TM 5-4310-393-14

CHAPTER 3

OPERATOR MAINTENANCE INSTRUCTIONS

Page

Section I

Lubrication Instructions ................................................................................................. 3-1

Section II

Service Upon Receipt of Material ................................................................................... 3-7

Section III

Troubleshooting Procedures .......................................................................................... 3-9

Section IV

Operator Maintenance Procedures................................................................................ 3-14

Section I. LUBRICATION INSTRUCTIONS

Paragraph

Page

3-1

General ........................................................................................................................ 3-1

3-2

Oil Viscosity ................................................................................................................. 3-1

3-3

Lubrication of Engine ..................................................................................................... 3-1

3-4

Filling/Checking Engine Oil ............................................................................................ 3-2

3-5

Lubrication of Compressor ............................................................................................. 3-3

3-6

Oil Capacities/Specifications .......................................................................................... 3-5

3-7

Maintenance on a New Engine and Compressor.............................................................. 3-5

3-1. GENERAL.

The objective of this section is to present the operator with engine and compressor lubrication instructions Proper

lubrication is essential to operating life of any machine Always check oil levels of both the engine and compressor before

starting either unit.

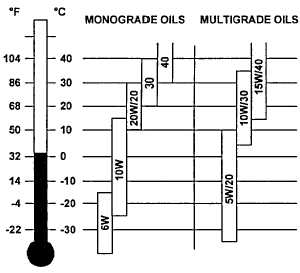

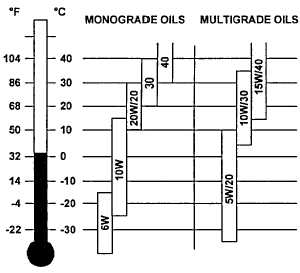

3-2. OIL VISCOSITY.

The viscosity of oil is greatly influenced by ambient

temperatures at the site of operation. Figure 3-1 shows

the viscosity of oil recommended for use in the model

CAPITANO-PD When ambient temperatures fall below

the limit of the oil selected, the starting performance of

the compressor unit will be affected, but no equipment

damage will be caused. Since a too viscous oil can

cause starting difficulties, the choice of viscosity grades

during winter operation should be governed by the

ambient temperature prevailing at the time of engine

starting.

Oil

changes

resulting

from

ambient

temperature

changes

can

be

avoided

by

using

multigrade oils All viscosities are subject to oil change

intervals recommended in Table 2-2.

3-3. LUBRICATION OF ENGINE.

The

engine

is

splash

lubricated.

A

scooper,

incorporated into the connecting rod cap, forces oil

through drilled passages to lubricate the cylinder and

connecting rod bearings.

Figure 3-1. Recommended Viscosity's

3-3.1. ENGINE OIL CHANGE.

The engine oil should be changed regularly according to the PMCS schedule (Table 2-2)

3-1