TM 5-4310-275-14

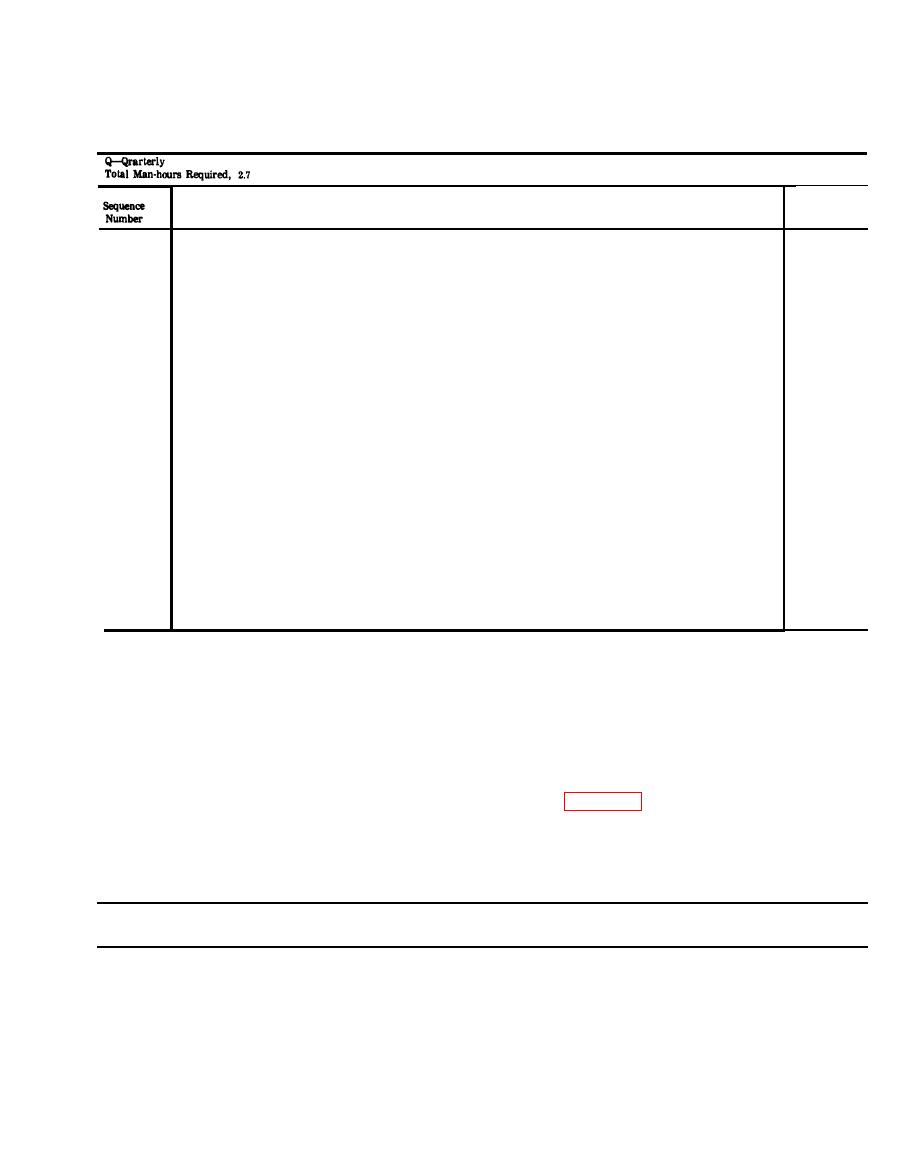

requirements. Refer to able 4-1 for the quarterly

b. The item numbers are listed consecutively

minimum

preventive maintenance services.

and

i n d i c a t e the sequence of

Work

Time

Item to be inspected

(M/ H)

Procedure

0.2

TOWING ATTACHMENTS

1

Check for bent or broken parts.

0.3

ENGINE FUEL FILTER

2

Service as required.

0.2

FUEL TANK

3

Clean fuel tank cap. Inspect for damaged screen. Check attaching hardware for tightness.

0.2

ENGINE CONTACT ASSEMBLIES

4

Adjust point gap at 0.018 in. (.0457 cm).

0.2

ENGINE AIR CLEANER

5

Service as required.

0.1

ENGINE AIR CLEANER INDICATOR

6

Check for red warning signal.

0.1

ENGINE OIL DIPSTICK

7

Check engine lubricating oil level. Add oil as required.

0.2

COMPRESSOR CRANKCASE FILL AND BREATHER ASSEMBLY

8

Clean and inspect for damaged parts.

0.2

9

TIRES

Check tire inflation pressure.

0.2

10

WHEEL ASSEMBLY

Inspect for worn bearings.

0.4

11

ENGINE SPARK PLUGS

Clean and adjust gap at 0.028 in. (.0711 cm) to 0.033 in. (.0838 cm).

0.2

12

AIR LINE FILTER

Replace filter element.

0.2

13

MOUNTING HARDWARE

Check for loose nuts and bolts.

Section V. TROUBLESHOOTING

4-10. General

NOTE

R e f e r t o TM 5-2804-257-14 for engine

This section provides information useful in

troubleshooting instructions.

diagnosing and correcting unsatisfactory

operation or failure of the compressor assembly

and its components. Each trouble symptom

bleshooting

stated is followed b y a list of probable causes. The

Refer to Table 4-2 for troubleshooting pertaining

possible remedy recommended is described op -

to organizational maintenance.

posite the probable cause. Any trouble beyond

the scope of organizational maintenance shall be

reported to direct support maintenance.

Table 4-2. TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. INSUFFICIENT AIR FLOW, LOW OUTLET PRESSURE, OR EXCESSIVE PUMP-UP TIME

Step 1. Inspect all connecting tubes and fittings for air leaks.

Tighten all connections, if the air leak continues, then replace the defective part with a similar item.

Step 2. Inspect the pressure relief valve for damage, defect (open) or escaping air.

Replace a defective pressure relief valve.

a. Removal.

(1) Disconnect all air lines.

(2) Remove all mounting hardware.

(3) Unscrew the relief valve.