TM 5-4310-393-14

b.

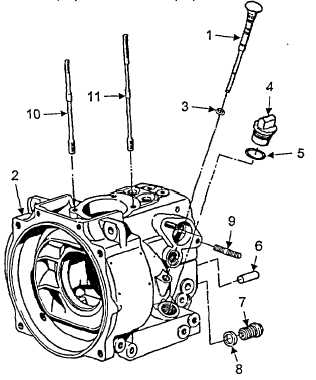

Inspect crankcase for any cracks, discoloration, distortion, rust, corrosion, or other damage. If crankcase is

cracked, distorted, overheated, seriously rusted or corroded on machined surfaces, or exhibits, other serious damage,

replace crankcase

c.

Inspect two studs (Figure 5-52, Item 9), two studs (10), and two studs (11) for thread damage or cracking If

damaged, replace studs

B.

Install.

1.

Installing the Crankcase.

a.

Lubricate gasket (Figure 5-52, Item 8) with

lubricating oil and install on oil drain plug (7) Install oil

drain plug.

b.

Install cylinder pin (6) c. If damaged,

remove two studs (10) and two studs (11) and install new

studs.

d.

If damaged, remove two studs (9) and

install new studs

e.

Lubricate O-ring (5) with lubricating oil and

install on oil filer cap (4). Install oil filler cap.

f.

Lubricate O-ring (3) with lubricating oil and

install on dipstick (1) Install oil dipstick in crankcase

FIGURE 5-52. CRANKCASE

5-7. INSTRUMENTS

GAUGES.

This task covers: A. Calibrate

Tools

Materials/Parts:

Test Stand

Equipment Conditions:

Standard Certified Gauges

A.

Calibrate.

1.

Calibrating the Instruments Gauges.

a.

Using a suitable test stand, compare system gauges against certified gauges of equal service and pressure

range Adjust system gauges as necessary.

5-51