b. Be sure any carbon deposits are removed from

bore, especially where throttle valve seats in

casting.

c. Blow out all passages with compressed air.

2. Disassembly of Carburetor-Up Draft

d. Replace all worn and damaged parts. Always

a. Remove carburetor from engine.

use new gaskets

b. Remove bowl cover and gasket.

c. Remove float pin, float, needle, and needle

seat. Check float pin for wear.

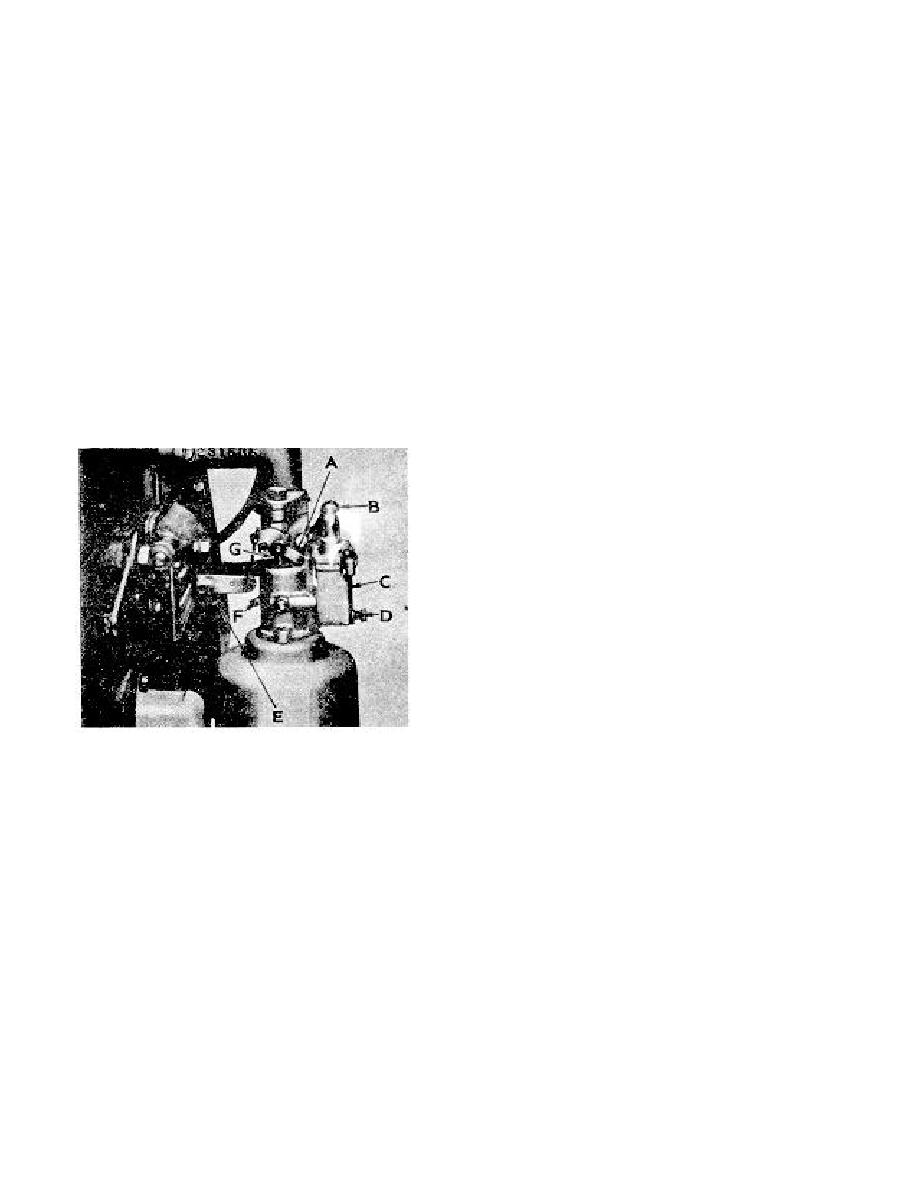

d. Remove idle mixture screw ("A", figure 4) and

high speed adjustment screw ("D", figure 4) and

springs. Do not remove choke valve and shaft

unless replacement of these parts is necessary

3. Cleaning Carburetor Parts

a. Clean all parts in solvent. Gum is easily

removed with an alcohol or acetone solvent.

4. Assembly of Carburetor--Up Draft

a. Install throttle shaft and valve. Elongated side

of valve should be towards top.

b. Install needle seat. A 5/16 socket should be

used.

Caution:

Do not over tighten. Torque to 25

to 30 inch-pounds.

c. Install needle, float. and float pin.

d. Set float level. With bowl cover casting inverted

and float resting lightly against needle in its

seat, there should be 7/16 clearance between

machined surface casting and free end of float

(side opposite needle seat).

Figure 4

e. Adjust by bending lip of float with small

screwdriver.

Up-Draft Carburetor

f. Install new bowl cover gasket, bowl cover and

A - Idle Adjustment Screw

D - High Speed Adjustment

bowl cover screws. Tighten securely.

Screw

B - Fuel Line

E - Governor Arm

g. Install high speed adjustment screw ("D" figure

C - Carburetor Bowl

F - Choke Lever

4.) Turn in until screw seats in nozzle and back

G - Idle Speed Screw

out two turns.

h. Install idle mixture screw ("A", figure 4.) Back

out approximately 1/2 turns after seating lightly

against jet.

i. Install idle speed regulating screw and spring.

Adjust desired idling speed with engine running.

68