TM 5-4310-373-14

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

4-1.

CHAPTER OVERVIEW. This chapter contains maintenance procedures for organizational maintenance personnel.

Section I. REPAIR PARTS, SPECIAL TOOLS, TMDE AND SUPPORT EQUIPMENT

4-2.

COMMON TOOLS AND EQUIPMENT. For repair of the compressor unit you will need the following common tools:

National/NATO Stock Number

Nomenclature

Tool Kit, General Mechanic, Automotive

Shop Set, Automotive Repair, Field

Maintenance, Basic

Shop Set, Machine: Field Maintenance,

Heavy

Shop Equipment, Automotive Maintenance

and Repair: Organization, Common NO. 1

4-3.

SPECIAL TOOLS. Not applicable.

parts are listed and illustrated in the repair parts and special

tools list covering organizational DS and GS maintenance

for this equipment (TM 5-4310-373-24P).

4-4.

SPARES AND REPAlR PARTS. Spares and repair

Section II. SERVICE UPON RECEIPT

4-6.

4 - 5 . SITE AND SHELTER REQUIREMENTS. The com-

SERVICE UPON RECEIPT.

pressor unit was designed for permanent installation in a

WARNING

sheltered environment. Protect the compressor from water,

excessive dirt and corrosive atmospheres. Install the com-

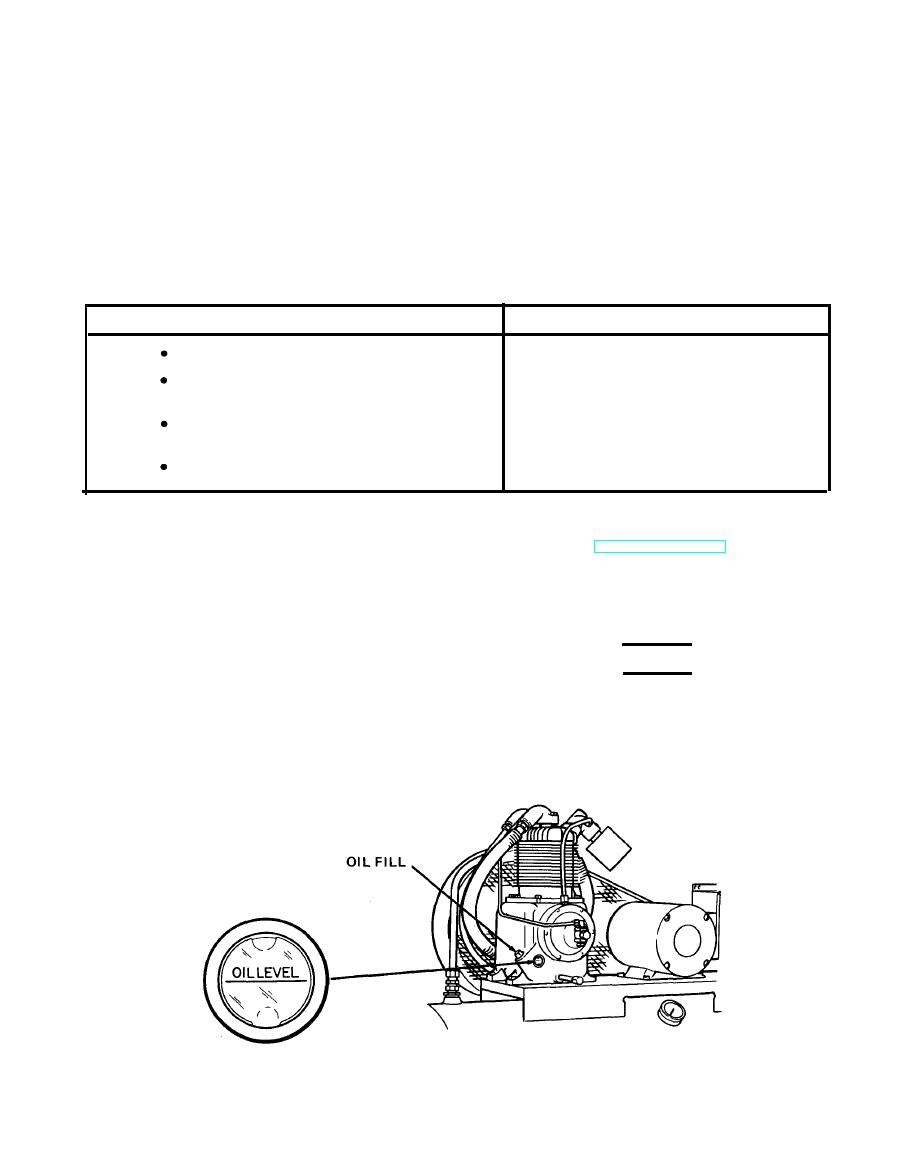

The compressor is shipped without oil in the

pressor in an area that receives adequate ventilation to pre-

vent overheating. Locate the compressor away from

crankcase. Running compressor without oil

is dangerous to personnel and property.

work areas and areas frequently traveled, preferably

outside of the maintenance building. A special noise

Before start-up, fill the crankcase with 2 quarts (1.9 liter)

reduction enclosure may be necessary.

of oil or up to the oil level mark an the level gage.

Figure 4-1. Oil fill, and oil level