TM 5-4310-393-14

4-18.

PRESSURE MAINTAINING VALVE.

This task covers. A Adjust B. Replace

Tools:

Materials/Parts:

Tool Kit, General Mechanic's Set

Non-ionic Detergent, NSN 7930-00-282-9699

Distilled Water, NSN 6810-00-297-9540

Equipment Conditions:

Compressor Operational

Pressure Purged From System

NOTE

The setting of the PMV at the factory

is 2000 psi (138 bar)..

A Adjust

1.

To determine if the Pressure Maintaining

Valve PMV is properly adjusted:

a. Depressurize the final separator and

purification chamber by slowly opening the manual

purge valve.

b.

Close the purge valve and then start

the compressor with the delivery valve open.

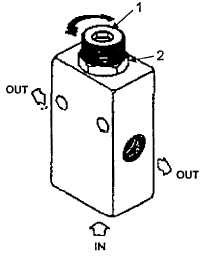

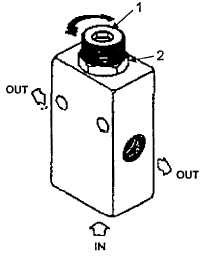

Figure 4-13. PMV

c.

Observe the final pressure and note the pressure at which the PMV opens (air is delivered) If the

pressure is not within 2000 ± 200 psi (138 + 14 bar), readjust the PMV.

d.

To readjust the pressure setting loosen the locking ring (Figure 4-13, Item 2), and using a hex key,

turn adjusting screw (1) clockwise to increase pressure, counter-clockwise to reduce pressure

B.

Replace.

1.

Replacing the PMV.

a.

Open the purge valve and release all air pressure from the system (paragraph 23)

b. Disconnect the air lines from the PMV and install a new unit in its place. Soap test all fittings for leaks

c. Adjust new valve as in steps 1, a through c.

4-19.

INTERSTAGE PRESSURES.

This task covers, A Check B Install C. Test

Tools:

Materials/Parts:

Tool Kit, General Mechanic's Set

Cloth, Lint-free NSN 7920-00-044-9281

Pressure Gauge, Test (P/N 057491

Detergent, Non-ionic NSN 7930- 00-282-9699

Pressure Gauge, Test (P/N 057492)

Water, Distilled NSN 6810-00-297-9540

Equipment Conditions:

Unit Shut Down

4-31