TM 5-4310-335-14

the rear of the engine shaft with the screw (62). Tighten and torque the attaching screws to 235 inch-pounds

(2.72 kg m).

5-12.

Compressor/Cooler

a. General. The compressor is attached to the gasoline engine. The compressor assembly consists of

the compressor, fan, relief valves, fittings, clamps, intercoolers, aftercooler tube and tubes required to

produce and cool the compressed air delivered by the air compressor.

b. Removal.

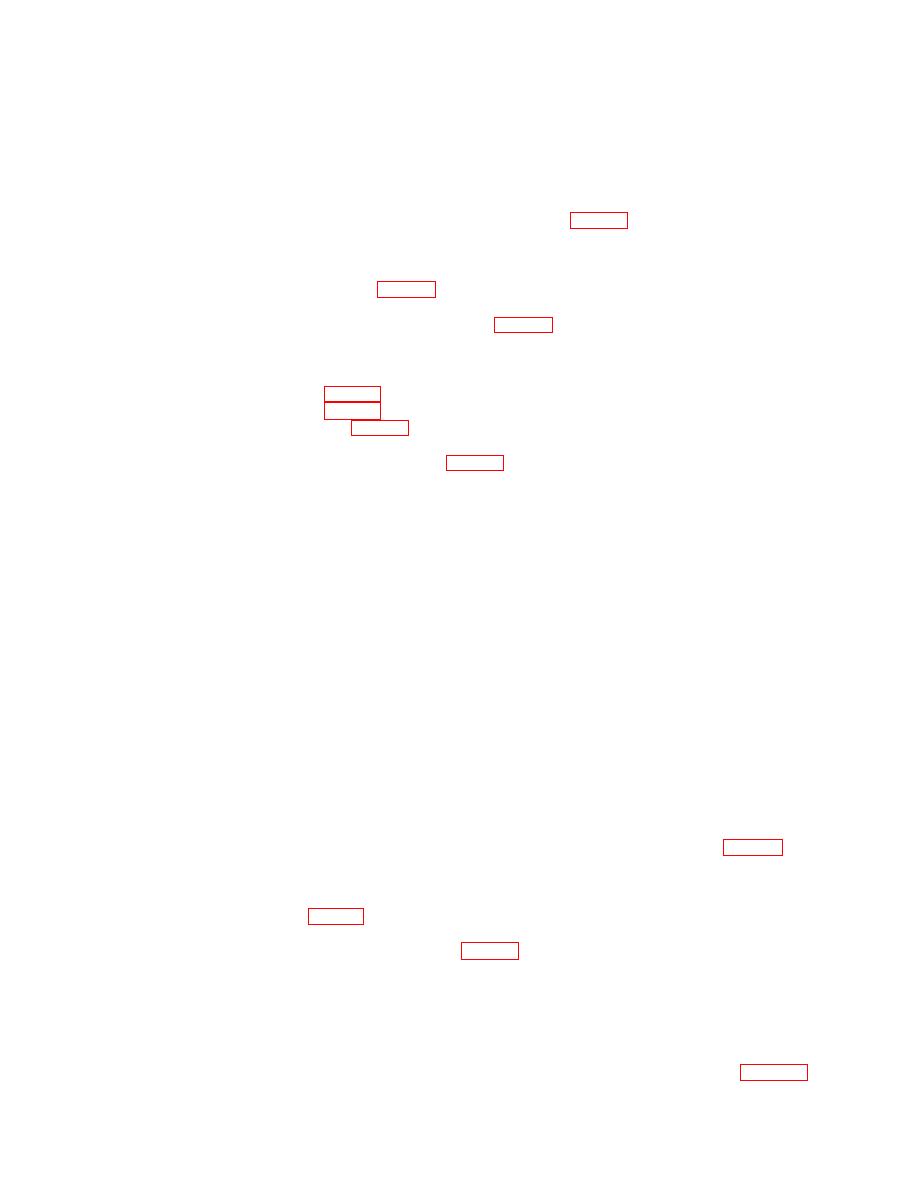

(1) Disconnect the flexible drive shaft from the angle drive (47, fig. 5-6).

(2) Remove rear support bracket (106, fig. 5 6) by reversing the attaching nuts (107), washers (108

and 109) and bolts (110). Coupling (49) may remain on either the angle drive (47) or the

compressor crankshaft.

(3) Disconnect the aftercooler (32, fig. 5-6) at the union (31). Remove nut (43), washers (44), screw

(45) which secure clamp (46) to the aftercooler.

(4) Disconnect the 4th stage relief valve tube (50, fig. 5-6) at the tee and at the relief valve (51).

Remove the tube.

(5) Place a suitable container under the compressor magnetic drain plug. Remove the plug and drain

the sump.

(6) Disconnect the nut (28, fig. 5-5), securing the flexible tubing to the oil pressure tube elbow (29).

(7) Disconnect the nut (37, fig. 5-5) securing the flexible tubing to the oil supply tube elbow.

(8) Remove the four bolts (59, fig. 5-6) and washers (58 and 57) which secure the compressor to the

engine (63).

(9) Slide the compressor-cooler assembly (56, fig. 5-6) to the rear of the cart sufficiently to disengage

the splines of adapter (61). Remove the assembly from the compressor.

WARNING

Dry cleaning solvent, P-D-680, used to clean parts is potentially dangerous to

personnel and property. Do not use near open flame or excessive heat.

Flash point of solvent is 100 138 (38 to 59 ).

F

F

C

C

c. Cleaning. Clean the compressor/cooler with cleaning solvent, Fed. Spec. P-D-680, and dry thoroughly,

using filtered compressed air.

d. Inspection.

(1) Inspect metal parts for dents, scratches, cracks, breaks, burrs, rough edges or other damage.

(2) Inspect tubing for cracks and deterioration.

(3) Inspect crankshaft coupling for scoring.

(4) Inspect compressor/cooler externally for damage and defective parts.

(5) Repair any damage or replace parts which obstruct moving parts or could cause damage to the

equipment.

e. Installation.

(1) Coat the external splines of the crankshaft adapter with grease, MIL-G-23827.

CAUTION

Exercise extreme care during installation to preclude damage to the intercoolers or

relief valves.

(2) Install the assembly to the compressor. Slide the compressor/cooler assembly (56, fig. 5-6) to the

front of the cart sufficiently to engage the splines of adapter (61).

(3) Install the four bolts (59) and washers (58 and 57) which secure the compressor to the engine

(63).

(4) Connect the nut (37, fig. 5-5), securing the flexible tubing to the oil supply tube elbow.

(5) Connect the nut (28), securing the flexible tubing to the oil pressure tube elbow (29).

(6) Connect the 4th stage relief valve tube (50, fig. 5-6) at the tee and at the relief valve (51). Install

the tube.

(7) Install nut (43), washers (44), screw (45) which secure clamp (46) to the aftercooler. Connect the

aftercooler (32) at the union (31).

(8) Install rear support bracket (106) by reversing the attaching nuts (107), washers (108 and 109)

and bolts (110).

(9) Connect the flexible drive shaft to the angle drive (47).

(10) Replenish the compressor oil supply after all lines are securely connected. Refer to table 5-2 for

torque values.

5-20