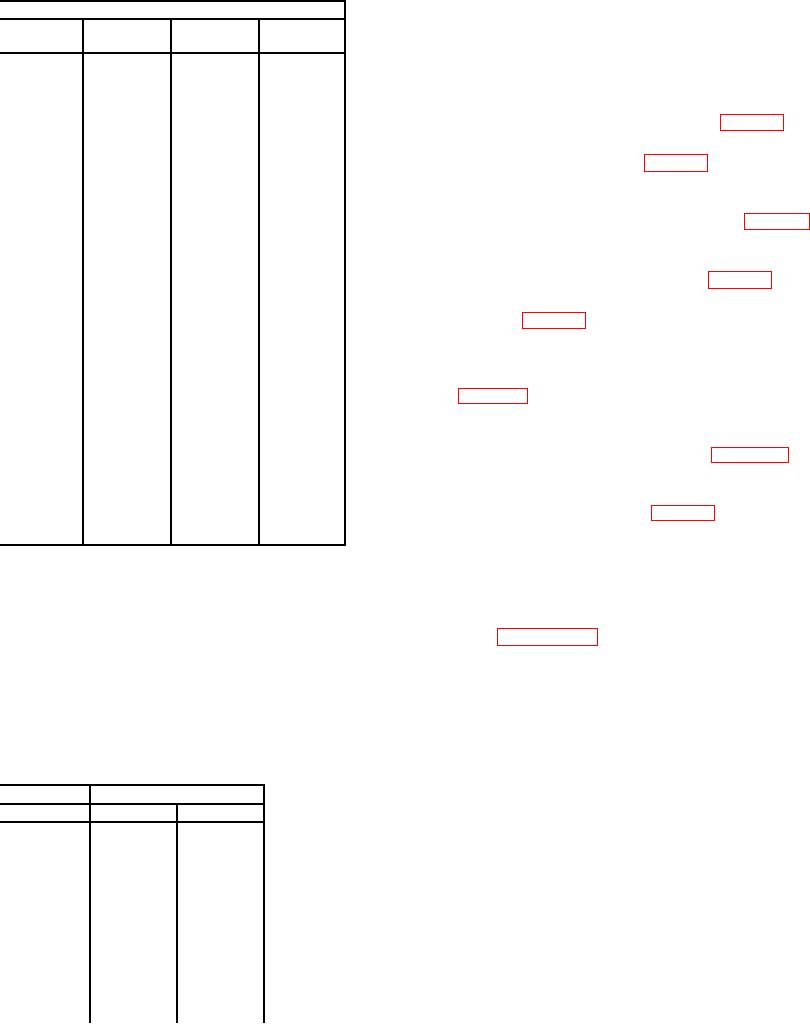

Intervals

Before

During

After

operation

operation

At halt

operation

PROCEDURE

X

X

X

Fuel filter. Inspect the filter sediment bowl for any accumulation of

dirt or water. Clean the sediment bowl and screen if dirt or water

are present. Replace bowl and gasket if necessary (par. 109).

X

X

Batteries. Check condition of batteries. Maintain proper electrolyte

level and make sure all cables are tight (par. 116).

X

X

X

Cylinder heads, manifolds, and gaskets. Inspect cylinder head,

manifold, and exhaust pipe for leaks, loose bolts, nuts, and

defective gaskets. Check condition of exhaust muffler (par. 123).

Cooling fins and shroud (engine). Inspect the cylinder head and

X

X

cooling fins, air shroud, and screen for any accumulation of dirt or

rust. Never operate engine with shroud removed (par. 122).

Fuel tank, cap, and gasket. Check fuel tank, fuel lines, and

X

X

X

connections for leaks (par. 113).

Inspect compressor head, cylinder cooling fins,

X

X

intercooler and flywheel fan for accumulation of dust or dirt.

Check ail connections for air leaks. See that crankcase breather

cap is clean (pars. 132 and 133).

Servicing equipment. Check all servicing equipment units for proper

X

X

operation. See that they are in serviceable condition, clean, and

properly stowed. Replace defective equipment (pars. 140 and

143).

Magneto. Inspect the magneto for loose mounting bolts and for oil

X

X

leaks around the mounting flange gasket (par. 115).

75. Organizational

Preventive maintenance is performed by organizational maintenance personnel at biweekly and bimonthly

intervals. The biweekly interval will be equivalent to a maximum of 50 hours of use. The bimonthly interval will be

equivalent of 8 weeks or a maximum of 250 hours of use, whichever occurs first. The preventive maintenance services

to be performed at these regular intervals are listed and described in paragraph 74. The numbers appearing at the

columns opposite each service refer to a corresponding number appearing on DA Form 464 and indicate that a report of

the services should be made at that particular number of the form. These numbers appear either in the second and/or

third columns as an indication of the interval at which the service is to be performed. The first column headed

"Inspection" is provided for the information of the personnel performing the inspection. A number in this column

indicates that an inspection should be made of the listed items in accordance with the instructions given in the text

opposite. The indicated items and instructions constitute the minimum inspection requirements.

76. Biweekly and Bimonthly Preventive Maintenance Services

Service

Inspection

Bimonthly

Biweekly

GENERAL

1

1

1

Before-operation services. Check and perform services listed in daily before-

operation services.

Lubrication. Inspect the entire unit for missing or damaged lubrication fittings,

2

2

2

lines, or grease cups, and for indications of insufficient lubrication. Check for

lubrication leaks from oil lines and gearcases, and for defective oil and grease

seals.

Replace missing or damaged fittings. Correct or report all leaks.

2

2

Tools and equipment. Inspect the condition of all tools and equipment assigned

3

3

3

to the unit. Check condition and mounting to tool compartments.

40