TM 5-4310-452-14

1-15. AIR COMPRESSOR (Con't).

c.

Air flow through the compressor can be regulated from full capacity to zero capacity depending on the demand

placed on the unit. Reduction to zero capacity is done by the air inlet unloader valve. The air inlet unloader valve,

mounted on the rotor housing intake port, controls the capacity of the compressor by a throttling affect, This is done with

a calibrated spring which maintains sufficient pressure on the diaphragm, preventing movement of the air actuating

cylinders to slow the engine to idle and the unloader valve to close off air to the compressor. Discharge air pressure can

be regulated between 75-100 psi (51 7-690 kPa) by adjusting the regulator valve.

d.

Compressor Lubricating Oil.

(1)

The compressor lubricating oil both lubricates and cools. The oil is forced from the oil separator tank, by

system pressure, to the oil cooler. The cooler is located at the compressor end of the unit so that the heat exchanger fan

cools the compressor lubricating oil.

(2)

When the compressor is operating at low capacity, some oil may bypass the cooler through a

thermostatically controlled bypass valve. This valve bypasses varying amounts of oil, depending upon the temperature,

until the oil being circulated reaches a temperature of 185°F (85'C), thereby maintaining a higher average oil temperature

and reducing the possibility of water vapor condensation in the oil.

(3)

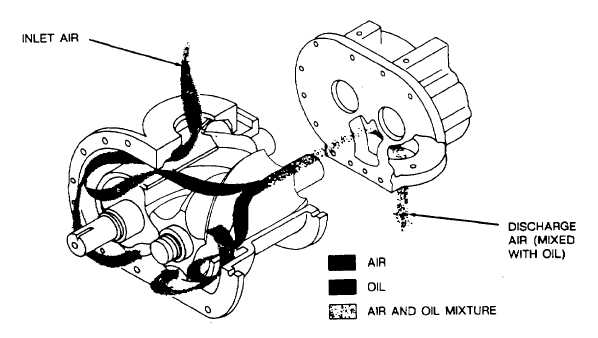

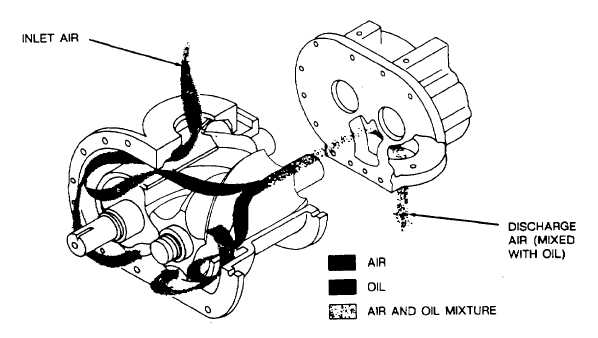

From the oil cooler, the cooled oil is directed through the oil filter, then to the rotor bearings, and, in

metered amounts, directly into the rotor housing. All of the oil introduced mixes with and passes on with the air being

compressed, removing much of the heat of compression,

(4)

On its way to the final discharge connection, the air passes through the piping to the oil separator where

the oil is removed from the air and collects in the oil storage reservoir.

(5)

Primary separation of the oil takes place because of the change in the velocity and direction as the

compressed air enters the oil separator.

(6)

Secondary separation of the oil takes place in the separator element, which is located within the oil

separator. The oil separator consists of a disposable element made of materials designed to remove finely divided oil

droplets which remain in the compressed air as it passes through the oil separator element.

TA505391

1-15