Section III. PREVENTIVE MAINTENANCE SERVICES

noticed during operation which would damage the

73. Operator

equipment if operation continued. After operation services

To insure that the equipment is ready for operation at

will be performed by the operator for periods longer than 10

all times, inspect it systematically before operation, during

hours, the unit will be stopped and after operation service

operation, at halt, and after operation, so that defects may

will be performed at 10-hour intervals.

Defects or

be discovered and corrected before they result in serious

unsatisfactory operating characteristics beyond the scope

damage or failure. The necessary preventive maintenance

of the operator to correct must be reported to the proper

services will be performed before operation. Defects

authority. Responsibility for performance of preventive

discovered during operation of the unit will be noted for

maintenance services rests not only with the operator, but

future correction, to be made as soon as operation has

with the entire chain of command from section chief to

ceased. Stop operation immediately if a deficiency is

commanding officer (AR 7505).

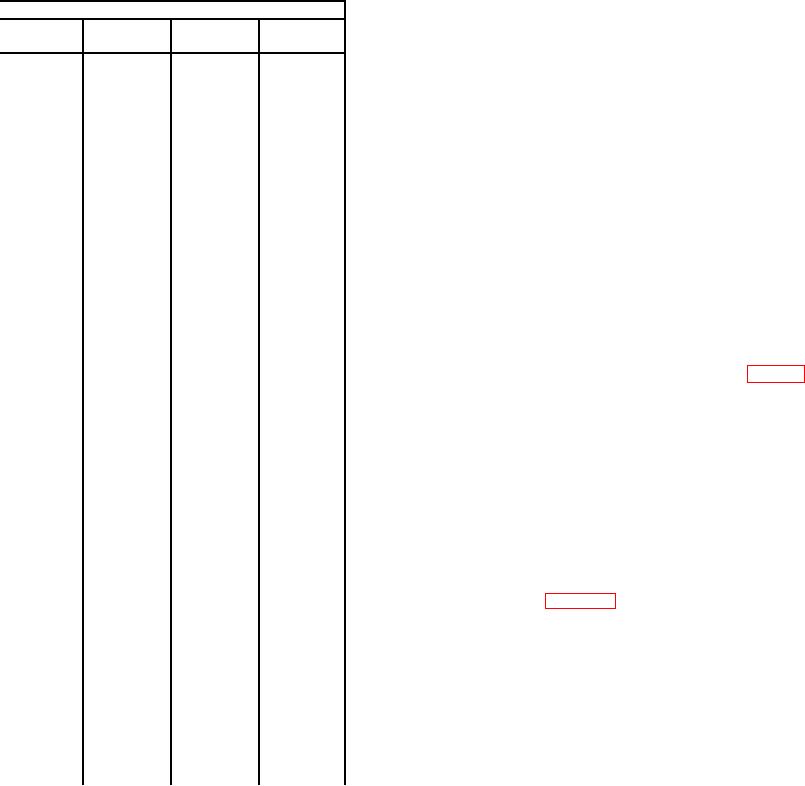

74. Operator's Daily Services

Intervals

Before

During

After

operation

operation

At halt

operation

PROCEDURE

X

X

X

X

Visual inspection. Visually inspect the entire unit for cracks, breaks,

and loose or missing assembly screws and lockwashers. Inspect

for any tampering or damage that may have occurred since the

lubricating unit was last operated. Correct deficiencies before

using the lubricating unit.

X

X

X

Fuel. Check the fuel supply. See that the fuel tank is full.

X

X

Leaks. Check for lubrication leaks and air leaks. Check swivel joints

at hose reel inlets.

Cleaning. Use a brush to remove loose dirt from the exterior of the

X

lubricating unit. Use an approved cleaning solvent to remove dirt

and grease accumulations.

Instruments. Check all gages for broken glass and secure mounting.

X

X

X

Draincock. Open the draincock for a short time to release moisture in

the air receiver.

Air cleaner. Frequently inspect and clean the air cleaner (par. 65g).

X

X

X

Inspect for secure mounting and loose connections. Check the

condition and level of oil in the bowl.

X

Unusual noises or operation. While operating the lubricating unit

check for any unusual noises which may indicate trouble.

Determine the cause of any excessive vibration or unusual noise

which may indicate loose or damaged parts, or lack of proper

lubrication. Stop the lubricating unit and correct the trouble or

report the condition to the proper authority.

X

Tools and equipment. See that all tools and equipment assigned to

the unit are in serviceable condition, clean, and properly stowed.

Fire extinguisher. Check the condition of the fire extinguisher and

X

inspect it for full charge (par. 61). Do not discharge contents.

See that it is securely mounted.

Protection. If freezing temperature is anticipated, drain all moisture

X

from the air receiver. Leave the drain valve open.

Lubrication.

Inspect the entire unit for missing or damaged

X

X

X

lubrication fittings, and for indications of insufficient lubrication.

Lubricate per (LO 5-4930-202-12).

Appearance. Inspect the general appearance of the unit, giving

X

X

particular attention to identification markings, and condition of the

paint.

39