Note:

The first or "SP" or "S" mark will

;appear 20 before top dead

center. The second mark is top

dead center and is stamped with

"DC" or "T" below the mark.

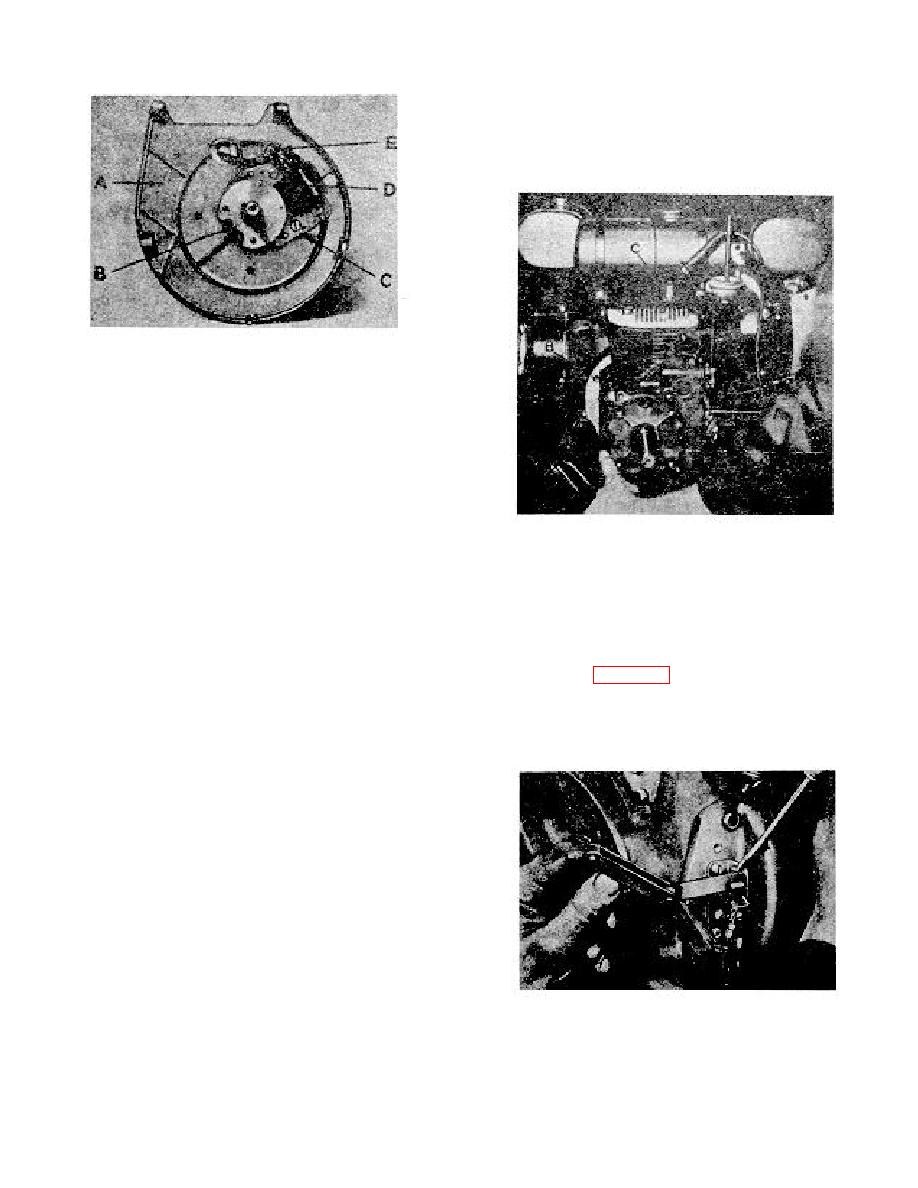

Figure 11

Phelon Magneto

A - Bearing Plate

C - Pole Shore

B - Magneto Rotor

D - Magneto Coil

E - Condenser

b. If there is no spark, check breaker points.

c. To test magneto, use a good commercial tester.

Refer to tester manufacturer's instructions for

Figure 12

acceptance limit of coils.

Setting Breaker Points with Timing Light

4. Testing Condenser

A - Breaker Points

B - Timing Sight Hole

C - Timing Light Attached to Spark Plug

Check condenser with reliable commercial con-

denser tester.

c. On earlier engines without timing sight hole,

point gap should be set at .020 when fully

5. Magneto

opened. Figure 13.

a. The K141 engine is equipped with the Phelon

d. Point clearance should be approximately .020

magneto as shown in figure 11.

fully opened. Clearance may vary a few

thousandths to achieve exact timing. This

b. The rotating magnet in both cases is mounted

variation is permissible.

directly on the crankshaft. Clearance between

the rotating magnet and pole shoes should be

about .002-.005.

c. Rotating magnet and flywheel are positioned on

the crankshaft with a single 1/4"square key.

6. Ignition Timing

a. Current production engines are equipped with a

timing sight hole in left side of bearing plate,

when viewed from power-take-off side of

engine.

b. If a timing light is available, set breaker point

Figure 13

gap while engine is running between 1200 and

Adjusting Points

1800 RPM. Adjust until "SP" or first mark on

flywheel is centered in sight hole. See figure

12.

71