TM 5-4310-452-14

Table 2-1. Operator Preventive Maintenance Checks and Services (PMCS) (Con't).

B-Before

D-During

A-After

W-Weekly

Interval

ITEM TO BE INSPECTED

Equipment is

Item

PROCEDURE: Check for and have repaired

Not Ready

No.

B

D

A

W

filled or adjusted as needed

Available If:

12

INSTRUMENTS AND GAGES

Check for proper indication and operation.

Any gage inoperative or not

within limits.

•

Fuel pressure:

4-6 psi (28-41 kPa)

•

Oil pressure:

60-80 psi (414-552 kPa)

•

Discharge pressure:

80-120 psi (552-827 kPa)

•

Ammeter:

Should indicate positive (+)

charge

•

Tachometer:

1400 rpm idle to 2500 rpm

max

•

Compressor

temperature:

150°F-230°F (66°C-110°C)

after 10 minutes of operation

13

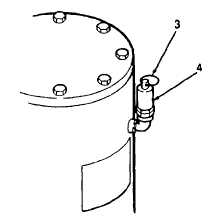

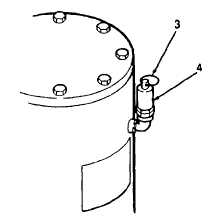

SAFETY RELIEF VALVE

•

Pull up on ring (3) of safety relief valve (4). Safety

relief valve should open and allow air pressure to es-

cape. If valve will not open, notify your supervisor.

14

SERVICE AIR MANIFOLD

•

Open and drain moisture from service air manifold

drain (5).

TA505400

2-12