TM 5-4310-335-14

Section VIII. MAINTENANCE OF COMPRESSOR/COOLER ASSEMBLY

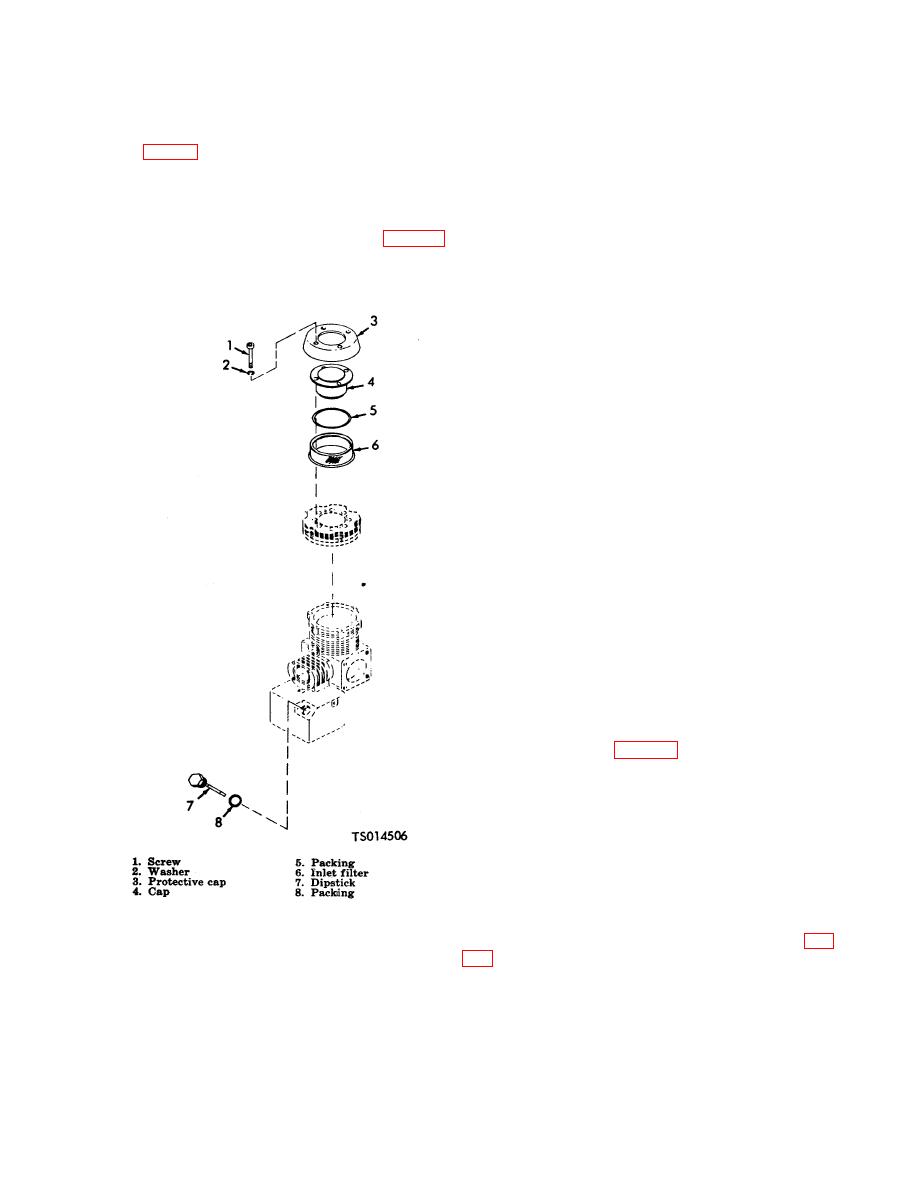

4-19. Air Compressor Inlet Air Filter

WARNING

a. General. The inlet air filter is located at the

Clean all parts in a well-ventilated area.

top of the first stage of the air compressor (1,

Avoid inhalation of solvent fumes and

prolonged exposure of skin to cleaning

to separate all dust, grit, dirt, debris and other

solvent. Wash exposed skin thoroughly.

foreign matter larger than 40 microns in size

Dry cleaning solvent (Fed. Spec. P-D680

from the inlet air in order to protect the air

and P-S-661) used to clean parts is

compressor stages.

potentially dangerous to personnel and

property. Do not use near open flame or

washers (2), protective cap (3), cap (4),

excessive heat. Flash point of solvent is

packing (5) and the inlet air filter (6).

1000 to 138 (380 to 590C). Clean the

F

c. Cleaning.

filter by agitating in a suitable cleaning

solvent, Federal Specification P-D-680.

clogging and damage.

e. Replacement. Replace a filter which will not

separate foreign matter.

f. Installation. Position the filter on the air

compressor first stage head. Install the

packing on the cap and install through center

of filter into the 1st stage head. Place the

protective cap over the cap and secure with

four washers and four screws. Torque the

screws to 17 inch-pounds (.20 kg-m) 22 inch-

pounds (.28 kg-m)

4-20.

Dipstick and Oil Strainer

a. General. The dipstick and oil strainer are

located in the air compressor oil sump. The

dipstick is used to determine the level of the

lubricating oil in the oil sump, and, the oil

strainer is used to filter out any foreign

particle that would be injurious to the air

compressor from the air compressor

lubricating system.

b. Removal.

(1) Turn counterclockwise and lift the

dipstick (7, fig. 4-1) from the oil sump;

remove preformed packing (8) from dipstick.

Determine presence of oil in sump. Discard

the packing.

NOTE

If lubricating oil is present in oil sump collect

the lubricating oil in a suitably sized container.

Check lubricating oil for presence of grit, dirt

or foreign matter.

(2) Unscrew the magnetic drain plug and

Figure 4-1. Inlet air filter and dipstick.

remove with preformed packing from oil sump.

(3) Disconnect the oil supply tube (27, fig.

4-10