TM 5-4310-393-14

b.

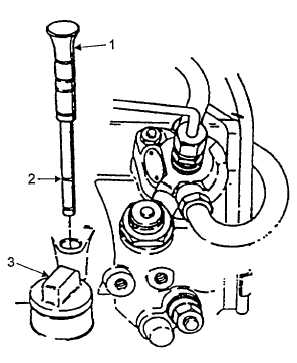

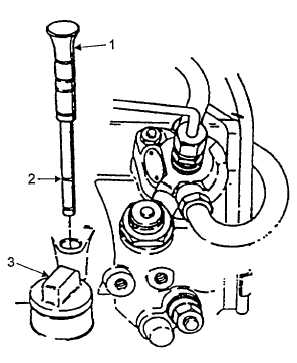

If oil coating is below top mark, remove oil cap (3) and fill with oil of proper viscosity as required.

c.

Select an oil viscosity grade to suit ambient temperature using Figure 3-1.

d.

After adding oil, check oil level again to be sure oil coats dipstick to top mark.

e.

If oil coating extends above the top mark, loosen

drain plug (Figure 1-2, Item 6) and drain enough oil to

lower the oil level to top mark on dipstick then tighten

drain plug securely The drain plug is located in the base

of

the

engine

opposite

the

flywheel,

below

the

crankshaft.

f.

When the procedure is complete, ensure that oil

cap (3) is securely replaced.

3-5. LUBRICATION OF COMPRESSOR.

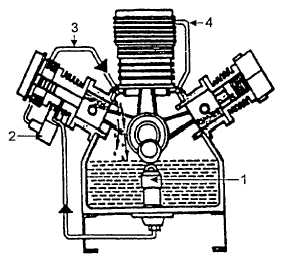

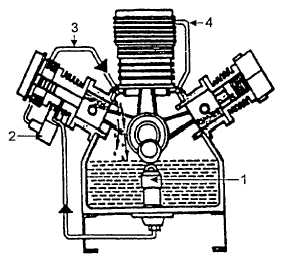

The third stage is force lubricated by a pump (Figure 3-3,

Item 1) operated by a cam of the crankshaft The oil

pressure regulator valve (2) maintains the proper

working pressure Any oil not needed by the third stage is

returned to the crankcase through the feedback tube (3).

Other moving parts of the compressor are lubricated with

oil splashed by the crankshaft Cylinders of the first and

second stages receive additional lubrication from oil

vapors from the crankcase vent feedback line (4).

3-5.1. Operation Under Severe Conditions.

For operation under severe operating conditions such as

continuous running and/or high ambient temperatures,

the use of synthetic compressor oil is recommended.

This oil can also be used under normal conditions. See

paragraph 3-6 for oil specifications

3-5.2. Compressor Oil Level Check.

Check the oil level before starting the compressor. To

check the oil level, vent any residual pressure from the

system by opening and then closing the manual drain

valves/purge valves on the separators and purification

system. Open the filler cap slowly, allowing any residual

pressure to vent from the crankcase Remove the

cap/dipstick from the oil filler neck. Wipe the dipstick

with a lint-free cloth.

FIGURE 3-2. ENGINE OIL FILL

FIGURE 3-3. COMPRESSOR OIL SYSTEM

3-3