take off the end cover plate (18) and cover plate gasket (19). Remove the commutator-end bearing (20).

NOTE

The bearing may remain on the shaft when the commutator-end frame is removed.

Leave it on the shaft if it is not defective.

d. Cleaning and Inspection.

(1) General. Clean and inspect ail parts, and replace any defective parts.

(2) Armature. Do not clean the armature by any degreasing method, since this would damage the insulation

and ruin the armature. 'Wipe with a clean cloth slightly dampened with carbon tetrachloride or similar

solvent. If the commutator is rough, out-of-round, worn, has high mica, filled slots, or is burned, turn down

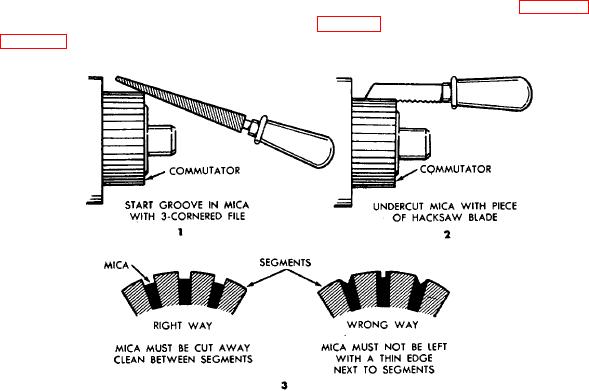

the commutator in a lathe, and undercut the mica. Use a mica undercutter (par. 179) for this purpose, if

available, or use a hacksaw blade as shown in figure 79. Follow the numerical sequence (1), (2), and (3) in

Figure 79. Correct method of undercutting mica.

(a) Ground. Use a test lamp to check for grounds from the ends of the commutator segments to the end of the

armature shaft or lamination. Do not place the test probes on the commutator or bearing surface or the

arching will mar the polished surfaces. If the test

184