TM 5-4310-278-15

distortion, worn mounting surfaces, damaged

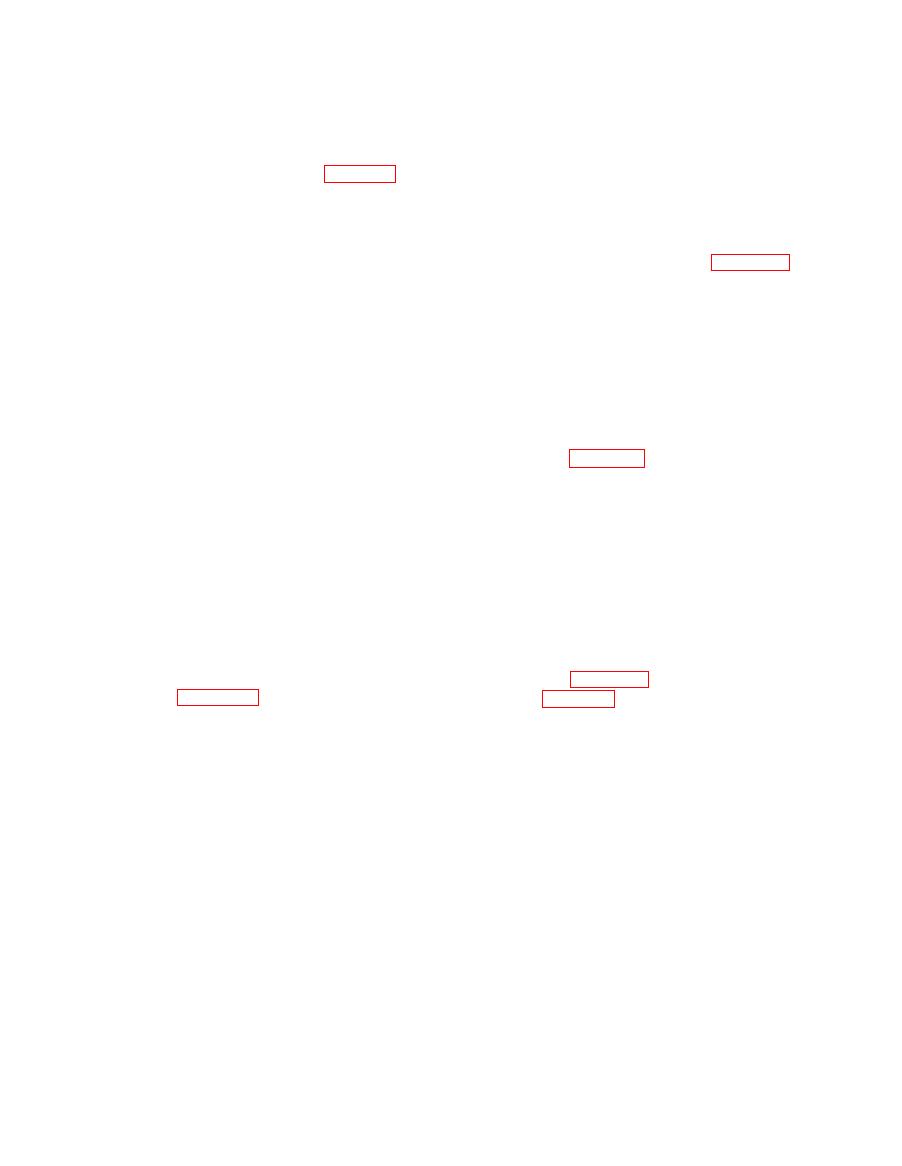

3-26. Coupling

k e y w a y s , and other damage.

a. Removal and Disassembly.

(4) Inspect spider for cracks, wear, de-

terioration or other damage.

(1) Remove rotary compressor (para 3-

(5) Replace all damaged parts.

28a).

c. Installation.

(2) Remove and disassemble c o u p l i n g

(1) Refer to figure 3-8 and install

parts as shown in figure 3-8.

coupling.

( 2 ) Install rotary compressor (para 3-

b. Cleaning and Inspection.

28c).

(1) Clean all metallic parts with approved

Note. Keep the setscrews on the driven half of the

cleaning solvent; dry thoroughly.

flexible coupling loose when the bearing housing is

(2) Wipe spider with clean cloth.

bolted to the engine flywheel housing. Then adjust the

(3) Inspect all metallic parts for cracks,

driven half of the coupling, and tighten the setscrews.

Section X. ROTARY COMPRESSOR

(2) Remove flexible coupling parts from

3-27. General

rotary compressor (para 3-26a).

The rotary compressor is secured to a cross

b. Cleaning and Inspection.

channel of the engine base and to the tran-

(1) Clean the exterior of the rotary com-

sition plate on the engine. It is driven by the

pressor with a clean cloth dampened with an

engine through a flexible coupling, one part

approved cleaning solvent; dry thoroughly.

of which is secured to the compressor shaft,

(2) Inspect the rotary compressor for any

while the other is secured to the engine crank-

external damage. Any trouble beyond the scope

shaft. Torque is transferred from the drive

of organizational maintenance shall be reported

portion to the driven portion by a resilient

to direct support maintenance.

spider.

c. Installation.

(1) Install coupling parts on rotary com-

a. Removal

pressor drive shaft (para 3-26c).

(1) Refer to figure 3-9 to remove rotary

(2) Refer to figure 3-9 to install com-

compressor,

pressor.