TM 3-4310-100-20 & P

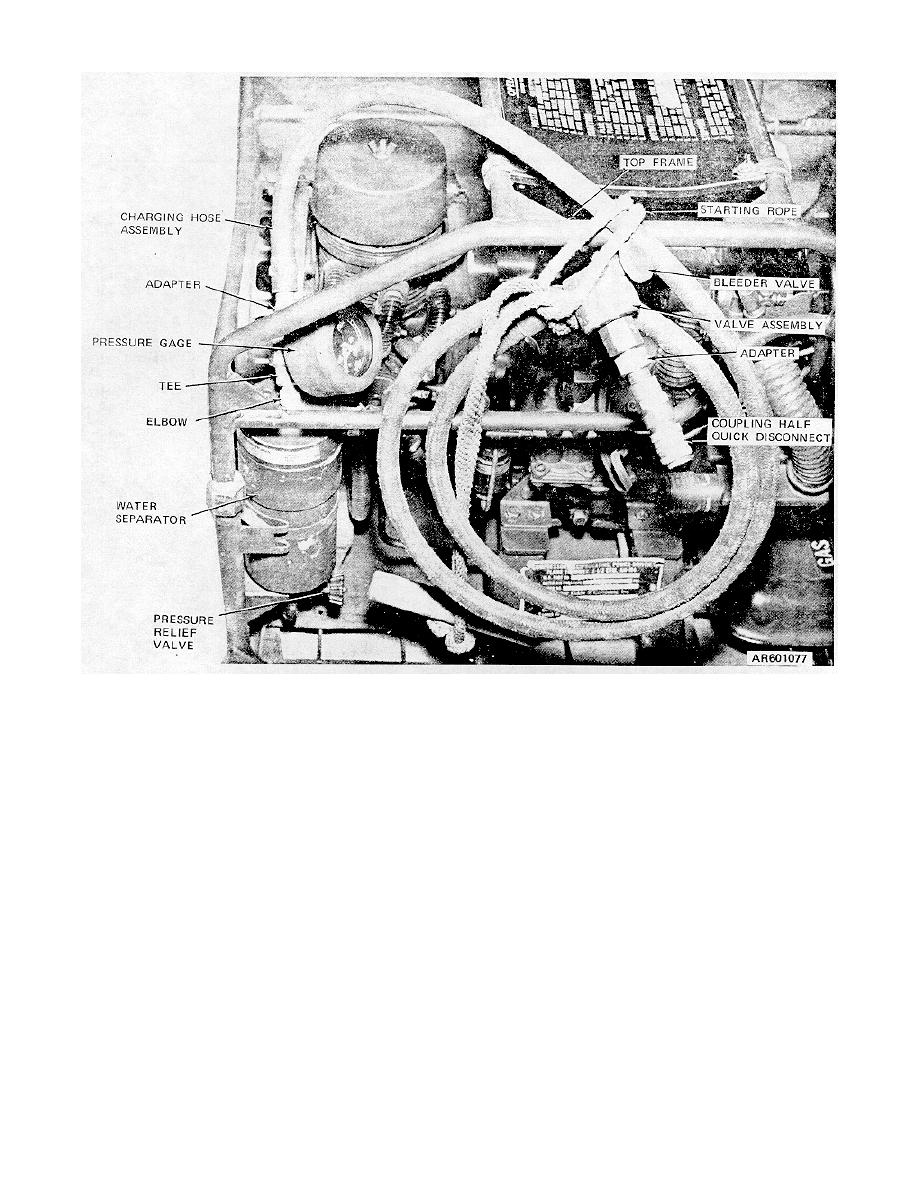

Figure 1-1. A typical AN-M4 Compressor unit model with charging hose assembly connected to water separator.

b.

Components.

(5) Fuel Tank.

The fuel tank holds

(1) Air Compressor. The air compressor is a

approximately 3 quarts of fuel; sufficient for 3 hours of

operation.

three stage radial reciprocating compressor that will

(6) Bottom Frame and Top Frame. The rigid

deliver 3-1/2 CFM of high pressure air at 2.(000 psi,

tubular bottom frame.

provides mounting for the

when the engine operates at a speed of '3.60() rpm. The

gasoline fuel tank, gasoline engine, compressor, water

compressor operating temperature :range is 0 to 100 F.

(2) Water Separator. The operating pressure

separator. strap assemblies and the back rest harness.

A removable top frame is assembled to the bottom frame

of the water separator is 2,000 psi with a minimum burst

to protect both the gasoline engine and air compressor.

pressure of 5,000 psi. The assembly contains a high-

The top frame also supports the canvas cover.

pressure relief valve, with a condensate globe valve at

(7) Back

Rest

Harness

and

Strap

the base to permit discharge of accumulated air-water-oil

Assemblies. The back rest provides a comfortable

emulsion.

(3) Pressure Relief Value.

The pressure

support when carrying the compressor unit. The web

relief valve has a relief pressure of 2,250 psig, and a

shoulder and waist strap assemblies are bolted to the

reseating pressure of 1,950 psig.

bottom frame and are provided with quick release

(4) Gasoline Engine. The engine is a one-

buckles and snaps.

(8) Canvas Cover. The cotton duck canvas

cylinder, 4-cycle, overhead valve, air-cooled type. It will

cover is designed to fit snuggly over the

develop 1.5 horse-power at 3,600 rpm.

The engine is fungus-proof and fully suppressed to

climate radio interference.

1-2