TM 5-4310-335-14

(aa) Remove shut-off valve (124).

(ab) Remove locknut (125), flatwasher (126), fillister head machine screw (127), flat- washers

(128 and 129) and cushioned clamp (130).

(ac) Remove locknut (131), flatwasher (132), screw (133), flatwashers (134 and 135) and

cushioned clamp (136).

(ad) Remove locknut (137), flatwasher (138), fillister head machine screw (139), flat- washer

(140), cushioned clamps (141 and 142) and tie wrap (143).

(ae) Remove tubing locknut (144), elbow (145), reducer bushing (146), tubing locknut (147),

elbow (148), tubing locknut (149), elbow (150) and unloader valve (151) leaving roof (152).

(2)

Fuel Tank Assembly.

(b) Remove cap with chain (3) and screen (4) leaving fuel tank (5).

(3)

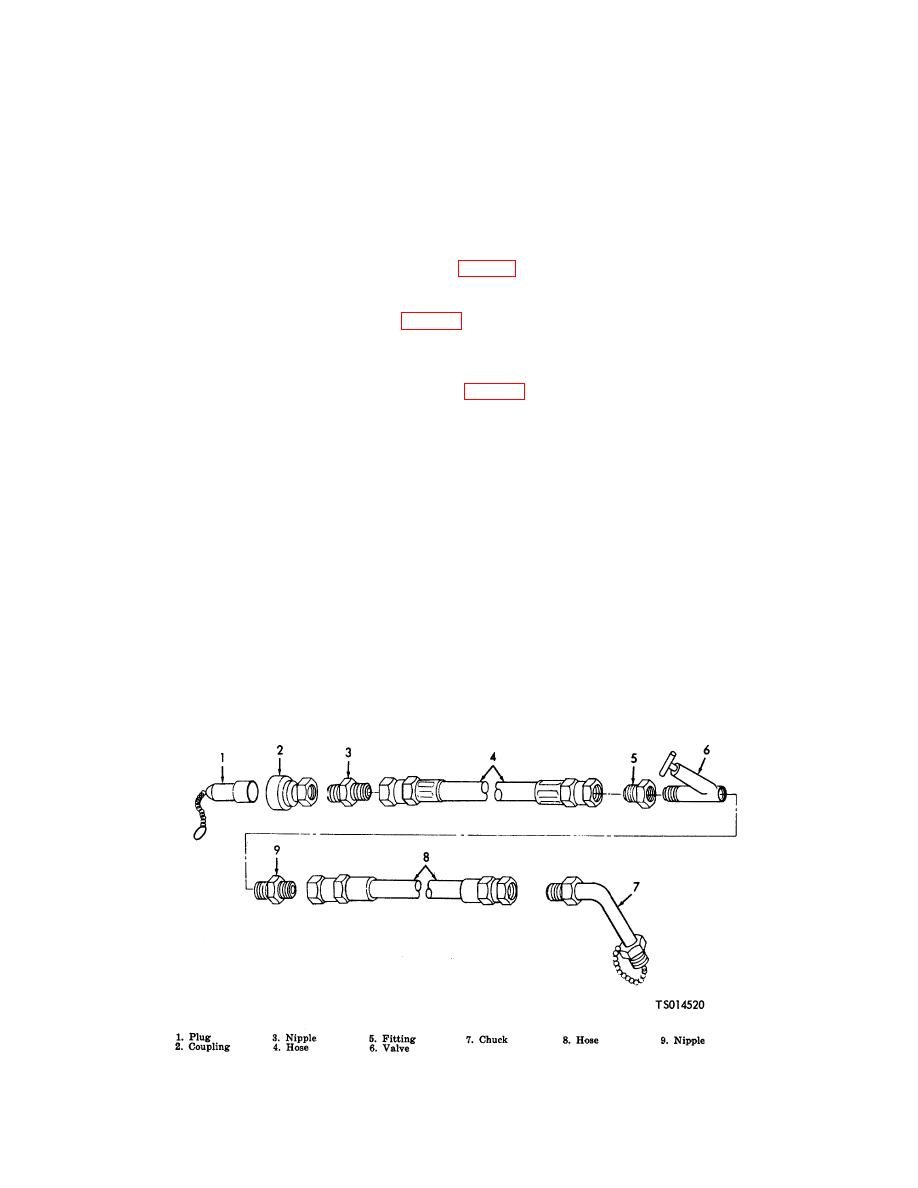

Charging Chuck Assembly.

fitting (5) and servicing valve (6).

(b) Remove charging chuck (7), charging hose (8) and pipe nipple (9).

(4)

Heater Cable Assembly.

screw (4) and protection cap (5).

(b) Remove lock hexagon nuts (6), flat- washers (7 and 8), hexagon head machine bolts (9),

and cable clamps (10).

(c) Remove plain hexagon nuts (11), flat- washers (12 and 13), fillister head machine screws

(14) and heater cable assembly (15) attached to moisture separator.

WARNING

Dry cleaning solvent, P-D-680, used to clean parts is potentially dangerous to

personnel and property. Do not use near open flame or excessive heat. Flash

point of solvent is 100 - 138 (38 to 59 ).

F

F

C

C

c.

Cleaning. Clean all tubing and fittings using cleaning solvent, Fed. Spec. P-D-680, and dry thoroughly

using compressed air.

d. Inspection.

(1) Inspect metal parts for dents, scratches, breaks, cracks, burrs, rough edges or other damage.

(2) Inspect plates for legibility.

(3) Inspect fuel tank strap for fraying, cuts and wear.

Figure 6-3. Charging Chuck Assembly

6-7