TM 5-4310-386-14

(4)

Inspect cylinder walls for cracks, scoring or damage. Replace if cracked, scored or damaged.

(5)

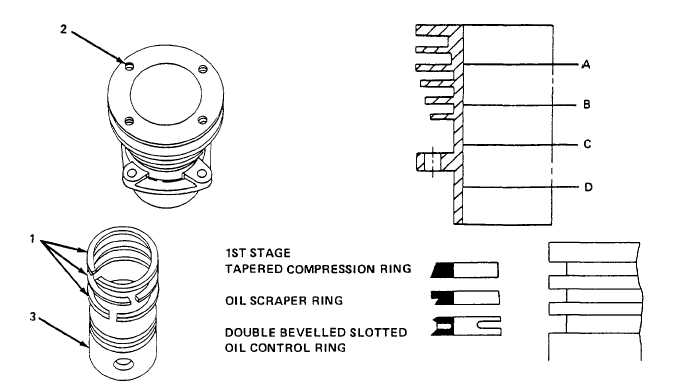

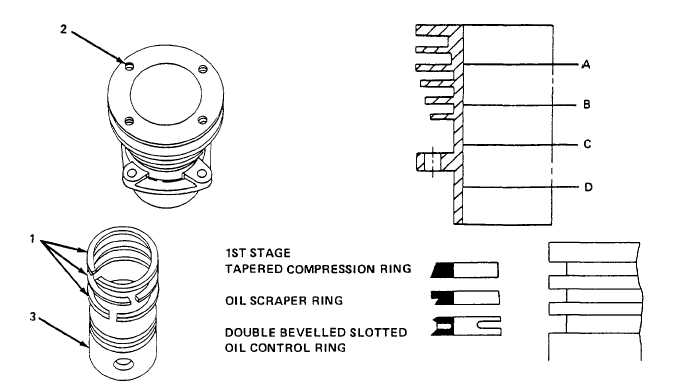

Inspect piston rings (1) for cracks, or excessive wear. Replace if cracked or worn excessively.

NOTE

Maximum wear limit of cylinder diameter is 5.123 inches (130.3 mm).

(6)

Using micrometer, measure cylinder diameter in four places A, B, C and D.

(7)

Place each piston ring in cylinder and measure piston ring gap with feeler gage. Gap must be between

0.0256 to 0.0315 (0.65 to 0.80 mm).

(8)

Install three piston rings (1) on piston (2).

(9)

Measure piston ring clearance in the groove. The clearance should be between 0.00196 to 0.00393

inches

(0.05 to 0.1 mm).

(10) Install 1st stage cylinder and piston (para. a. above).

Figure 6-2. 1st Stage Cylinder and Piston, Repair.

FOLLOW-ON MAINTENANCE

Install 1st stage compressor valve head assembly (para. 5-21).

6-9