TM 5-4310-275-14

pressure to 3300 50 psig (231.9900 3.5150 kg

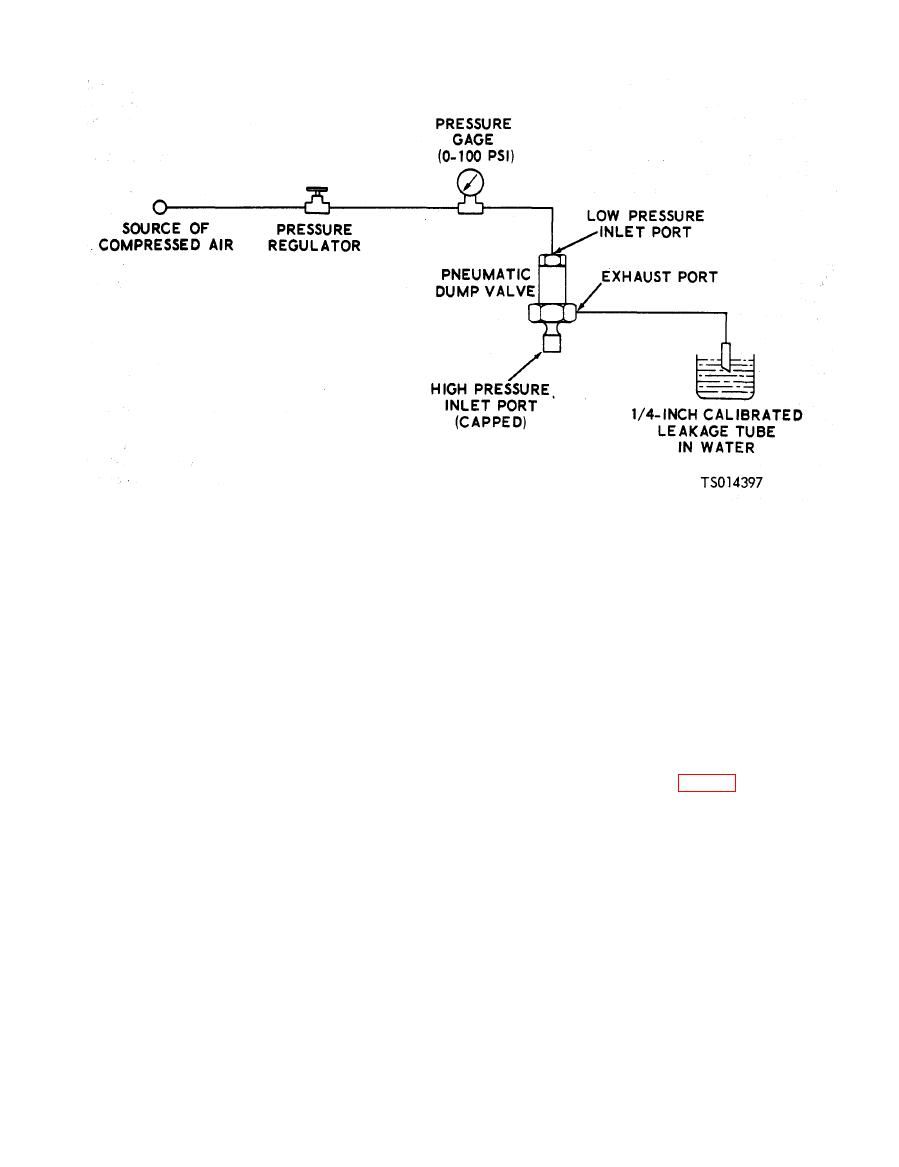

(5) Adjust pressure regulator to apply a

per sq cm), then shut off high pressure air supply.

pressure to 60 to 65 psig (4.2180 to 4.5695 kg per

sq cm) to low pressure inlet port.

(9) Piston in pneumatic dump valve should

remain closed to maintain high inlet air pressure.

(6) Leakage from exhaust port shall not

When it is evident that piston is closed, connect a

exceed three cubic centimeters per hour (one air

flowmeter to dump valve exhaust port. Measured

bubble every two minutes).

leakage shall not exceed five cubic inches per

(7) Use same test setup as illustrated in

minute.

Figure 6-9, except disconnect leakage tube from

(10) After completing tests, relieve air

exhaust port and connect an adjustable source of

pressure in test setup, disconnect pneumatic

high pressure compressed air to high pressure

dump valve and install on filter and separator

inlet port of pneumatic dump valve.

assembly.

(8) With an air pressure of 60 to 65 psig

g. Installation. Install the separator and filter

(4.2180 to 4.5695 kg per sq cm) applied to low

assembly and dump valve (fig. 4-7).

pressure inlet port, apply a gradually increasing

air pressure to high pressure inlet port. Increase