TM 5-4310-382-13

LUBRICATION TASK

INTERVAL

LUBRICANT

CAPACITY

After first

Above 32F

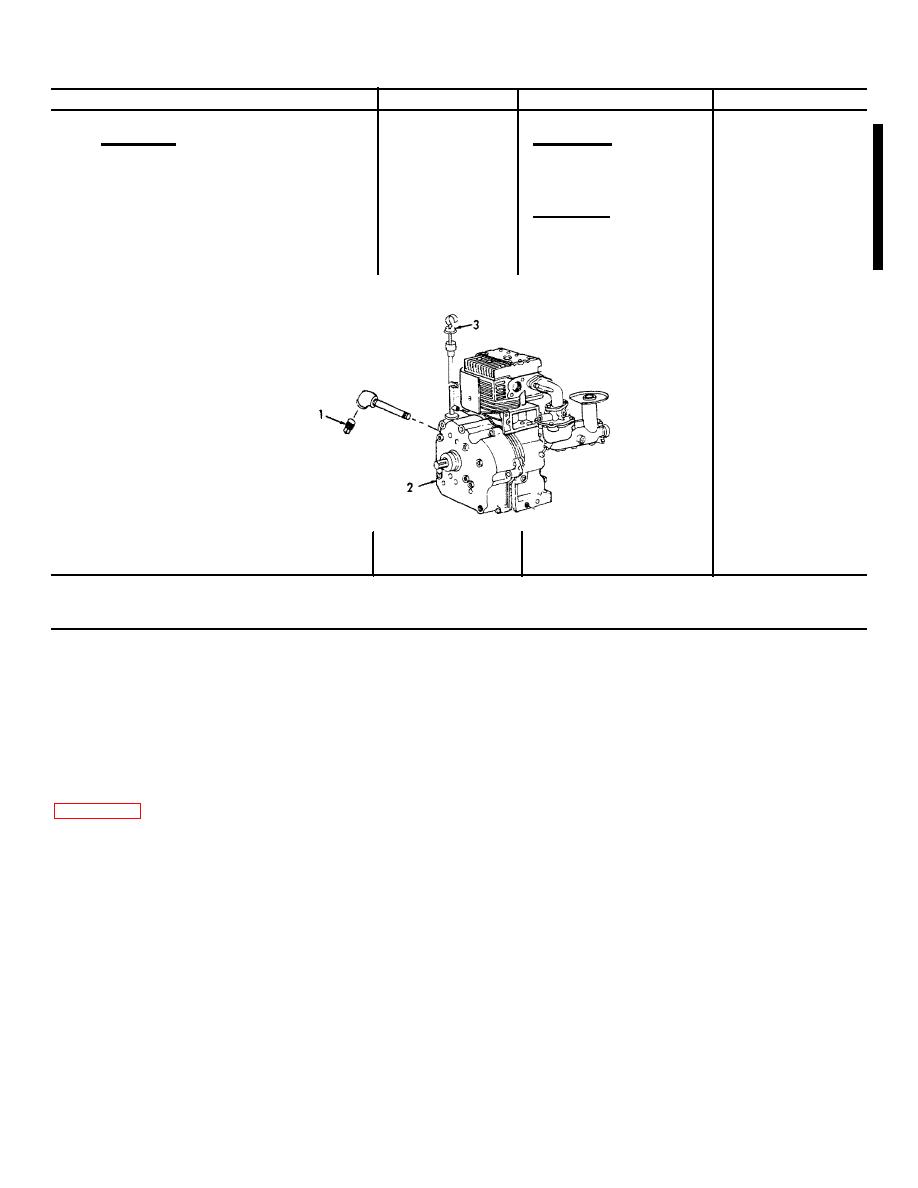

b. Oil Change.

3 pints

(0C) Operation:

While engine is warm, remove oil drain

5 hours of

(1.4 liters)

plug (1) and allow all oil to drain from

operation.

SAE 10W30. Grades

Then after

engine (2) into any suitable container.

SC, SD, or SE

Below 32F

Replace oil drain plug. Remove oil dip-

every 25

(0C) Operation:

stick (3) and fill engine with new oil. Per-

hours of

form oil level check in 2a above.

operation.

SAE 5W-30, Grades

SC, SD, or SE

Section II. REPAIR PARTS, SPECIAL TOOLS, TEST, MEASUREMENT,

AND DIAGNOSTIC EQUIPMENT (TMDE), AND SUPPORT EQUIPMENT

3-3. COMMON TOOLS AND EQUIPMENT. For authorized common tools and equipment refer to the Modified Table of

Organization and Equipment (MTOE) applicable to your unit.

3-4. SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT. Refer to TM 5-4310-382-23P, Unit and Intermediate

Direct Support Maintenance Repair Parts and Special Tools List (RPSTL). Refer to Maintenance Allocation Chart

(Appendix B) for maintenance tasks allocated to unit level. There are three special tools required for maintenance of the

engine on this air compressor unit: puller, mechanical (NSN 5120-00-116-7599); wrench, starter (NSN

5120-00-861-0787); and holder, flywheel (NSN 5120-00-861-5738).

Change 1 3-3