TM 5-4310-354-14

(6) If removed, reassemble stator lead clips

(15) to stator (14) leads. Reassemble

rectifier bridge (16), stator assembly (14),

diode trio (13), lock washer (12), screw

(11), make lead connections and

assemble three lock washers (10) and

nuts (9).

CAUTION

Do not overtighten vise when holding

rotor assembly (8) for reassembly of

items (7 through 2).

(7) Place rotor assembly (8) in a vise and

tighten just-enough to keep it from turning

when tightening nut (2). Assemble drive

end frame (7), outside collar (6), fan (5),

pulley (4), lock washer (3), and nut (2).

Tighten nut (2) to 40-60 foot-pounds (5.5-

8.3 kg meters).

(8) Remove rotor assembly from vise and

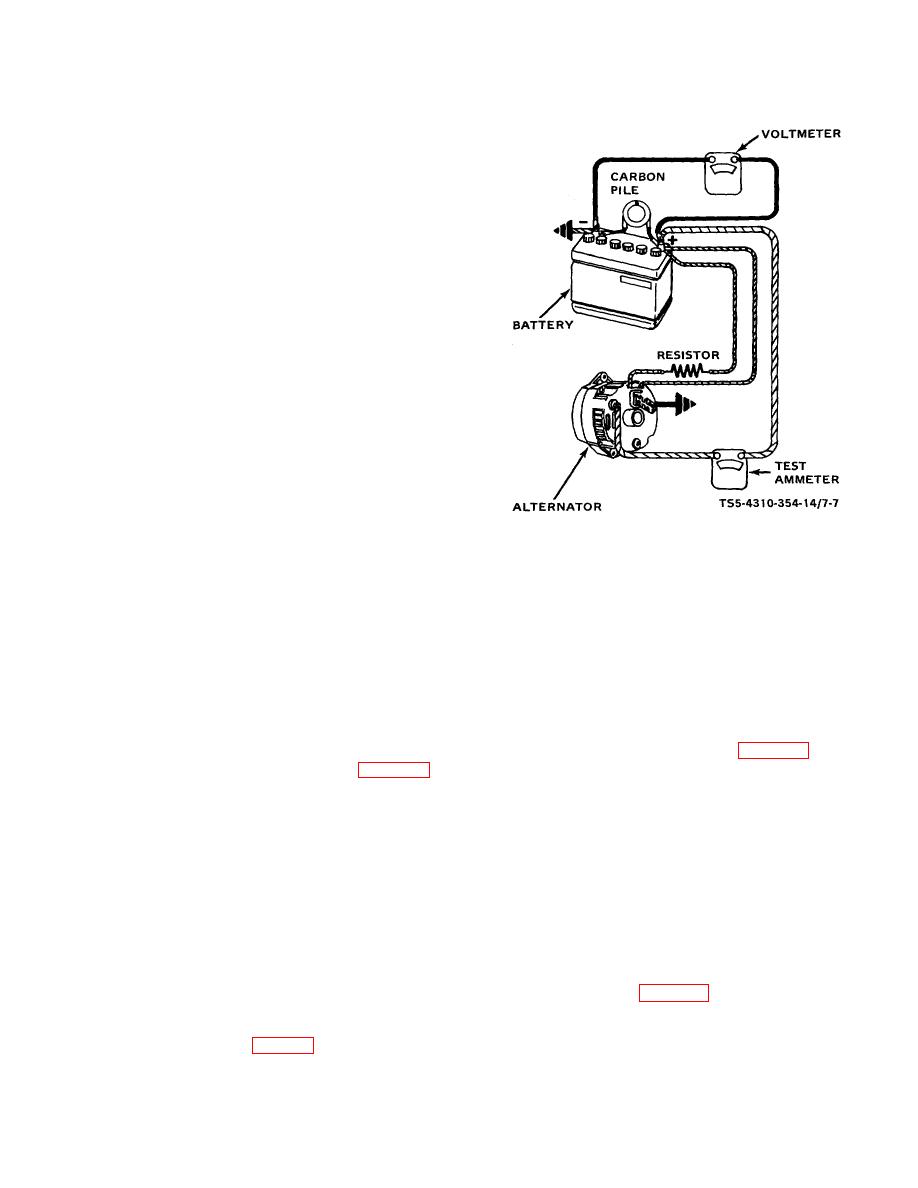

TS5-4310-354-14/7-7

remove protective tape installed at

disassembly. Make certain that rotor shaft

Figure 7-7. Alternator bench testing.

and bearing are clean.

Insert a pin

through hole in slip ring end frame (31) to

Overcharged Battery. If not grounded,

hold up the brushes. Carefully assemble

test regulator with an approved regulator

the end frame (31) onto rotor assembly

test or, and check field winding.

shaft aligning the scribe marks made at

disassembly. Install the through bolts (1)

NOTE

and remove the brush retaining pin to

allow brushes to drop onto slip rings.

The battery MUST be fully charged

when making this check.

assembly before installing on engine, make setup in a

(4) If voltage is below 15.5 volts, connect the

test stand and test as follows:

carbon pile as shown in figure 7-7.

(1) Make connections as shown in figure 7-7,

(5) Operate the alternator at moderate speed

except do not connect carbon pile at this

as required and adjust the carbon pile as

time. IMPORTANT: Ground polarity of

required to obtain maximum current

battery and alternator must be the same

output.

negative. Use a fully charged battery and

a 10-ohm resistor rated at six watts or

(6) If output is within 10 amperes of rated

more between alternator No. 1 terminal

output of 37 amperes (stamped on drive

and the battery.

end frame), the alternator is good.

(2) Start the test stand and slowly increase

(7) If output is not within 10 amperes of rated

the alternator speed and observe the

output, keep battery loaded with carbon

voltage.

pile and ground the alternator field as

shown in figure 7-8.

(3) If the voltage is uncontrolled with speed

and increases above 15.5 volts, check for

a grounded brush lead clip. Refer to

troubleshooting table 5-1 under heading of

7-7