TM 5-4310-354-14

TS 5-4310-14/4-9

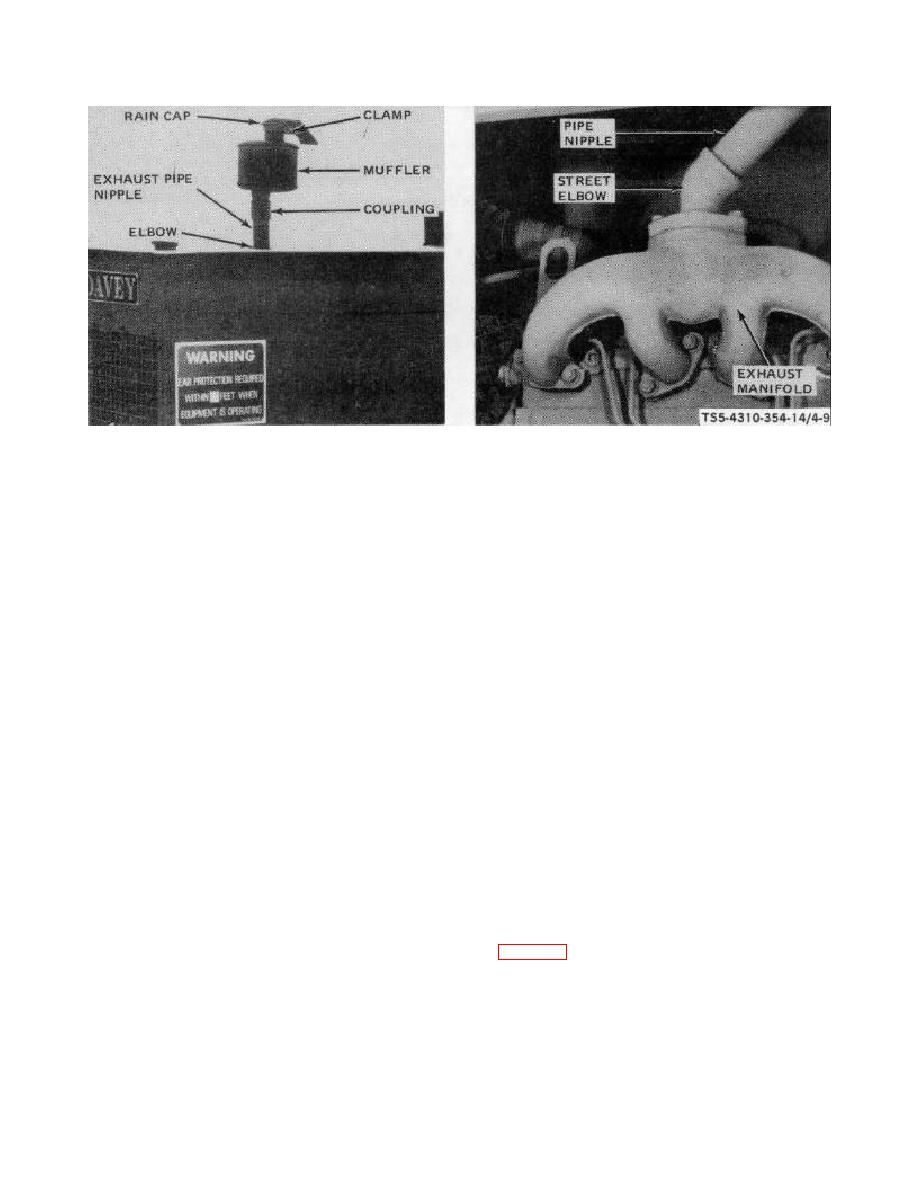

A MUFFLER AND EXHAUST EXTENSION

B EXHAUST MANIFOLD INSTALLATION

REMOVAL

STEP 1.

AS NECESSARY, INSTALL STREET

ELBOW

IN

ENGINE

EXHAUST

STEP 1.

LOOSEN NUT ON RAIN CAP CLAMP,

MANIFOLD, INSTALL PIPE NIPPLE,

TAP RAIN CAP WITH A HAMMER AND

ELBOW, NIPPLE, AND COUPLING.

REMOVE RAIN CAP FROM MUFFLER.

STEP 2.

INSTALL

EXHAUST

MUFFLER

IN

STEP 2.

UNSCREW AND REMOVE MUFFLER

COUPLING.

FROM EXHAUST PIPING COUPLING.

STEP 3.

INSTALL RAIN CAP ON MUFFLER AND

STEP 3.

AS

NECESSARY,

UNSCREW

AND

TIGHTEN CLAMP NUT.

REMOVE PIPE COUPLING, NIPPLE,

ELBOW, NIPPLE, AND STREET ELBOW

FROM ENGINE EXHAUST MANIFOLD.

b. Cleaning and Inspection.

WARNING

(1) Use a wire brush to remove all scale

Dry cleaning solvent, P-D-680, used

deposits and carbon.

After brushing,

to

clean

parts

is

potentially

clean parts in cleaning solvent, Federal

dangerous

to

personnel

and

Specification P-D-680, Type II.

property.

Avoid repeated and

prolonged skin contact. Do not use

(2) Inspect parts for cracks, breaks, or any

near open flame or excessive heat.

other defects.

Flash point of solvent is 100 F-138 F

(38 C - 59 C).

in figure 4-9.

4-24