TM 5-4310-227-15

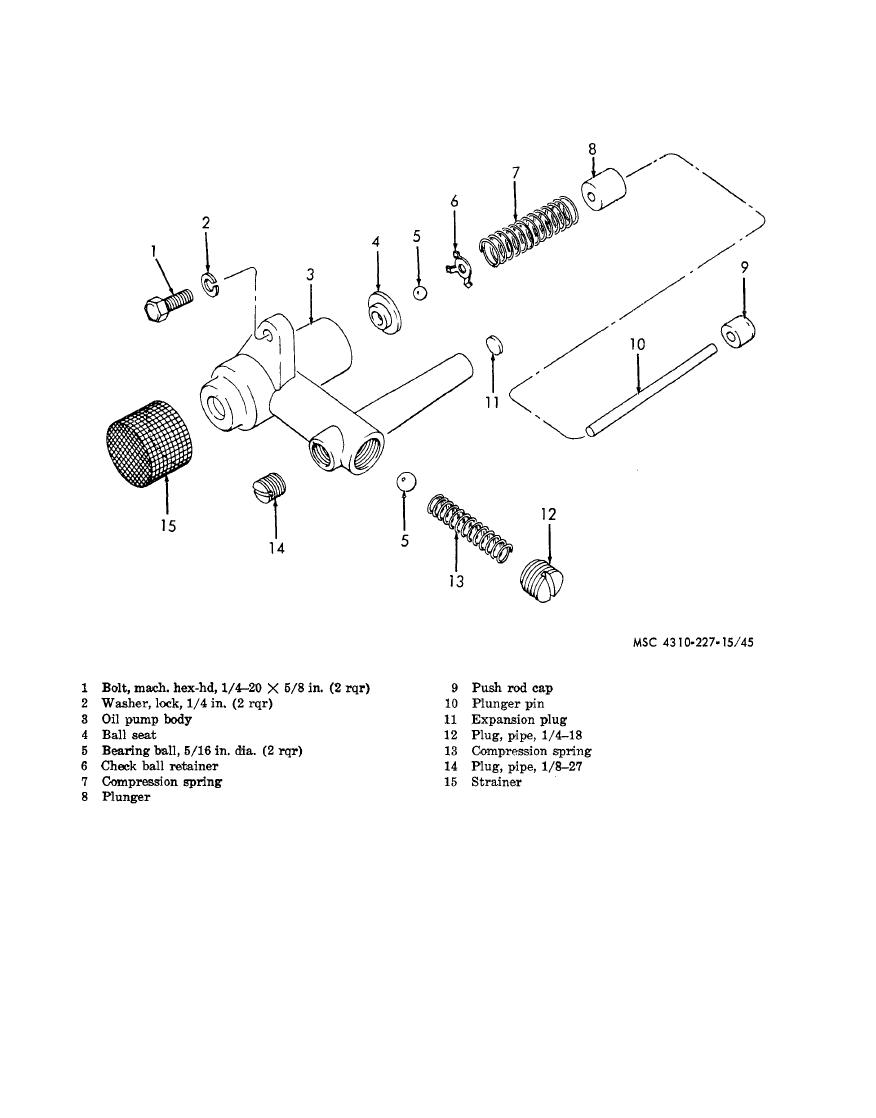

Note. Inspect the condition of the bear-

(3) Remove the pipe plug (12) from the

ing ball seat prior to removal. Do not

threaded hole in the side of the oil

remove the seat unless it is damaged or

pump body; then remove the outlet

worn (c (3) below).

compression spring (13 ) and bearing

(6) Remove the expansion plug (11) from

ball (5) from the same hole.

the top of the outlet spray nozzle on

(4) Remove the pipe plug (14) from the

the oil pump body (3).

threaded hole in the bottom of the oil

pump body.

Note. This plug should not be removed

(5) Using a suitable arbor press, remove

unless damaged or if the outlet spiny noz-

the ball seat (4) from the seat bore in

zle is excessively clogged and cannot be

the oil pump body.

properly cleaned with the plug installed.

4-23