item appears to be in a not ready condition,

refer same to next higher level of maintenance (see APPENDIX B) for servicing.

c. Table 2-1 lists the common items and checks you will need to operate compressor unit. You should perform

these checks and/or services in the order listed.

WARNING

Before you use this table, be sure that unit has been disconnected from main

power supply, to avoid personal injury.

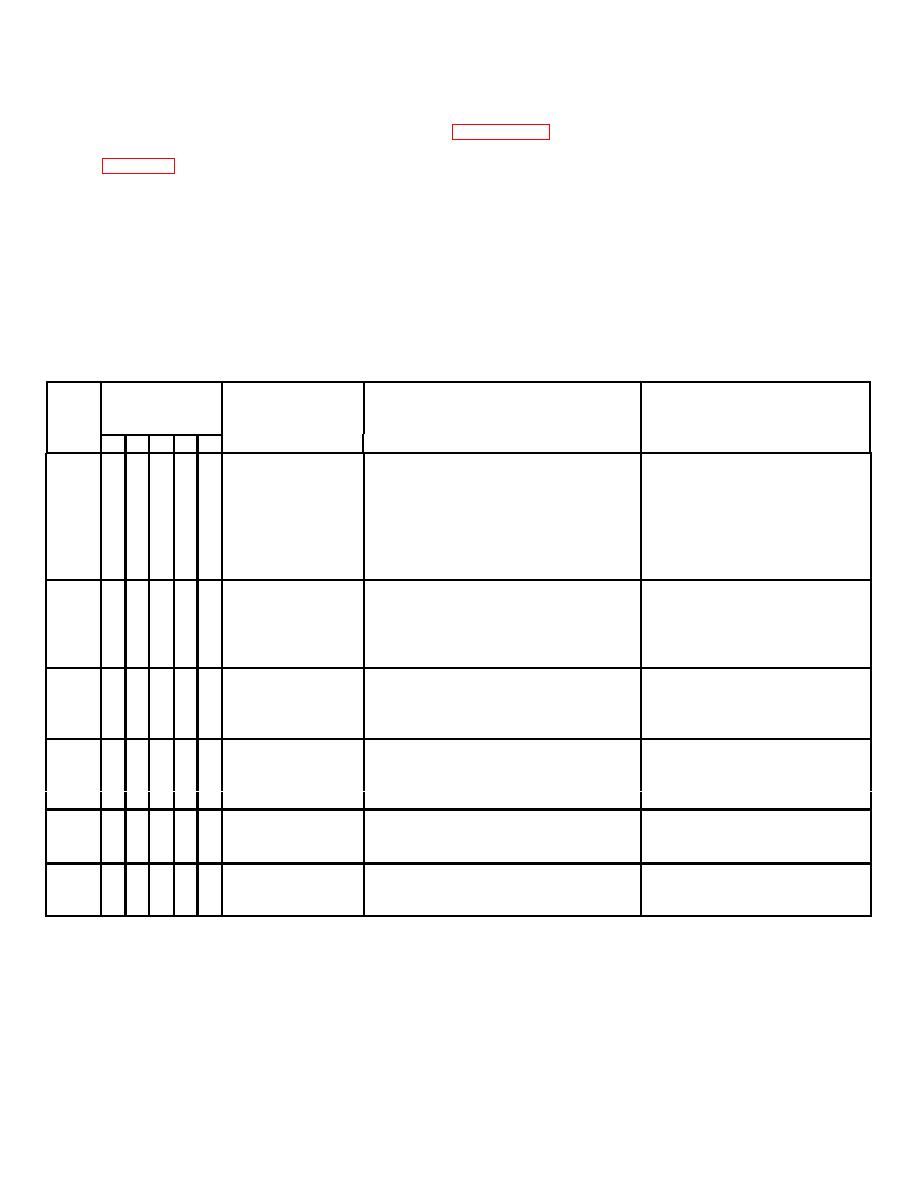

TABLE 2-1. OPERATOR/CREW PREVENTIVE CHECKS AND SERVICES

B-Before

D-During

A-After

W-Weekly

M-Monthly

INTERVAL

Procedures: Check for and

For readiness reporting

Item

Item to be

have repaired or adjusted,

equipment is not ready/

BDAWM

Inspected

as necessary

available if:

1

V Belts

There should be no more

than 1/2" of play in the

belts. To tighten, loosen

four (4) motor mount nuts

and slide motor back until

belts are taut. Tighten

the (4) mounting bolts.

2

Starter

Check for any loose wires

Check finds any loose

Switch

or nuts and bolts.

hardware or wires.

Check to see if switch is

loose.

3

Check for any loose con-

Check finds any loose

Pump

nections or nuts and

connections.

bolts.

4

Air

Check for any damage to

If any damage found

Receiver

Air Receiver or its com-

creates an air leak.

ponents.

5

Globe

Check to see that

Valve

valve turns freely.

6

Inflator

Check for air leaks in

Large air leak is

Gage Hose

hose or its connections.

found.

2-3