TM 5-4310-452-14

Table 2-1. Operator Preventive Maintenance Checks and Services (PMCS) (Con't).

B-Before

D-During

A-After

W-Weekly

Interval

ITEM TO BE INSPECTED

Equipment is

Item

PROCEDURE: Check for and have repaired

Not Ready

No.

B

D

A

W

filled or adjusted as needed

Available If:

10

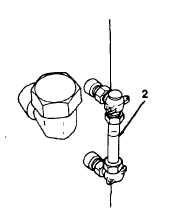

COMPRESSOR OIL LEVEL

WARNING

Compressor lubrication/cooling system is

under pressure. DO NOT remove drain plug

or filler plug from compressor lubricating

cooling system while under pressure or Inju-

ry to personnel may result. First open manu-

al blowdown valve as a safety precaution.

•

•

Check compressor oil level on sight tube (2). Oil

No oil is present in sight tube.

must be present in sight tube when unit is running. If

oil is not present, notify your supervisor.

11

DRIVE BELTS

NOTE

If unit Is new or engine has been overhauled,

unit should be shut down after 20 minutes of

operation and a belt adjustment check

should be performed by organizational main-

tenance.

a. Visually check for broken or missing belts.

Belts are broken or missing.

b. Press down on belts with your thumb and mea-

sure the deflection of belts with rule. If belts de-

flect more than 0.4-0.6 in. (10-15 mm), or are

cracked or deteriorated, notify your supervisor.

TA60539

2-11