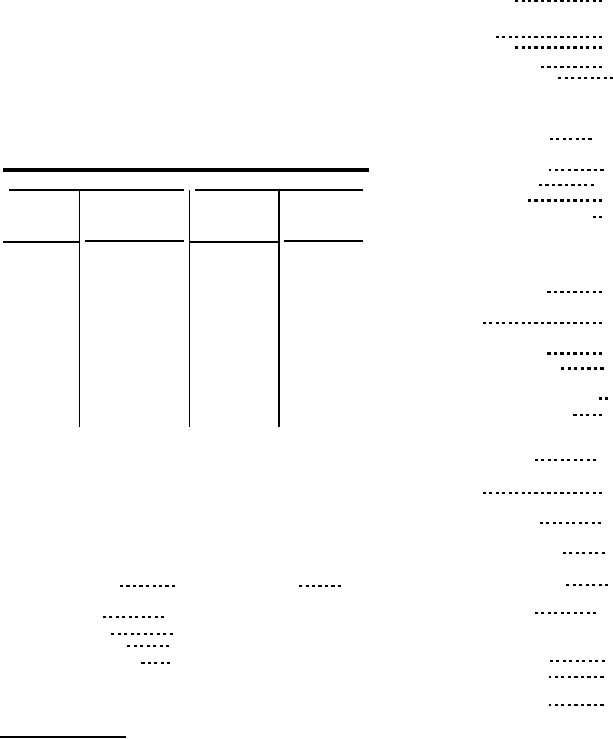

Minimum flow .......................3.5 scfm

Original

Wear

Minimum reseal pressure 1, 950 psig

Component

dimensions

limits

Leakage rate ............... 3 cc. per min.

Min (In.)

Max

(In.) (In.)

(5) Gasoline engine.

SECOND STAGE CYLIN-

Make Military Standard ............ A08-3

DER AND PISTON

Type ....................... 4-cycle, gasoline,

ASSEMBLY

overhead valve, air-cooled

*Cylinder bore

0.9687

0.9688

Number of cylinders .........................1

Piston-to-cylinder Wall

Bore .................................... 2.250 in.

clearances

0.0002

0.0004 0.0003

Stroke .........................................2 in.

Wristpin hole

0.4366

0.4368 0.0002

Piston displacement............... 8 cu in.

Wristpin diameter

0.4363

0.4365 0.0001

Compression ratio.........................6:1

Piston head clearance 0.002

0.006

THIRD STAGE CYLIN-

Horsepower (at 3, 600 rpm) ..........1.5

DER AND SLEEVE

ASSEMBLY

b. Recommended Wrench Torque for Steel Nuts

*Cylinder bore

0.4050

0.4055

and Bolts.

Piston-to-cylinder

wall clearance

0.00020

0.00025 0.0002

National Fine

National Coarse

Wristpin hole

0.4366

0.4368 0.002

Wristpin diameter

0.4363

0.4365 0.0001

Thread

Thread

Piston head clearance 0.002

0.006

size

(pound-

size

(pound-

COMPRESSOR CON-

foot)

foot)

NECTING LINKS

8-32

1 to 2

8-32

1 to 2

AND MASTER ROD

10-32

1 to 2

10-24

1 to 2

Connecting link wristpin

1/4-28

5 to 8'

1/4-20

4 to 6

bearing hole

0.5615

0.5620 0.0002

5/16-24

10 to 15

5/16-18

8 to 12

Master rod connecting

3/8-24

18 to 27

3/8-15

15 to 22

link holes

0.4366

0.4368 0.0003

7/16-20

28 to 42

7/16-14

24 to 36

First stage wristpin

1/2-20

45 to 68

1/2-13

37 to 56

bearing hole

0.5590

0.5594 0.0002

9/16-18

64 to 97

9/16-12

56 to 83

Shaft bearing hole

1.8750

1.8754 0.0003

5/8-18

98 to 138

5/8-11

75 to 112

ENDBELL

3/4-16

158 to 242

3/4-10

137 to 200

Shaft seal bore diameter 1.499

1.500 0.0005

7/8-14

258 to 384

7/8-9

218 to 316

Bearing bore diameter 1.8502

1.8505 0.0001

1-14

400 to 600

1-8

316 to 484

COMPRESSOR SHAFT

Shaft seal diameter

c

Wear Limits.

(fan end)

0.934

0.940

0.002

Bearing diameter

Original

Wear

(fan end)

0.9842

0.9845 0.0001

Component

dimensions

limits

Master rod journal

diameter

.8724

1.8728 0.0003

Min (In.)

Max

(In.) (In.)

Bearing diameter (op-

FIRST STAGE CYLIN-

posite fan end)

.1809

1.1811 0.0001

DER AND PISTON

Shaft seal diameter

ASSEMBLY

(opposite fan end)

1.059

1.065

0.002

*Cylinder bore

2.1875

2.1876

RETAINER PLATE

Piston-to-cylinder wall

Thickness

0.092

0.094

0.002

clearance

0.0003

0.0005 0.0005

Retainer pinhole diameter 0.253

0.257

0.002

Wristpin hole

0.3754

0.3756 0.0002

OIL PUMP PISTON

Wristpin diameter

0.3751

0.3753 0.0001

Large diameter

0.5595

0.5605 0.001

Piston head clearances

0.021

0.026

Small diameter

0.3790

0.3795 0.0005

OIL PUMP CYLINDER

Inner diameter

0.3798

0.3801 0.0005

*Cylinder bore may be sip to 0.001 oversize for matching with piston diameter; clearance is held as stated.

5