TM 5-4310-344-34

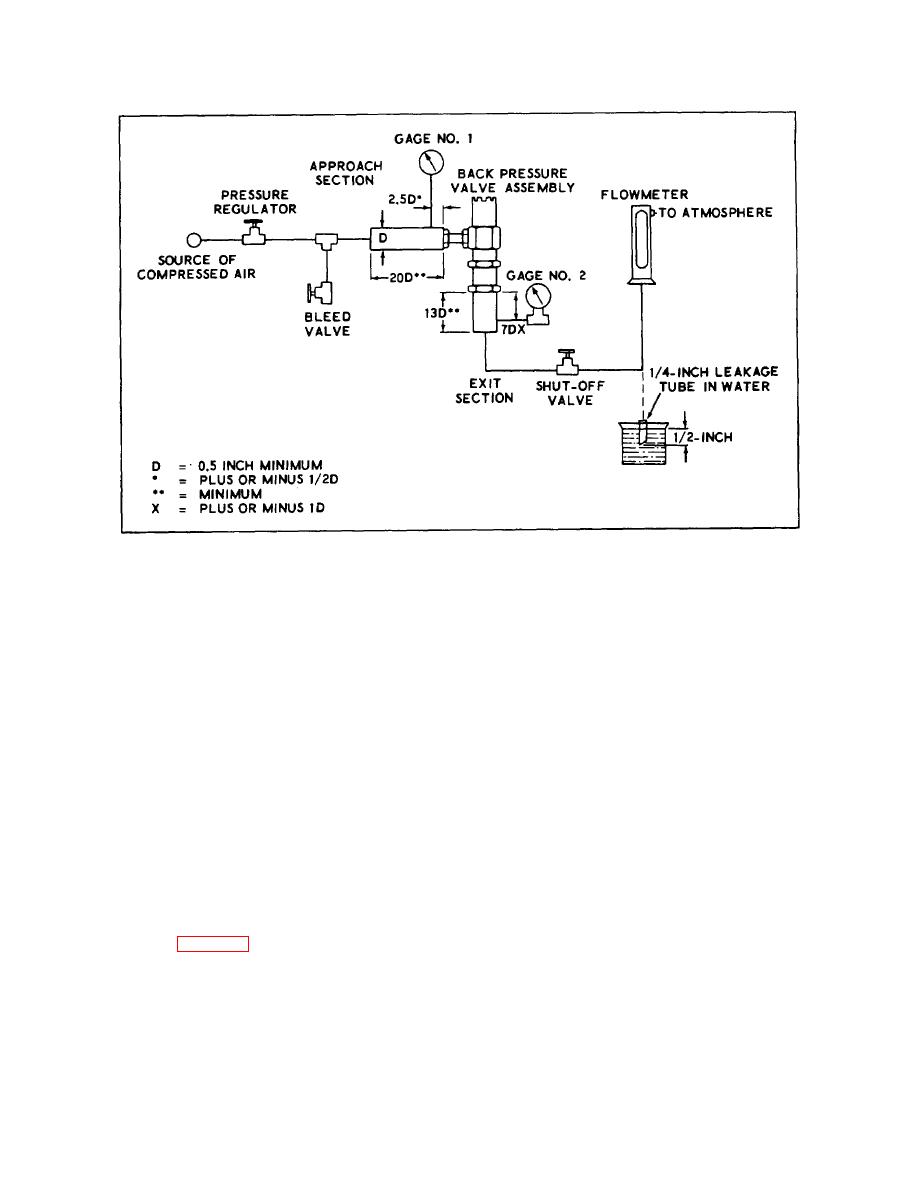

Figure 2-1. Back Pressure Valve Test Set-Up

a. Install retainer (12) and packing (11) in

as specified, the inlet pressure, gage No. 1, shall be

groove of piston (9). Install second packing (11) in

1600-to 1800-psig.

groove of piston seat (10).

c. To test for full flow with back pressure,

b. Install piston seat (10) and piston (9) in

adjust the pressure regulator and the shutoff valve until

valve body (13).

the outlet pressure, gage No. 2, is 1700 100 psig and

the flowmeter indicates a flow of 4.0 scfm. With the

outlet pressure as specified the inlet pressure shall not

c. Position tube fitting gaskets (5) in grooves

exceed 1800 psig as indicated at gage No. 1.

of inlet and outlet fittings (3 and 4). Screw fittings into

appropriate ports of valve body (13) and tighten to a

torque of 45 pound-inches.

d. Fully open the shutoff valve. Starting with

zero inlet pressure, open the pressure regulator to

d. Place spring (8), flanked by two spring

gradually increase inlet pressure to 1600 psig. With the

plates (7), into valve body (13). Screw valve cap (6)

inlet pressure as specified leakage through the back

into valve body until top surface of cap is approximately

pressure valve shall not exceed 5.0cc/min., as indicated

flush with upper edge of valve body.

by the flowmeter.

2-14.

TEST AND ADJUSTMENT.

e. With the shutoff valve fully open, adjust

the pressure regulator for inlet. pressure of 1800 psig.

Close pressure regulator to decrease the inlet pressure

a. Install the back pressure valve into the test

to 1600 psig. With the inlet pressure decreased as

setup illustrated in figure 2-1.

specified, leakage through the back pressure valve shall

not exceed 0.15 scfm as indicated by the flowmeter.

b. Open the shut-off valve fully. Open the

pressure regulator to gradually increase inlet pressure

f.

Close the shutoff valve and adjust the

until the flowmeter indicates a flow of 4.0 scfm, to test

pressure

for full flow pressure. With the flow

2-4