CHAPTER 2

DIRECT SUPPORT MAINTENANCE INSTRUCTIONS

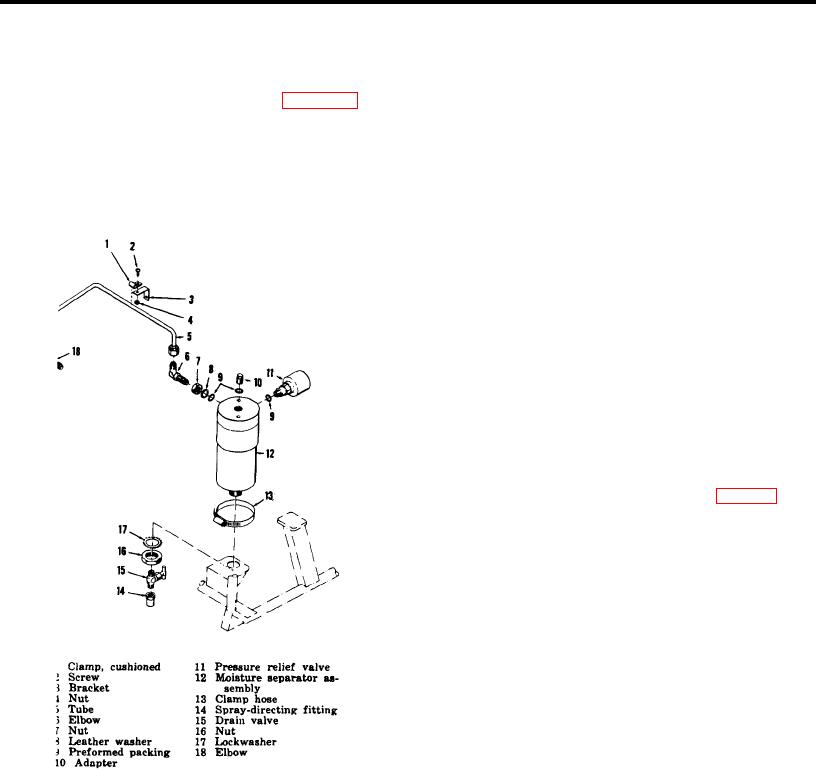

Section I. MOISTURE SEPARATOR GROUP

2-1.

Description

2-2. Function

The moisture separator group (fig. 2-1) is

The moisture separator group serves to sep

located on the frame of the compressor and 3 held in

arate moisture and impurities from the high-pressure

place by a clamp (13). The moisture separator group

compressed air.

These impurities are removed

consists of a tube assembly (5), elbows (6 and 18),

periodically by opening the drain valve mounted on the

adapter (10), pray-directing fitting (14), drain valve (15),

base of the moisture separator assembly, thus allowing

pressure relief valve (11), and a moisture separator

high-pressure air to blow the accumulated moisture and

assembly (12).

oil condensate to atmosphere through the spray-directing

fittings. The pressure relief valve mounted in the

moisture separator assembly opens automatically to

exhaust high-pressure to atmosphere before pressure in

the shell reaches 2, 250 pounds per square inch. The

relief valve reseals, or closes, preventing the further

escape of air when pressure within the shell drops to 1,

950 pounds per square inch.

2-3.

Maintenance

Direct support maintenance personnel are

authorized to replace the clamp, backup washer,

adapter, drain valve, pressure relief valve, moisture

separator assembly, and hardware as required.

a.

Removal.

(1) Open drain valve (15, fig. 2-1) and

drain the moisture separator assembly.

(2) Remove screw (2) and nut (4)

attaching clamp (1) to bracket (3).

Remove tube assembly (5) from

between after cooler and moisture

separator. Remove bracket (3).

(3) Remove elbows (6 and 18). Remove

nut (7), washer (8), and packing (9).

Unscrew and remove adapter (10) and

packing (9). Remove pressure relief

valve assembly (11) and packing (9).

(4) Unscrew and remove fitting (14) from

drain valve (15). Remove drain valve.

Figure 2-1. Moisture separator group, exploded view.

Unscrew and remove nut (16) and

lockwasher (17).

6