TM 5-4310-354-14

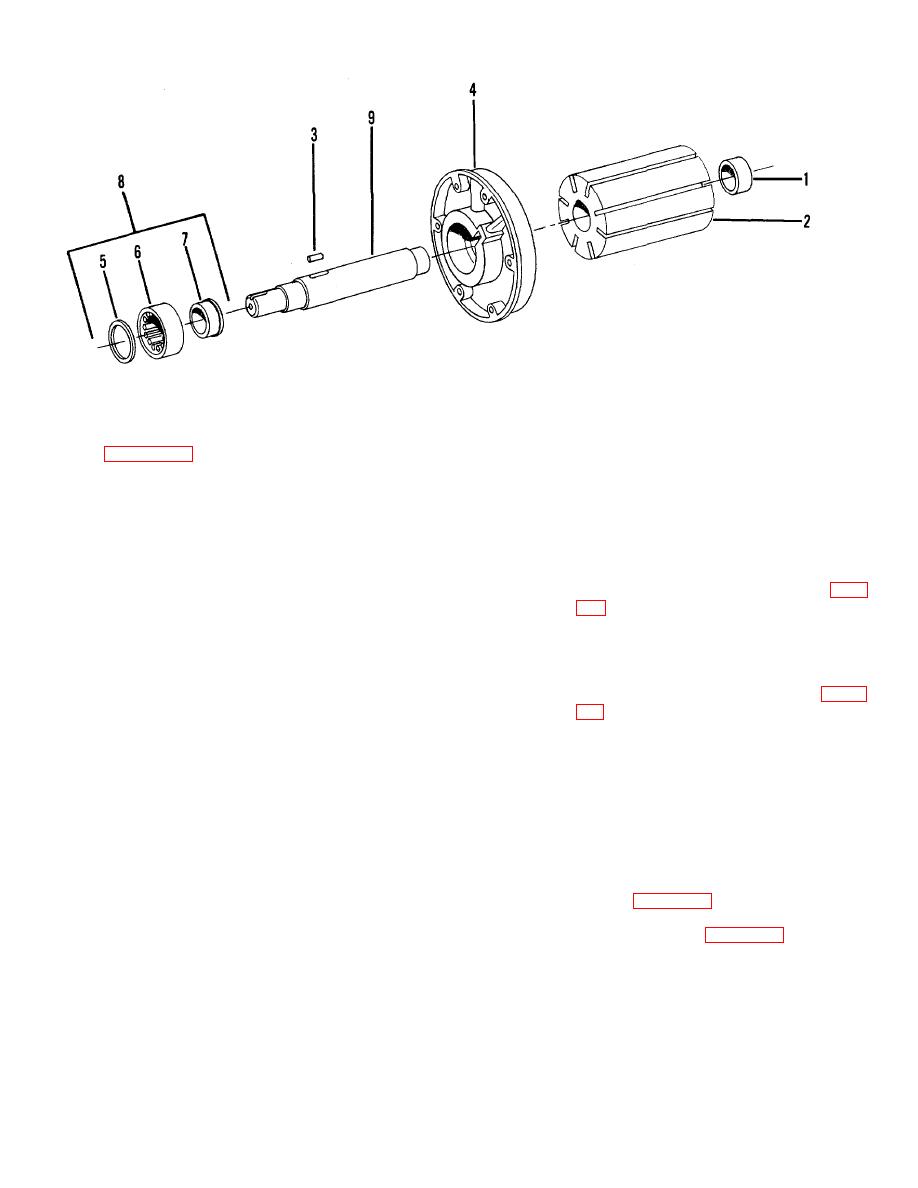

1.

Bearing inner race

6.

Bearing outer race

2.

Rotor

7.

Bearing inner race

3.

Rotor key

8.

Bearing assembly

4.

Drive end cover

9.

Rotor shaft

5. Bearing ring

TS5-4310-354-14/6-9

Figure 6-9. Drive end cover-rotor, disassembly and reassembly.

CAUTION

NOTE

Do not heat bearing inner races (1, 7,

If inner race (7) cannot be removed

with a puller, use a torch to heat the

intended to replace the entire

race evenly. While race is still hot,

bearing.

Excessive heat causes

pull off of shaft as quickly as

softening of the metal; therefore, any

possible. Discard entire bearing (8)

bearing heated for removal shall be

when race (7) is removed by heating.

replaced.

c. Cleaning, Inspection, and Repair.

(a) Remove bearing ring (5) from rotor

shaft extension. Use a gear puller,

(1) Clean all parts in accordance with para

or equivalent, and pull bearing inner

race (1) from rotor shaft (9).

(2) Inspect all springs for defective coils,

cracks, distortion, or any other defect.

NOTE

(3) Inspect intake control diaphragm (5, figure

If inner race (1) cannot be removed

with a puller, use a torch to heat the

defect.

race evenly. While race is still hot,

pull off of shaft as quickly as

(4) Inspect intake valve (13) for cracks,

possible.

Discard entire bearing

distortion, condition of seat, excessive

when race was removed by heating.

wear, or any other defect.

(b) Remove rotor (2) from rotor shaft (9)

and remove rotor key (3) from shaft

(5) Inspect rotor blades (73) for cracks,

(9) keyway.

chipping, excessive wear, or any other

defect. If blades are worn on one side

(c) Remove drive end cover (4) from

only, they can be turned over and reused.

rotor shaft (9). Remove bearing

Refer to figure 6-11.

outer race (6).

(6) Inspect rotor (77, figure 6-8) and stator

(d) Use a gear puller, or equivalent, and

(93) for cracks, scoring, excessive wear,

pull bearing inner race (7) off of

raised metal, or any other defect.

rotor shaft (9).

6-17