TM 5-4310-354-14

4-71. Fuel Injection Pump Solenoid.

a. Removal. Notify Direct Support Maintenance if

removal of fuel injection pump solenoid is necessary.

b. Cleaning and Inspection.

(1) Wipe the fuel injection pump solenoid with

a clean, dry cloth.

(2) Inspect the solenoid lead terminals and

wire connections for evidence of shorts

and for tightness of terminal connections.

(3) Make certain solenoid is wired properly

(refer to figure 1-3).

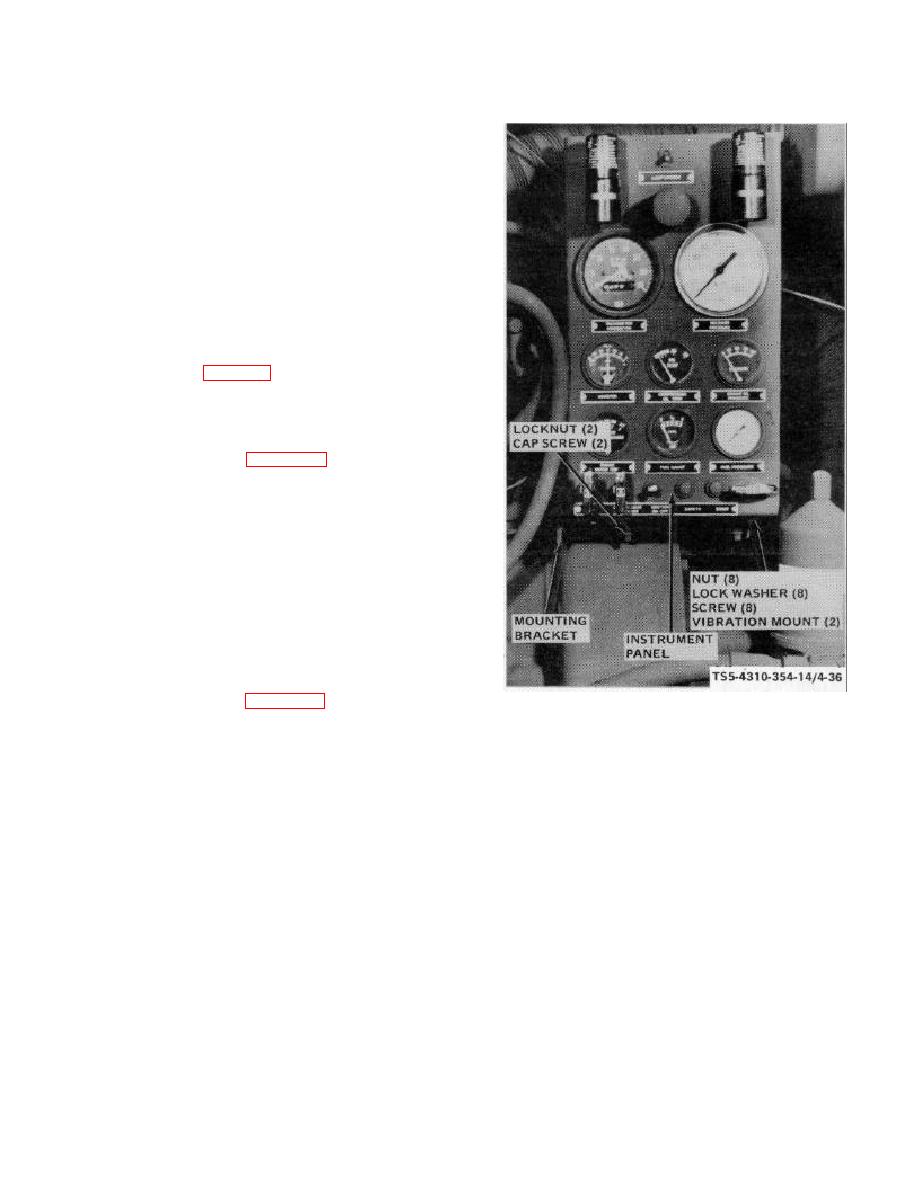

4-72. Instrument Panel Vibration Mounts.

a. Removal.

Remove the instrument

panel

vibration mounts as shown in figure 4-36.

b. Cleanin g and Inspection.

(1) Wipe the vibration mounts with a clean,

dry cloth.

(2) Inspect the mounts for deterioration, cuts,

and breaks.

(3) Inspect attaching hardware for damaged

threads or any other defect.

TS5-4310-354-14/4-36

c. Installation.

Install the instrument

panel

vibration mounts as shown in figure 4-36.

REMOVAL

STEP 1.

REMOVE LOCKNUT AND CAP SCREW

THAT ATTACH VIBRATION MOUNT TO

INSTRUMENT

PANEL

MOUNTING

BRACKET.

STEP 2.

REMOVE NUTS, LOCK WASHERS, AND

SCREWS THAT ATTACH VIBRATION

MOUNT TO INSTRUMENT PANEL.

INSTALLATION

STEP 1.

INSTALL

VIBRATION

MOUNT

ON

INSTRUMENT PANEL.

SECURE WITH

SCREWS, LOCK WASHER, AND NUTS.

STEP 2.

INSTALL CAP SCREW AND LOCK NUT TO

SECURE

VIBRATION

MOUNT

TO

INSTRUMENT

PANEL

MOUNTING

BRACKET.

Figure 4-36. Instrument panel vibration mounts, removal

and Installation.

4-82