c. When engine warms up pull inlet temper-

2-13. Operation in Extreme Cold (Below

ature control handle out for temperatures

0 F)

above 50 degrees F. Push handle in for tem-

a. Refer to current lubrication order for

peratures below 25 degrees F. Place handle

proper grade of lubrication.

halfway in for temperatures between 25 de-

b. Keep the fuel tank as full as possible and

grees F and 50 degrees F.

refill after operation to prevent condensation

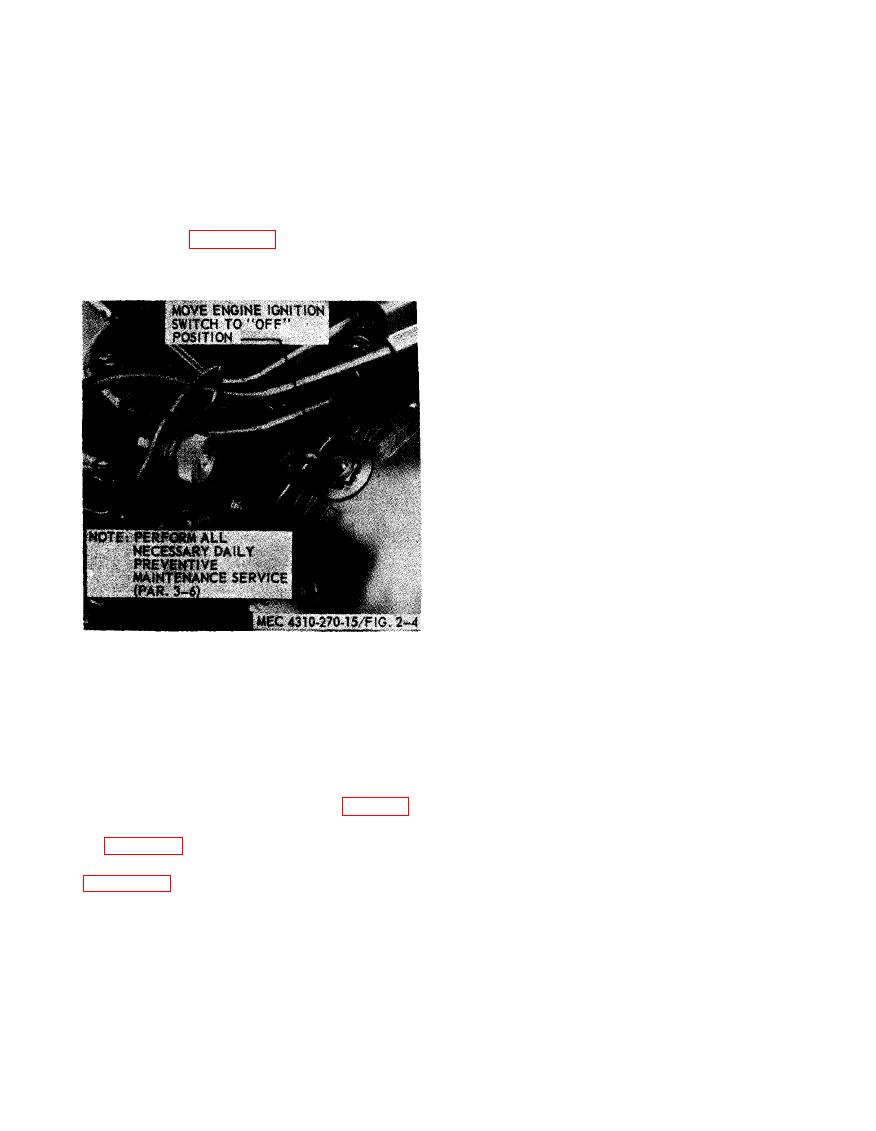

2-12. Stopping

from forming within the tank.

c. Clean the fuel filter sediment bowl more

frequently than usual.

compressor.

d. Clean snow and ice from lubrication

points before lubricating.

e. Inlet temperature handle must be pushed

all the way in for temperatures below 25 de-

grees F.

2-14. Operation in Extreme Heat

a. Refer to current lubrication order for the

proper grade of lubricants. Lubricate engine as

described in LO 5-2805-208-14.

b. Check the air shrouds of the engine for

insufficient ventilation of the engine. Clean

air shrouds at regular intervals.

c. Inlet temperature handle must be pulled

all the way out for temperatures above 50 de-

grees F.

d. The blower air filter must be kept clean

or replaced more frequently.

a. Lubricate unit in accordance with the cur-

rent lubrication order and LO 5-2805-208-14.

b. Perform the necessary daily preventive

Keep lubricants free of dust and sand. Keep

maintenance service.

lubrication points, and lubrication equipment

clean.

2-13. Operation Under Usual Conditions

b. Service engine air cleaner, sediment

a. It is essential that the operator know how

bowl, and blower air filter more frequently than

to perform every operation of which the ro-

during normal operation.

tary compressor is capable. Perform the daily

preventive maintenance services, (para 3-6).

c. Provide adequate protection to keep sand

and dirt from entering fuel tank when filling.

Service fuel filter as often as necessary to

in figure 2-3.

keep it free of foreign matter.

c. Stop rotary compressor as described in

sand by locating it near natural barriers and by

d. When the engine is operating, the air

wetting down the surrounding terrain if water

blower is directly driven at a preset pressure

is plentiful.

and no further operations need be performed

e. Clean the unit at frequent intervals with

other than the desired connection of either 1

an approved cleaning solvent or compressed

or 2 hoses. The air hose and fittings may be

air.

connected and disconnected when the rotary

compressor is operating.

f. Cover the unit when not in operation.