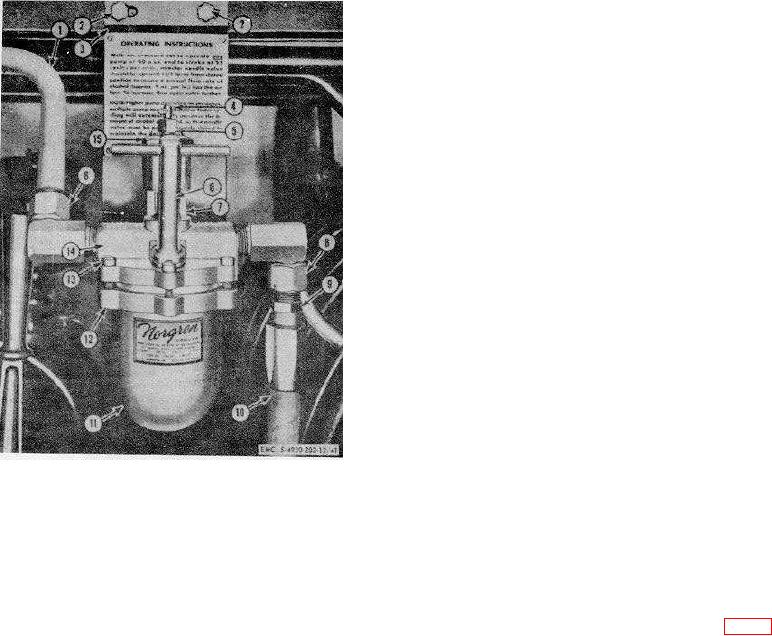

(4)

Remove the filler plug assembly (6) from the

top assembly.

(5) Remov e the needle valve (4) and gland from

the top assembly by removing the packing

nut (5) and top plug (15).

c. Cleaning, Inspection, and Repair.

(1) Clean all parts with an approved cleaning

solv ent.

(2) Inspect the sight glass for cracks.

(3) Inspect all fittings and threaded connections

for damage. Replace defective parts.

(4) Inspect the bowl for dents or holes. Replace

a defective bowl. Replace bowl gasket.

(5) Inspect the needle valve. Replace if dam-

aged.

d. Reassembly.

(1) Install the needle valve (4) and gland in the

top assembly (14) and secure with top plug

(15) and packing nut (5).

(2) Install the filter plug assembly (6) on the top

assembly (14).

(3) Install the bowl gasket on the bowl (11).

Place the bowl in position on the top

assembly, and secure by installing the ring

clamp (12) and six screws (13).

1

Air line, alcohol dispenser-to-regulator

(4) Install the two adapters (8), one to each side

2

Cap screws, 1/4-20 x 1/2 in. lg (2 rqr)

of the top assembly.

3

Mounting bracket

4

Needle valve

e. Installation.

5

Packing nut

(1) Install the alcohol dispenser and mounting

6

Filler plug assembly

bracket (3) on the lubricator frame and

7

Sight feed glass

8

Adapter, 90' union

secure with the two cap screws (2).

9

Air hose connection to alcohol dispenser

(2) Connect the air line (1) and air hose (10) to

10

Air hose

the alcohol dispenser adapters (8).

11

Bowl

12

Ring clamp

(3) Open the master control valve (2, fig. 8) on

13

Screws, 3/16-20 x 3/4 in. Ig (6 rqr)

the air receiver tank (10).

14

Top assembly

(4) Inspect the alcohol dispenser for leaks

15

Plug, top

during operation.

Figure 41. Alcohol dispenser.

86